Mass customization integrates advanced technologies and flexible processes to tailor products to individual customer preferences while maintaining near mass production efficiency. Lean manufacturing focuses on minimizing waste, optimizing workflows, and enhancing quality through standardized processes and continuous improvement. Explore how combining these approaches can revolutionize production strategies and drive competitive advantage.

Why it is important

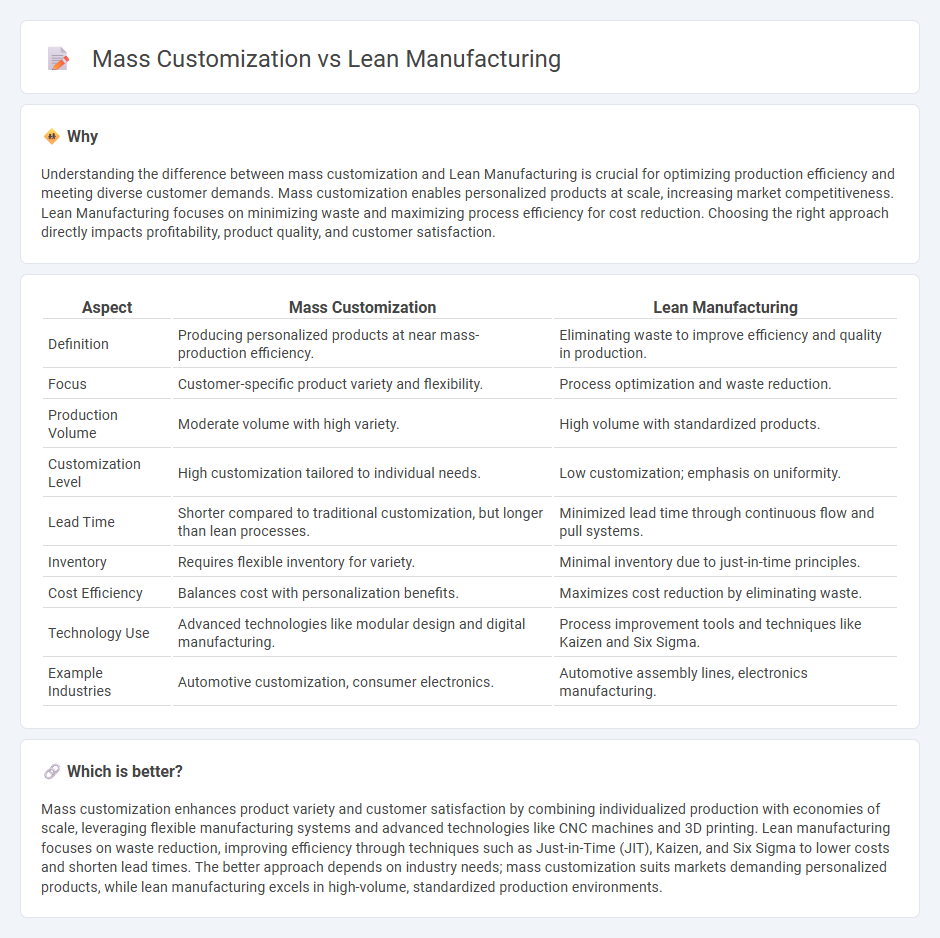

Understanding the difference between mass customization and Lean Manufacturing is crucial for optimizing production efficiency and meeting diverse customer demands. Mass customization enables personalized products at scale, increasing market competitiveness. Lean Manufacturing focuses on minimizing waste and maximizing process efficiency for cost reduction. Choosing the right approach directly impacts profitability, product quality, and customer satisfaction.

Comparison Table

| Aspect | Mass Customization | Lean Manufacturing |

|---|---|---|

| Definition | Producing personalized products at near mass-production efficiency. | Eliminating waste to improve efficiency and quality in production. |

| Focus | Customer-specific product variety and flexibility. | Process optimization and waste reduction. |

| Production Volume | Moderate volume with high variety. | High volume with standardized products. |

| Customization Level | High customization tailored to individual needs. | Low customization; emphasis on uniformity. |

| Lead Time | Shorter compared to traditional customization, but longer than lean processes. | Minimized lead time through continuous flow and pull systems. |

| Inventory | Requires flexible inventory for variety. | Minimal inventory due to just-in-time principles. |

| Cost Efficiency | Balances cost with personalization benefits. | Maximizes cost reduction by eliminating waste. |

| Technology Use | Advanced technologies like modular design and digital manufacturing. | Process improvement tools and techniques like Kaizen and Six Sigma. |

| Example Industries | Automotive customization, consumer electronics. | Automotive assembly lines, electronics manufacturing. |

Which is better?

Mass customization enhances product variety and customer satisfaction by combining individualized production with economies of scale, leveraging flexible manufacturing systems and advanced technologies like CNC machines and 3D printing. Lean manufacturing focuses on waste reduction, improving efficiency through techniques such as Just-in-Time (JIT), Kaizen, and Six Sigma to lower costs and shorten lead times. The better approach depends on industry needs; mass customization suits markets demanding personalized products, while lean manufacturing excels in high-volume, standardized production environments.

Connection

Mass customization and Lean Manufacturing are interconnected through their shared emphasis on efficiency and waste reduction in production processes. Lean Manufacturing principles streamline workflows and minimize excess inventory, enabling manufacturers to respond quickly to customer-specific demands inherent in mass customization. This synergy allows companies to deliver personalized products cost-effectively while maintaining high quality and fast turnaround times.

Key Terms

Just-in-Time (JIT)

Lean Manufacturing emphasizes Just-in-Time (JIT) to minimize inventory costs by producing only what is needed, when it is needed, thus reducing waste and enhancing efficiency. Mass customization blends JIT with flexible production processes, allowing for tailored products without sacrificing quick delivery or cost-effectiveness. Explore how JIT integrates into these strategies to optimize production flow and customer satisfaction.

Flexible Production Systems

Flexible Production Systems enable Lean Manufacturing by minimizing waste and optimizing workflow while supporting mass customization through adaptable processes that meet varied customer demands. These systems enhance responsiveness and efficiency by integrating automated equipment and real-time data analytics, allowing manufacturers to shift seamlessly between product variants without sacrificing quality or delivery speed. Discover how adopting Flexible Production Systems can transform your manufacturing strategy and drive competitive advantage.

Standardization

Lean manufacturing emphasizes standardization to minimize waste, streamline processes, and improve efficiency across production lines by implementing uniform procedures and quality controls. In contrast, mass customization balances standardization with flexibility, using modular designs and adaptable manufacturing systems to deliver personalized products without sacrificing efficiency. Explore how integrating these approaches can optimize production strategies and drive competitive advantage.

Source and External Links

Lean manufacturing - Wikipedia - Lean manufacturing is a method focused on reducing production and supplier response times by eliminating waste and improving efficiency, originally developed from the Toyota Production System and characterized by eliminating seven types of waste including overproduction, waiting, and defects.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing minimizes waste while maximizing productivity, based on principles like Kaizen (continuous improvement), and is widely applied by companies such as Toyota, Intel, and Nike, influencing many industries beyond manufacturing.

What is Lean Manufacturing? - Planview - Lean manufacturing applies Lean principles and tools to eliminate waste, optimize processes, and deliver value sustainably, using concepts like value stream mapping, pull systems, continuous improvement, and performance measurement.

dowidth.com

dowidth.com