Machine vision systems leverage advanced cameras and image processing algorithms to inspect and analyze products with high precision, enhancing quality control in manufacturing environments. IoT devices collect real-time data from machinery and processes, enabling predictive maintenance and operational efficiency through interconnected sensors and communication protocols. Explore how integrating machine vision and IoT technologies can revolutionize your manufacturing processes.

Why it is important

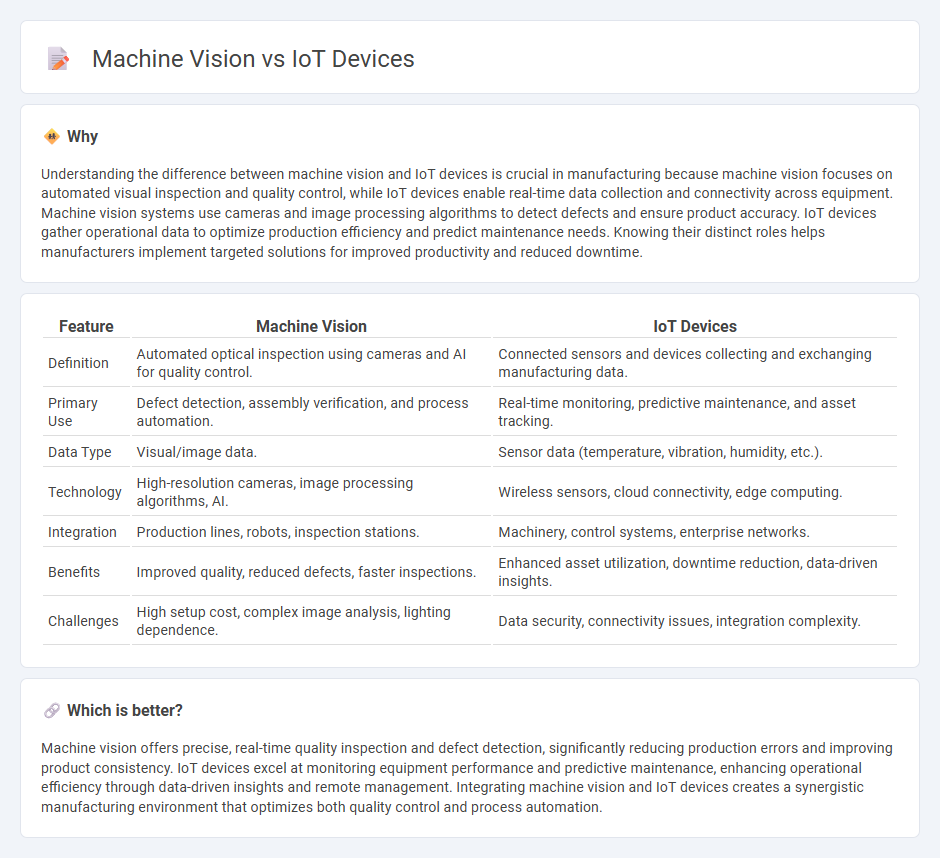

Understanding the difference between machine vision and IoT devices is crucial in manufacturing because machine vision focuses on automated visual inspection and quality control, while IoT devices enable real-time data collection and connectivity across equipment. Machine vision systems use cameras and image processing algorithms to detect defects and ensure product accuracy. IoT devices gather operational data to optimize production efficiency and predict maintenance needs. Knowing their distinct roles helps manufacturers implement targeted solutions for improved productivity and reduced downtime.

Comparison Table

| Feature | Machine Vision | IoT Devices |

|---|---|---|

| Definition | Automated optical inspection using cameras and AI for quality control. | Connected sensors and devices collecting and exchanging manufacturing data. |

| Primary Use | Defect detection, assembly verification, and process automation. | Real-time monitoring, predictive maintenance, and asset tracking. |

| Data Type | Visual/image data. | Sensor data (temperature, vibration, humidity, etc.). |

| Technology | High-resolution cameras, image processing algorithms, AI. | Wireless sensors, cloud connectivity, edge computing. |

| Integration | Production lines, robots, inspection stations. | Machinery, control systems, enterprise networks. |

| Benefits | Improved quality, reduced defects, faster inspections. | Enhanced asset utilization, downtime reduction, data-driven insights. |

| Challenges | High setup cost, complex image analysis, lighting dependence. | Data security, connectivity issues, integration complexity. |

Which is better?

Machine vision offers precise, real-time quality inspection and defect detection, significantly reducing production errors and improving product consistency. IoT devices excel at monitoring equipment performance and predictive maintenance, enhancing operational efficiency through data-driven insights and remote management. Integrating machine vision and IoT devices creates a synergistic manufacturing environment that optimizes both quality control and process automation.

Connection

Machine vision systems and IoT devices integrate through real-time data exchange to enhance manufacturing automation and quality control. IoT sensors collect environmental and operational data that machine vision algorithms analyze for defect detection, process optimization, and predictive maintenance. This connectivity enables seamless monitoring and adaptive decision-making on the factory floor, boosting efficiency and reducing downtime.

Key Terms

Connectivity

IoT devices rely on wireless connectivity protocols such as Wi-Fi, Bluetooth, and Zigbee to enable seamless data exchange and remote monitoring across diverse environments. Machine vision systems prioritize high-speed, low-latency connections like GigE Vision and USB3 Vision to process large volumes of image data in real time for precise industrial automation and quality control. Explore the latest advancements in connectivity technologies driving the integration of IoT devices and machine vision applications.

Image Processing

IoT devices leverage distributed sensors to collect and transmit data, while machine vision specializes in image processing using advanced algorithms to analyze visual information for real-time decision-making. Unlike general IoT sensors, machine vision systems employ techniques such as pattern recognition, object detection, and image segmentation to enable precise automation in manufacturing, quality control, and surveillance. Explore the nuances of image processing within these technologies to understand their distinct applications and capabilities.

Real-time Monitoring

IoT devices provide extensive real-time monitoring capabilities by collecting data from various sensors for smart environments, enabling immediate analysis and response. Machine vision leverages cameras and AI algorithms to offer precise visual inspection and object recognition, enhancing quality control and safety in manufacturing processes. Discover how integrating IoT and machine vision can revolutionize real-time monitoring systems.

Source and External Links

24 IoT Devices Connecting the World - Built In - IoT devices are hardware that connect wirelessly to the internet or a local network hub, enabling them to transmit and receive data for tasks ranging from home automation to industrial monitoring.

What Is the Internet of Things (IoT)? With Examples - Coursera - IoT is a network of physical devices--like smartwatches, medical monitors, and connected vehicles--that share data without human intervention, spanning consumer, industrial, and commercial uses.

What is IoT? - Internet of Things Explained - AWS - IoT refers to the collective network of connected devices and the technology enabling them to communicate with each other and the cloud, powered by advances in computer chips and telecommunications.

dowidth.com

dowidth.com