Industrial metaverse integrates virtual reality and IoT to create immersive, real-time factory simulations that enhance operational efficiency, while additive manufacturing focuses on layer-by-layer 3D printing to produce customized, complex parts with reduced waste. Both technologies revolutionize production processes by enabling greater flexibility, faster prototyping, and improved resource management. Explore how these innovations are transforming modern manufacturing practices and driving Industry 4.0 forward.

Why it is important

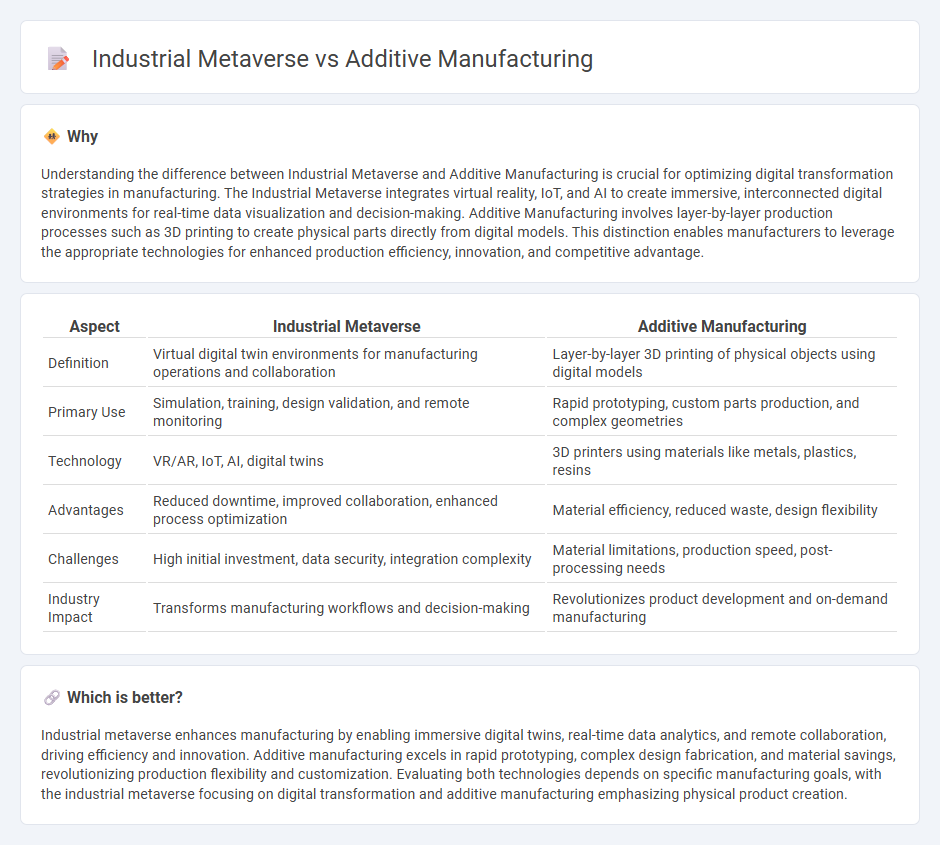

Understanding the difference between Industrial Metaverse and Additive Manufacturing is crucial for optimizing digital transformation strategies in manufacturing. The Industrial Metaverse integrates virtual reality, IoT, and AI to create immersive, interconnected digital environments for real-time data visualization and decision-making. Additive Manufacturing involves layer-by-layer production processes such as 3D printing to create physical parts directly from digital models. This distinction enables manufacturers to leverage the appropriate technologies for enhanced production efficiency, innovation, and competitive advantage.

Comparison Table

| Aspect | Industrial Metaverse | Additive Manufacturing |

|---|---|---|

| Definition | Virtual digital twin environments for manufacturing operations and collaboration | Layer-by-layer 3D printing of physical objects using digital models |

| Primary Use | Simulation, training, design validation, and remote monitoring | Rapid prototyping, custom parts production, and complex geometries |

| Technology | VR/AR, IoT, AI, digital twins | 3D printers using materials like metals, plastics, resins |

| Advantages | Reduced downtime, improved collaboration, enhanced process optimization | Material efficiency, reduced waste, design flexibility |

| Challenges | High initial investment, data security, integration complexity | Material limitations, production speed, post-processing needs |

| Industry Impact | Transforms manufacturing workflows and decision-making | Revolutionizes product development and on-demand manufacturing |

Which is better?

Industrial metaverse enhances manufacturing by enabling immersive digital twins, real-time data analytics, and remote collaboration, driving efficiency and innovation. Additive manufacturing excels in rapid prototyping, complex design fabrication, and material savings, revolutionizing production flexibility and customization. Evaluating both technologies depends on specific manufacturing goals, with the industrial metaverse focusing on digital transformation and additive manufacturing emphasizing physical product creation.

Connection

Industrial metaverse integrates digital twins and virtual simulations to optimize additive manufacturing processes, enhancing design accuracy and reducing production time. Real-time data exchange within industrial metaverse platforms enables seamless collaboration between engineers and manufacturers, leading to improved customization and faster prototyping. This synergy accelerates innovation cycles and drives efficiency in smart factories deploying advanced 3D printing technologies.

Key Terms

3D Printing

Additive manufacturing revolutionizes production by enabling layer-by-layer construction of complex 3D printed components, significantly reducing material waste and lead times compared to traditional methods. The industrial metaverse integrates virtual reality and IoT technologies to create immersive digital twins of manufacturing processes, allowing real-time monitoring, simulation, and optimization of 3D printing operations. Explore how combining additive manufacturing with the industrial metaverse is transforming the future of 3D printing innovation and efficiency.

Digital Twin

Additive manufacturing enhances production efficiency through precise layer-by-layer fabrication, while the industrial metaverse leverages digital twin technology to create immersive, real-time virtual replicas of physical assets for improved monitoring and predictive maintenance. Digital twins integrate IoT sensors, AI analytics, and machine learning models to optimize operational workflows and reduce downtime in smart factories. Discover detailed insights on how digital twin innovations are transforming manufacturing landscapes.

Virtual Reality

Virtual Reality in Additive Manufacturing enables immersive design reviews and real-time collaboration, enhancing precision and reducing prototyping cycles. In the Industrial Metaverse, VR integrates with digital twins and IoT data to create dynamic, interactive environments for training, maintenance, and system optimization. Explore how VR technologies transform manufacturing processes by bridging physical and virtual realms for improved efficiency.

Source and External Links

Additive Manufacturing, Explained - This article provides an overview of additive manufacturing, explaining its process, materials, and history, and its applications in industries such as aerospace and consumer products.

Additive Manufacturing | NIST - The National Institute of Standards and Technology discusses additive manufacturing as a technology that builds three-dimensional products layer by layer, highlighting its potential for various industries and need for standards development.

The 7 Categories of Additive Manufacturing - This resource outlines the seven categories of additive manufacturing processes, including vat photopolymerization, material jetting, and binder jetting, each using different materials and technologies.

dowidth.com

dowidth.com