Machine vision inspection utilizes cameras and software algorithms to analyze surface defects and ensure quality control in manufacturing lines with real-time speed. Computed tomography (CT) scanning provides in-depth, three-dimensional imaging for internal structural analysis and defect detection in complex components. Explore the advantages and applications of both technologies to optimize manufacturing inspection processes.

Why it is important

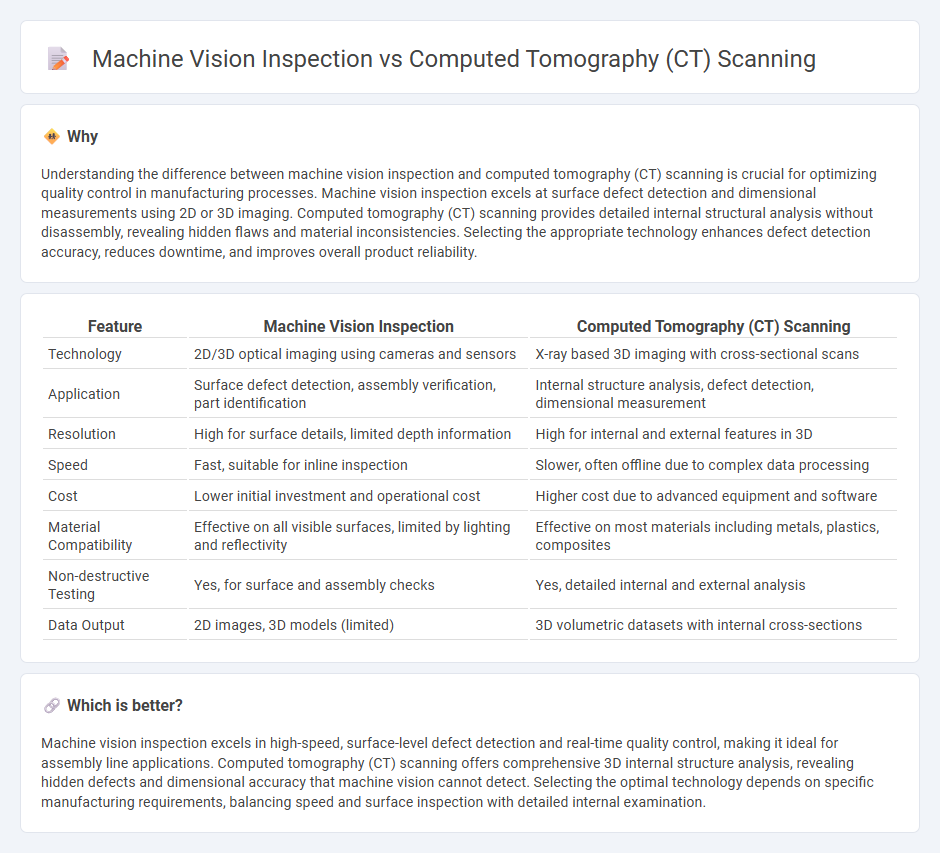

Understanding the difference between machine vision inspection and computed tomography (CT) scanning is crucial for optimizing quality control in manufacturing processes. Machine vision inspection excels at surface defect detection and dimensional measurements using 2D or 3D imaging. Computed tomography (CT) scanning provides detailed internal structural analysis without disassembly, revealing hidden flaws and material inconsistencies. Selecting the appropriate technology enhances defect detection accuracy, reduces downtime, and improves overall product reliability.

Comparison Table

| Feature | Machine Vision Inspection | Computed Tomography (CT) Scanning |

|---|---|---|

| Technology | 2D/3D optical imaging using cameras and sensors | X-ray based 3D imaging with cross-sectional scans |

| Application | Surface defect detection, assembly verification, part identification | Internal structure analysis, defect detection, dimensional measurement |

| Resolution | High for surface details, limited depth information | High for internal and external features in 3D |

| Speed | Fast, suitable for inline inspection | Slower, often offline due to complex data processing |

| Cost | Lower initial investment and operational cost | Higher cost due to advanced equipment and software |

| Material Compatibility | Effective on all visible surfaces, limited by lighting and reflectivity | Effective on most materials including metals, plastics, composites |

| Non-destructive Testing | Yes, for surface and assembly checks | Yes, detailed internal and external analysis |

| Data Output | 2D images, 3D models (limited) | 3D volumetric datasets with internal cross-sections |

Which is better?

Machine vision inspection excels in high-speed, surface-level defect detection and real-time quality control, making it ideal for assembly line applications. Computed tomography (CT) scanning offers comprehensive 3D internal structure analysis, revealing hidden defects and dimensional accuracy that machine vision cannot detect. Selecting the optimal technology depends on specific manufacturing requirements, balancing speed and surface inspection with detailed internal examination.

Connection

Machine vision inspection and computed tomography (CT) scanning are interconnected technologies enhancing manufacturing quality control by enabling detailed, non-destructive evaluation of components. Machine vision systems utilize cameras and algorithms to detect surface defects and assembly errors, while CT scanning provides 3D internal imaging to reveal hidden structural flaws. Together, these methods offer comprehensive inspection solutions that improve defect detection accuracy and reduce production downtime.

Key Terms

3D Imaging

Computed tomography (CT) scanning excels in 3D imaging by providing high-resolution volumetric data that reveals internal structures non-destructively, making it ideal for medical diagnostics and material analysis. Machine vision inspection, while offering rapid 2D and limited 3D surface imaging through cameras and sensors, primarily focuses on external feature detection and quality control in industrial applications. Explore the differences and applications in 3D imaging technologies to understand which solution best fits your specific needs.

Defect Detection

Computed tomography (CT) scanning offers high-resolution, volumetric imaging that enables precise identification of internal defects such as voids, cracks, and inclusions in complex materials and assemblies. Machine vision inspection relies on surface imaging and pattern recognition algorithms to detect visible defects like scratches, misalignments, and surface contamination rapidly and cost-effectively. Explore the comparative advantages and applications of CT scanning versus machine vision inspection for optimizing defect detection strategies.

Non-Destructive Testing

Computed tomography (CT) scanning offers high-resolution, three-dimensional imaging for non-destructive testing (NDT), enabling detailed internal inspection of complex components without disassembly. Machine vision inspection utilizes cameras and image processing algorithms to rapidly analyze surface defects and assembly accuracy, providing efficient quality control in industrial applications. Explore further to understand how integrating CT scanning and machine vision can optimize non-destructive testing processes.

Source and External Links

CT scan - Wikipedia - A computed tomography scan (CT scan) is a medical imaging technique using a rotating X-ray tube and detectors to produce detailed cross-sectional images of the body, helpful for diagnosing and evaluating many conditions, including cancers, especially when MRI is contraindicated.

Computed Tomography (CT) Scan | Johns Hopkins Medicine - A CT scan uses X-rays and computer technology to create detailed images of the inside of the body, providing more detail than standard X-rays and enabling diagnosis of tumors, internal bleeding, injuries, and guidance for biopsies and surgeries.

CT scan - Mayo Clinic - A CT scan is an imaging test that combines X-ray measurements and computer processing to create detailed cross-sectional images of bones, blood vessels, and soft tissues, useful for diagnosing diseases, guiding treatments, and evaluating injuries or conditions like tumors and blood clots.

dowidth.com

dowidth.com