Biofabrication utilizes biological materials and living cells to create complex tissue structures, enabling advancements in regenerative medicine and personalized healthcare. CNC machining employs computer-controlled machines to precisely shape metals and plastics, widely used in automotive, aerospace, and industrial manufacturing sectors. Explore the unique advantages and applications of biofabrication and CNC machining to understand their roles in modern manufacturing.

Why it is important

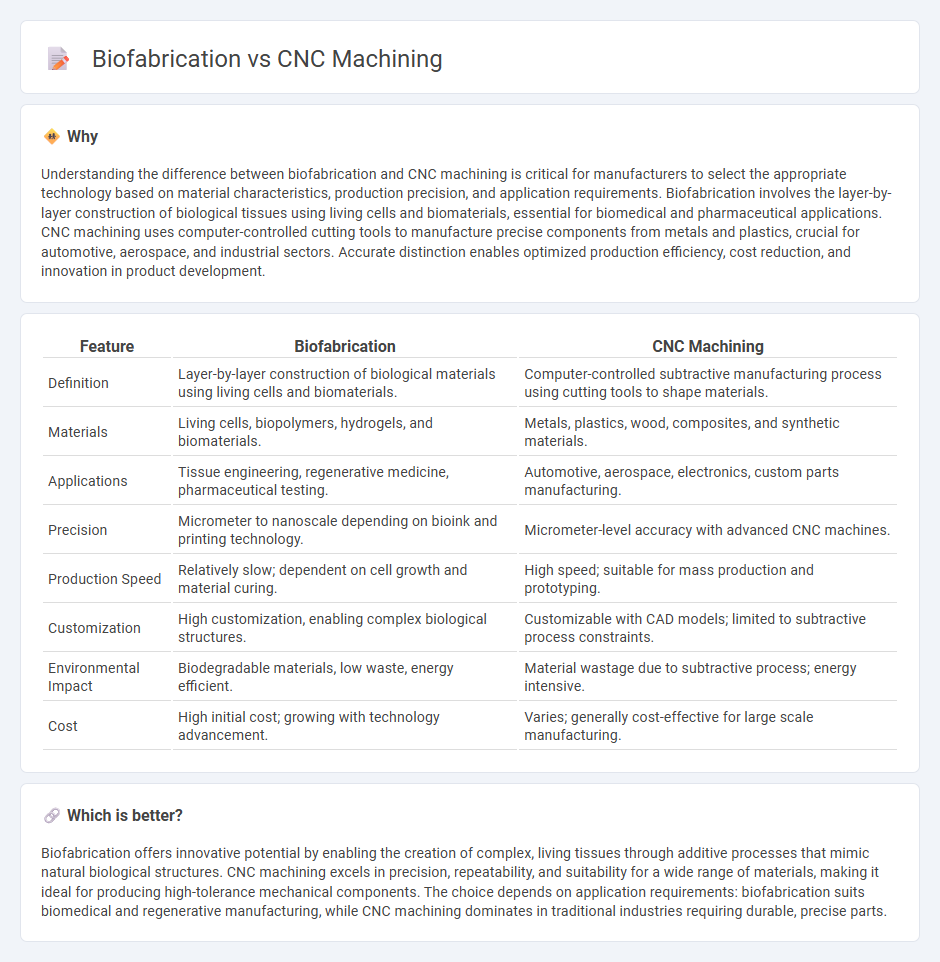

Understanding the difference between biofabrication and CNC machining is critical for manufacturers to select the appropriate technology based on material characteristics, production precision, and application requirements. Biofabrication involves the layer-by-layer construction of biological tissues using living cells and biomaterials, essential for biomedical and pharmaceutical applications. CNC machining uses computer-controlled cutting tools to manufacture precise components from metals and plastics, crucial for automotive, aerospace, and industrial sectors. Accurate distinction enables optimized production efficiency, cost reduction, and innovation in product development.

