Factory as a Service (FaaS) offers scalable, on-demand manufacturing capabilities without the need for heavy capital investment, contrasting with Original Equipment Manufacturers (OEMs) who produce components or finished goods under their brand ownership and quality standards. FaaS leverages cloud-based platforms and flexible production lines to optimize resource utilization and accelerate time-to-market, while OEMs maintain full control over design, intellectual property, and supply chain management. Explore how these manufacturing models can drive innovation and operational efficiency tailored to your production needs.

Why it is important

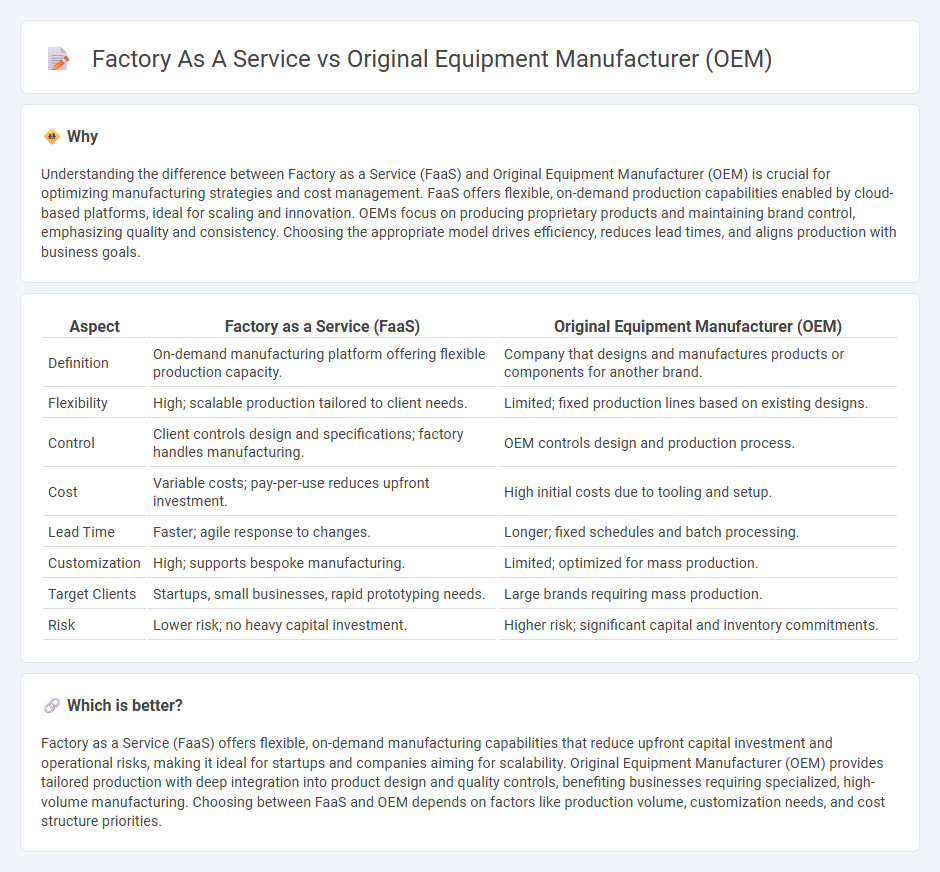

Understanding the difference between Factory as a Service (FaaS) and Original Equipment Manufacturer (OEM) is crucial for optimizing manufacturing strategies and cost management. FaaS offers flexible, on-demand production capabilities enabled by cloud-based platforms, ideal for scaling and innovation. OEMs focus on producing proprietary products and maintaining brand control, emphasizing quality and consistency. Choosing the appropriate model drives efficiency, reduces lead times, and aligns production with business goals.

Comparison Table

| Aspect | Factory as a Service (FaaS) | Original Equipment Manufacturer (OEM) |

|---|---|---|

| Definition | On-demand manufacturing platform offering flexible production capacity. | Company that designs and manufactures products or components for another brand. |

| Flexibility | High; scalable production tailored to client needs. | Limited; fixed production lines based on existing designs. |

| Control | Client controls design and specifications; factory handles manufacturing. | OEM controls design and production process. |

| Cost | Variable costs; pay-per-use reduces upfront investment. | High initial costs due to tooling and setup. |

| Lead Time | Faster; agile response to changes. | Longer; fixed schedules and batch processing. |

| Customization | High; supports bespoke manufacturing. | Limited; optimized for mass production. |

| Target Clients | Startups, small businesses, rapid prototyping needs. | Large brands requiring mass production. |

| Risk | Lower risk; no heavy capital investment. | Higher risk; significant capital and inventory commitments. |

Which is better?

Factory as a Service (FaaS) offers flexible, on-demand manufacturing capabilities that reduce upfront capital investment and operational risks, making it ideal for startups and companies aiming for scalability. Original Equipment Manufacturer (OEM) provides tailored production with deep integration into product design and quality controls, benefiting businesses requiring specialized, high-volume manufacturing. Choosing between FaaS and OEM depends on factors like production volume, customization needs, and cost structure priorities.

Connection

Factory as a Service (FaaS) enables Original Equipment Manufacturers (OEMs) to outsource production processes, leveraging scalable and flexible manufacturing resources without heavy capital investment. OEMs benefit from FaaS by gaining access to advanced technologies and rapid prototyping capabilities that align with their product development cycles. This partnership streamlines supply chain management and accelerates time-to-market for new products.

Key Terms

Supply Chain Integration

Original Equipment Manufacturer (OEM) models traditionally control product design and manufacturing, focusing on vertical supply chain integration to maintain quality and brand consistency. Factory as a Service (FaaS) leverages scalable, on-demand manufacturing solutions, allowing companies to optimize supply chain agility, reduce capital expenditure, and integrate third-party production seamlessly. Explore how shifting from OEM to FaaS can transform supply chain management and operational efficiency.

Production Ownership

Original Equipment Manufacturer (OEM) retains full production ownership, managing design, manufacturing, and quality control to ensure brand integrity and customization. Factory as a Service (FaaS) offers outsourced production capacity, allowing companies to leverage external facilities without direct ownership or operational responsibilities. Explore more to understand which model best suits your business production strategy.

Customization Flexibility

Original Equipment Manufacturers (OEMs) offer limited customization flexibility due to their standardized production processes designed for mass output, whereas Factory as a Service (FaaS) platforms provide highly adaptable manufacturing solutions tailored to specific client requirements through modular and scalable systems. FaaS enables quicker iteration and adjustments in product design, accommodating unique customer specifications and shorter production runs, making it ideal for startups and niche markets. Explore how FaaS can transform your manufacturing strategy with enhanced customization options and agile production capabilities.

Source and External Links

Original equipment manufacturer - Wikipedia - An original equipment manufacturer (OEM) is a company that produces parts and equipment that may be marketed by another company; in automotive, OEM parts are those made by the original manufacturer used during vehicle assembly, as opposed to aftermarket parts from different companies.

What is OEM? // Original Equipment Manufacturing Guide and How ... - OEM is a business model where a company manufactures products or parts based on another company's design and specifications, allowing the client to focus on R&D, marketing, and sales while the OEM handles production.

What Are Original Equipment Manufacturers (OEM)? - MakerVerse - OEMs design and produce components or products integrated into larger systems, ensuring quality and consistency, with their goods sold under another company's branding in industries like automotive, aerospace, and electronics.

dowidth.com

dowidth.com