Automated guided vehicles (AGVs) and monorail systems are integral components of modern manufacturing for efficient material handling and transportation. AGVs offer flexible route navigation with programmable paths, while monorail systems provide fixed, high-speed conveyance suited for repetitive, linear workflows. Explore the advantages and applications of each technology to optimize your manufacturing operations.

Why it is important

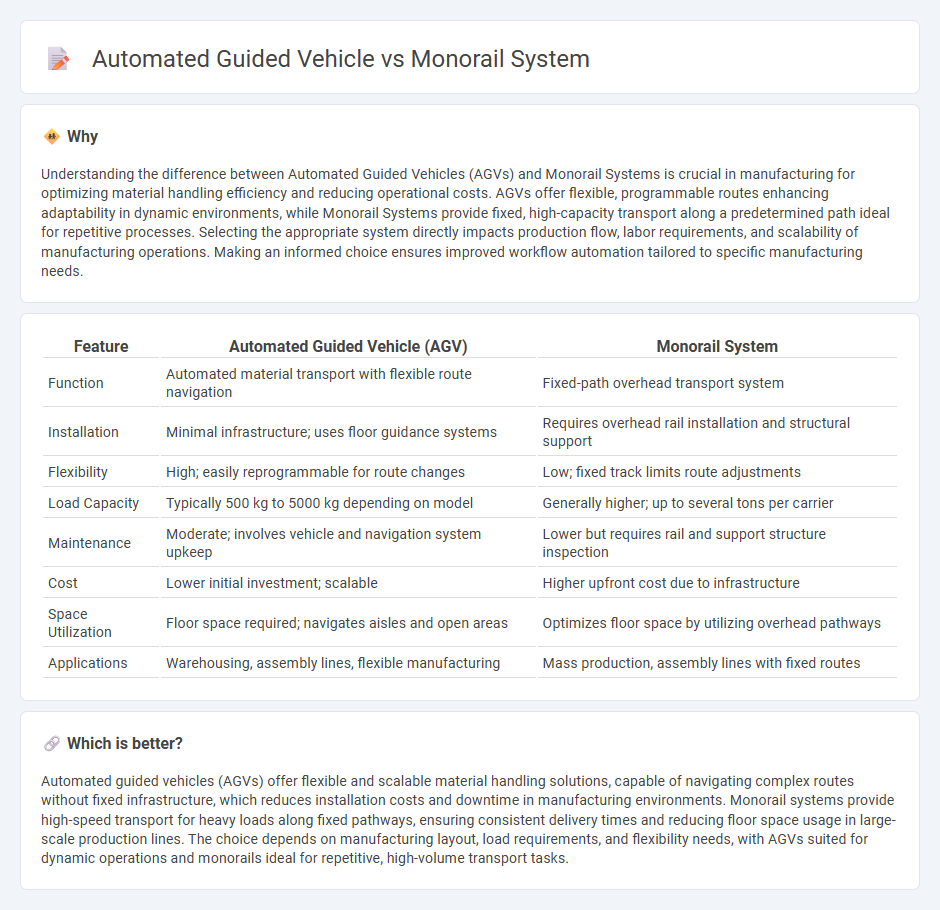

Understanding the difference between Automated Guided Vehicles (AGVs) and Monorail Systems is crucial in manufacturing for optimizing material handling efficiency and reducing operational costs. AGVs offer flexible, programmable routes enhancing adaptability in dynamic environments, while Monorail Systems provide fixed, high-capacity transport along a predetermined path ideal for repetitive processes. Selecting the appropriate system directly impacts production flow, labor requirements, and scalability of manufacturing operations. Making an informed choice ensures improved workflow automation tailored to specific manufacturing needs.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Monorail System |

|---|---|---|

| Function | Automated material transport with flexible route navigation | Fixed-path overhead transport system |

| Installation | Minimal infrastructure; uses floor guidance systems | Requires overhead rail installation and structural support |

| Flexibility | High; easily reprogrammable for route changes | Low; fixed track limits route adjustments |

| Load Capacity | Typically 500 kg to 5000 kg depending on model | Generally higher; up to several tons per carrier |

| Maintenance | Moderate; involves vehicle and navigation system upkeep | Lower but requires rail and support structure inspection |

| Cost | Lower initial investment; scalable | Higher upfront cost due to infrastructure |

| Space Utilization | Floor space required; navigates aisles and open areas | Optimizes floor space by utilizing overhead pathways |

| Applications | Warehousing, assembly lines, flexible manufacturing | Mass production, assembly lines with fixed routes |

Which is better?

Automated guided vehicles (AGVs) offer flexible and scalable material handling solutions, capable of navigating complex routes without fixed infrastructure, which reduces installation costs and downtime in manufacturing environments. Monorail systems provide high-speed transport for heavy loads along fixed pathways, ensuring consistent delivery times and reducing floor space usage in large-scale production lines. The choice depends on manufacturing layout, load requirements, and flexibility needs, with AGVs suited for dynamic operations and monorails ideal for repetitive, high-volume transport tasks.

Connection

Automated guided vehicles (AGVs) and monorail systems are integrated in manufacturing to streamline material handling and improve production efficiency. AGVs transport goods autonomously along predefined paths, while monorail systems provide overhead conveyance for heavy or bulky items, enabling seamless transfer between workstations. Combining AGVs with monorail systems creates a hybrid logistics network that optimizes workflow automation and reduces human intervention in factory environments.

Key Terms

Fixed-path transport

Monorail systems offer fixed-path transport with elevated tracks that provide high-capacity, fast, and collision-free movement ideal for urban transit or confined industrial settings. Automated Guided Vehicles (AGVs) navigate fixed paths on the ground using magnetic, optical, or laser guidance, allowing flexible route adjustments and easy integration within warehouses or manufacturing floors. Explore the benefits and applications of monorails versus AGVs to determine the best fixed-path transport solution for your operational needs.

Flexibility

Monorail systems offer fixed route flexibility with high efficiency in transporting goods along predetermined tracks, making them ideal for consistent, repetitive tasks in manufacturing or distribution centers. Automated guided vehicles (AGVs) provide superior route adaptability, capable of dynamically navigating changing environments and reconfiguring paths without physical alterations, enhancing operational responsiveness. Explore further to understand which technology best suits your facility's dynamic workflow needs.

Material handling automation

Monorail systems provide overhead, rail-based material transport optimized for heavy loads and fixed routes in industrial settings, enhancing efficiency with minimal floor space usage. Automated Guided Vehicles (AGVs) offer flexible, floor-level transport solutions with programmable navigation, ideal for dynamic material handling workflows and warehouse automation. Discover how integrating monorail systems and AGVs can optimize your material handling automation strategy.

dowidth.com

dowidth.com