Microfactories offer compact, scalable production units capable of localized manufacturing, reducing transportation costs and enabling rapid customization. Distributed manufacturing leverages a network of geographically dispersed facilities to enhance supply chain resilience and reduce lead times by closer proximity to end consumers. Explore how these innovative manufacturing models are reshaping efficiency and responsiveness in production today.

Why it is important

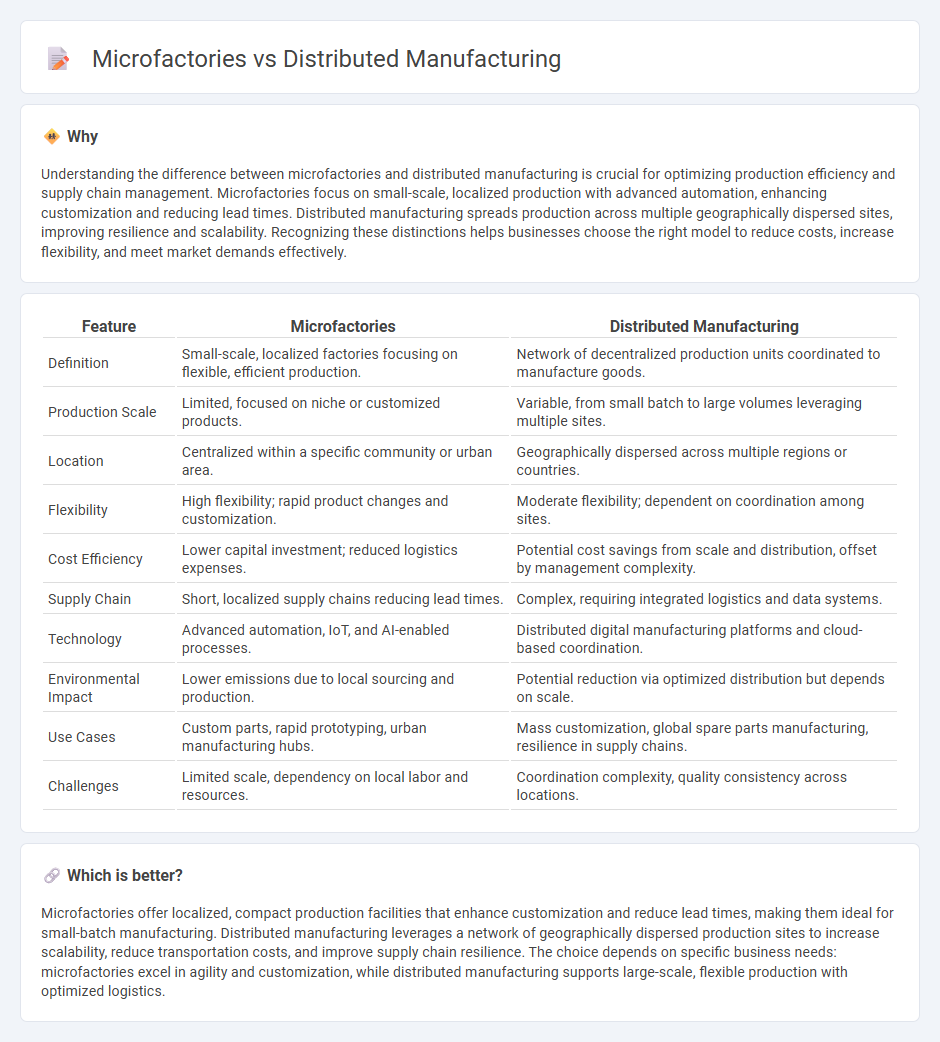

Understanding the difference between microfactories and distributed manufacturing is crucial for optimizing production efficiency and supply chain management. Microfactories focus on small-scale, localized production with advanced automation, enhancing customization and reducing lead times. Distributed manufacturing spreads production across multiple geographically dispersed sites, improving resilience and scalability. Recognizing these distinctions helps businesses choose the right model to reduce costs, increase flexibility, and meet market demands effectively.