Comparison Table

| Feature | Biofabrication | CNC Machining |

|---|---|---|

| Definition | Layer-by-layer construction of biological materials using living cells and biomaterials. | Computer-controlled subtractive manufacturing process using cutting tools to shape materials. |

| Materials | Living cells, biopolymers, hydrogels, and biomaterials. | Metals, plastics, wood, composites, and synthetic materials. |

| Applications | Tissue engineering, regenerative medicine, pharmaceutical testing. | Automotive, aerospace, electronics, custom parts manufacturing. |

| Precision | Micrometer to nanoscale depending on bioink and printing technology. | Micrometer-level accuracy with advanced CNC machines. |

| Production Speed | Relatively slow; dependent on cell growth and material curing. | High speed; suitable for mass production and prototyping. |

| Customization | High customization, enabling complex biological structures. | Customizable with CAD models; limited to subtractive process constraints. |

| Environmental Impact | Biodegradable materials, low waste, energy efficient. | Material wastage due to subtractive process; energy intensive. |

| Cost | High initial cost; growing with technology advancement. | Varies; generally cost-effective for large scale manufacturing. |

Which is better?

Biofabrication offers innovative potential by enabling the creation of complex, living tissues through additive processes that mimic natural biological structures. CNC machining excels in precision, repeatability, and suitability for a wide range of materials, making it ideal for producing high-tolerance mechanical components. The choice depends on application requirements: biofabrication suits biomedical and regenerative manufacturing, while CNC machining dominates in traditional industries requiring durable, precise parts.

Connection

Biofabrication leverages advanced CNC machining techniques to create precise molds and scaffolds for tissue engineering and regenerative medicine. CNC machining enhances biofabrication by enabling the accurate shaping of biomaterials with micron-level precision, essential for developing complex biological structures. This integration drives innovation in manufacturing processes for medical implants, prosthetics, and organ-on-a-chip devices.

Key Terms

Subtractive Manufacturing (CNC Machining)

CNC machining employs subtractive manufacturing by precisely removing material from solid blocks using computer-controlled tools, ensuring high accuracy and repeatability for complex parts. Biofabrication, in contrast, largely follows additive approaches, building structures layer-by-layer with living cells or biomaterials, diverging from the subtractive method's material removal process. Discover more about the distinct techniques and applications of CNC machining versus biofabrication.

Additive Manufacturing (Biofabrication)

CNC machining offers precise subtractive manufacturing by removing material from a solid block, ideal for high-tolerance mechanical parts but limited in creating complex biological structures. Biofabrication, a subset of additive manufacturing, builds tissues and organs layer-by-layer using biocompatible materials and living cells, enabling innovative applications in regenerative medicine and personalized healthcare. Explore detailed comparisons of CNC machining and biofabrication techniques to understand their unique advantages and applications.

Material Biocompatibility

CNC machining offers precise control over biocompatible materials such as titanium and medical-grade polymers, ensuring high structural integrity for implants and devices. Biofabrication utilizes living cells and biomaterials like hydrogels to create tissue-like constructs that promote integration and reduce immune response, essential for regenerative medicine. Explore more to understand how these technologies revolutionize material biocompatibility in medical applications.

Source and External Links

Online CNC Machining Service | Get a Quote - CNC machining is an automated subtractive manufacturing process that uses computer-controlled end mills to transform solid blocks of material into precise parts based on 3D CAD models, widely used for prototyping and production with advantages like precision, repeatability, and quick turnaround.

Custom Online CNC Machining Services - CNC machining differs from traditional machining by using computer numerical control (CNC) to automate metal cutting, drilling, and milling processes with greater precision and repeatability by following codes and Cartesian coordinates from digital designs.

CNC machining: The manufacturing & design guide - CNC machining is a digital subtractive manufacturing technology that removes material from a solid workpiece to create parts with high accuracy and excellent physical properties directly from CAD files, differing fundamentally from additive (3D printing) and formative (injection molding) processes.

dowidth.com

dowidth.com