Microfactories focus on small-scale, flexible production systems designed for rapid customization and localized manufacturing, often reducing lead times and transportation costs. Gigafactories, in contrast, are massive facilities aimed at high-volume output and economies of scale, primarily used in industries like electric vehicle battery production to meet growing global demand. Discover more about how these contrasting factory models are reshaping the manufacturing landscape.

Why it is important

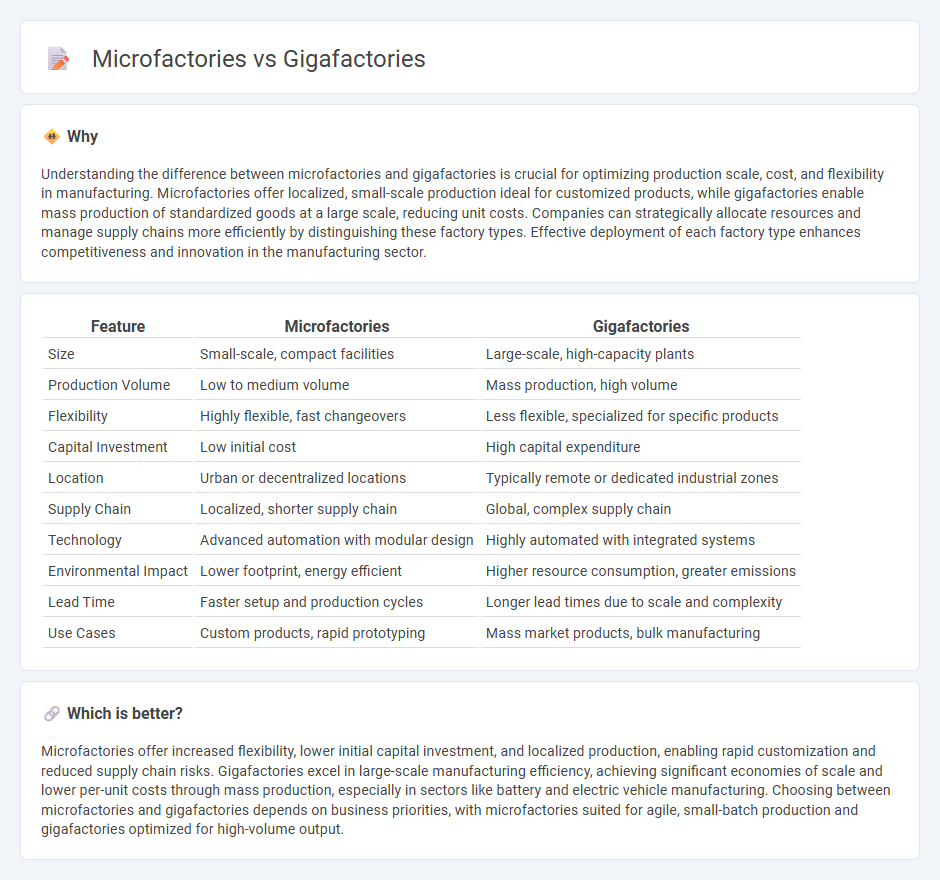

Understanding the difference between microfactories and gigafactories is crucial for optimizing production scale, cost, and flexibility in manufacturing. Microfactories offer localized, small-scale production ideal for customized products, while gigafactories enable mass production of standardized goods at a large scale, reducing unit costs. Companies can strategically allocate resources and manage supply chains more efficiently by distinguishing these factory types. Effective deployment of each factory type enhances competitiveness and innovation in the manufacturing sector.

Comparison Table

| Feature | Microfactories | Gigafactories |

|---|---|---|

| Size | Small-scale, compact facilities | Large-scale, high-capacity plants |

| Production Volume | Low to medium volume | Mass production, high volume |

| Flexibility | Highly flexible, fast changeovers | Less flexible, specialized for specific products |

| Capital Investment | Low initial cost | High capital expenditure |

| Location | Urban or decentralized locations | Typically remote or dedicated industrial zones |

| Supply Chain | Localized, shorter supply chain | Global, complex supply chain |

| Technology | Advanced automation with modular design | Highly automated with integrated systems |

| Environmental Impact | Lower footprint, energy efficient | Higher resource consumption, greater emissions |

| Lead Time | Faster setup and production cycles | Longer lead times due to scale and complexity |

| Use Cases | Custom products, rapid prototyping | Mass market products, bulk manufacturing |

Which is better?

Microfactories offer increased flexibility, lower initial capital investment, and localized production, enabling rapid customization and reduced supply chain risks. Gigafactories excel in large-scale manufacturing efficiency, achieving significant economies of scale and lower per-unit costs through mass production, especially in sectors like battery and electric vehicle manufacturing. Choosing between microfactories and gigafactories depends on business priorities, with microfactories suited for agile, small-batch production and gigafactories optimized for high-volume output.

Connection

Microfactories and Gigafactories are interconnected through their roles in scalable and efficient manufacturing processes, where microfactories focus on decentralized, flexible production of specialized components, and Gigafactories emphasize high-volume, centralized manufacturing, particularly in battery and electric vehicle industries. The integration of microfactories into supply chains allows Gigafactories to enhance customization and reduce lead times while maintaining economies of scale. This synergy accelerates innovation and responsiveness in manufacturing ecosystems, optimizing resource utilization and meeting diverse market demands.

Key Terms

Scale

Gigafactories, characterized by their massive production capacity, enable economies of scale crucial for reducing per-unit costs in industries like electric vehicle battery manufacturing. Microfactories emphasize localized, flexible, and smaller-scale production, enhancing customization and reducing logistics expenses but lacking the volume efficiency of gigafactories. Explore how these contrasting manufacturing scales impact supply chain dynamics and innovation by learning more about their strategic applications.

Automation

Gigafactories utilize large-scale automation systems integrating robotics and AI for high-volume production, significantly reducing labor costs and increasing efficiency in battery and electric vehicle manufacturing. Microfactories emphasize flexible, modular automation tailored for localized, small-batch production, enabling rapid customization and lower initial capital investment. Explore the evolving automation technologies shaping both gigafactory and microfactory paradigms to optimize manufacturing scalability and agility.

Supply Chain

Gigafactories streamline supply chains by centralizing production and reducing transportation costs, enabling mass production of batteries and electric vehicle components at scale. Microfactories offer localized manufacturing, enhancing supply chain resilience by shortening lead times and allowing customization based on regional demand. Explore how these contrasting factory models impact global supply chain strategies and efficiencies.

Source and External Links

Gigafactory - Tesla introduced the term "Gigafactory" in 2013 for its large-scale manufacturing plants producing battery cells, packs, drivetrains, and electric vehicles, with facilities worldwide and adoption of the term by other EV and clean tech companies.

What You Need to Know About Tesla's Gigafactories - Tesla currently operates five Gigafactories, including three in the U.S. (Nevada, New York, Texas) producing batteries, energy products, solar panels, and vehicles, and two international sites in China and Germany focused on vehicle and battery production.

What is a Gigafactory? | ATS - Gigafactories massively scale battery and EV component production, delivering benefits like job creation, cost reductions through economies of scale, innovation, and greener manufacturing by consolidating production operations under one roof.

dowidth.com

dowidth.com