Comparison Table

| Feature | Microfactories | Distributed Manufacturing |

|---|---|---|

| Definition | Small-scale, localized factories focusing on flexible, efficient production. | Network of decentralized production units coordinated to manufacture goods. |

| Production Scale | Limited, focused on niche or customized products. | Variable, from small batch to large volumes leveraging multiple sites. |

| Location | Centralized within a specific community or urban area. | Geographically dispersed across multiple regions or countries. |

| Flexibility | High flexibility; rapid product changes and customization. | Moderate flexibility; dependent on coordination among sites. |

| Cost Efficiency | Lower capital investment; reduced logistics expenses. | Potential cost savings from scale and distribution, offset by management complexity. |

| Supply Chain | Short, localized supply chains reducing lead times. | Complex, requiring integrated logistics and data systems. |

| Technology | Advanced automation, IoT, and AI-enabled processes. | Distributed digital manufacturing platforms and cloud-based coordination. |

| Environmental Impact | Lower emissions due to local sourcing and production. | Potential reduction via optimized distribution but depends on scale. |

| Use Cases | Custom parts, rapid prototyping, urban manufacturing hubs. | Mass customization, global spare parts manufacturing, resilience in supply chains. |

| Challenges | Limited scale, dependency on local labor and resources. | Coordination complexity, quality consistency across locations. |

Which is better?

Microfactories offer localized, compact production facilities that enhance customization and reduce lead times, making them ideal for small-batch manufacturing. Distributed manufacturing leverages a network of geographically dispersed production sites to increase scalability, reduce transportation costs, and improve supply chain resilience. The choice depends on specific business needs: microfactories excel in agility and customization, while distributed manufacturing supports large-scale, flexible production with optimized logistics.

Connection

Microfactories enable distributed manufacturing by decentralizing production into small, flexible units closer to end consumers, reducing transportation costs and lead times. Distributed manufacturing leverages these compact facilities to customize products rapidly and respond to market demands with greater agility. This synergy enhances supply chain resilience and supports sustainable manufacturing practices through localized production.

Key Terms

Decentralization

Distributed manufacturing leverages a network of interconnected production sites, enabling localized production that reduces transportation costs and lead times while enhancing flexibility. Microfactories operate as compact, highly automated facilities designed for small-batch, customized production, emphasizing rapid reconfiguration and responsiveness to market demands. Explore the advantages and strategic impact of decentralized production models to optimize your manufacturing approach.

Scalability

Distributed manufacturing enables scalability by leveraging multiple decentralized production sites, reducing lead times and increasing flexibility in meeting demand fluctuations. Microfactories focus on compact, highly automated units designed for localized, small-batch production, offering rapid scalability through replication but limited by physical space. Explore the advantages and challenges of each approach to determine the best fit for your scalable manufacturing strategy.

Customization

Distributed manufacturing enables localized production by leveraging networked facilities, reducing lead times and allowing customization closer to the end consumer. Microfactories offer highly flexible, small-scale production units that integrate advanced automation and digital tools to tailor products to individual specifications. Explore these innovative approaches to understand how customization drives efficiency and personalization in modern manufacturing.

Source and External Links

Distributed manufacturing benefits: Revolutionizing production - Distributed manufacturing is a model where production is spread across a network of smaller, geographically dispersed facilities coordinated digitally, enabling localized, adaptable production closer to consumers, reducing shipping costs, and allowing more tailored products using technologies like 3D printing and IoT.

Distributed Manufacturing: The Way of the Future? - Distributed manufacturing organizes production across multiple local sites near consumers, using modular design, on-demand production, and recycling to minimize waste and respond efficiently to local market needs.

Distributed manufacturing - Wikipedia - Distributed manufacturing involves geographically dispersed manufacturing facilities coordinated by IT to reduce shipping costs and enable product customization, potentially involving decentralized additive manufacturing and cloud-based production networks.

dowidth.com

dowidth.com