Lights out factories leverage automation and robotics to achieve fully unattended production, maximizing efficiency and minimizing human error. Mass customization focuses on tailoring products to individual customer preferences while maintaining cost-effective manufacturing processes. Explore the benefits and challenges of both approaches to understand their impact on modern manufacturing.

Why it is important

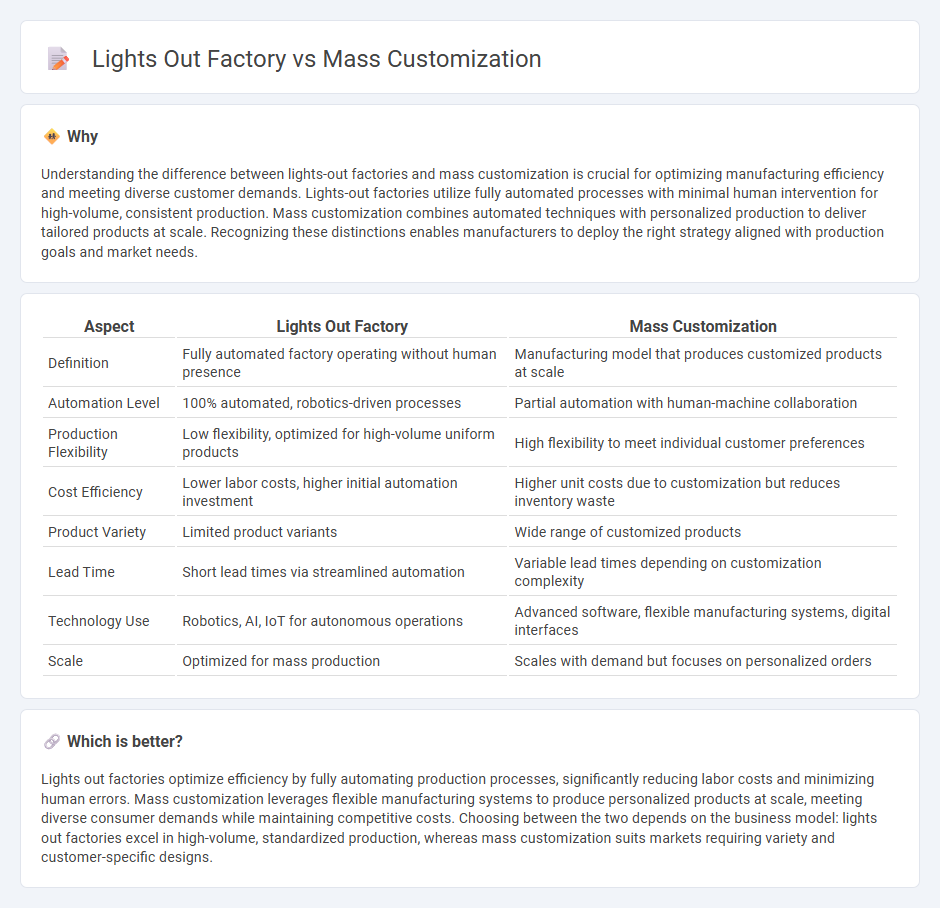

Understanding the difference between lights-out factories and mass customization is crucial for optimizing manufacturing efficiency and meeting diverse customer demands. Lights-out factories utilize fully automated processes with minimal human intervention for high-volume, consistent production. Mass customization combines automated techniques with personalized production to deliver tailored products at scale. Recognizing these distinctions enables manufacturers to deploy the right strategy aligned with production goals and market needs.

Comparison Table

| Aspect | Lights Out Factory | Mass Customization |

|---|---|---|

| Definition | Fully automated factory operating without human presence | Manufacturing model that produces customized products at scale |

| Automation Level | 100% automated, robotics-driven processes | Partial automation with human-machine collaboration |

| Production Flexibility | Low flexibility, optimized for high-volume uniform products | High flexibility to meet individual customer preferences |

| Cost Efficiency | Lower labor costs, higher initial automation investment | Higher unit costs due to customization but reduces inventory waste |

| Product Variety | Limited product variants | Wide range of customized products |

| Lead Time | Short lead times via streamlined automation | Variable lead times depending on customization complexity |

| Technology Use | Robotics, AI, IoT for autonomous operations | Advanced software, flexible manufacturing systems, digital interfaces |

| Scale | Optimized for mass production | Scales with demand but focuses on personalized orders |

Which is better?

Lights out factories optimize efficiency by fully automating production processes, significantly reducing labor costs and minimizing human errors. Mass customization leverages flexible manufacturing systems to produce personalized products at scale, meeting diverse consumer demands while maintaining competitive costs. Choosing between the two depends on the business model: lights out factories excel in high-volume, standardized production, whereas mass customization suits markets requiring variety and customer-specific designs.

Connection

Lights-out factories leverage full automation and robotics to operate without human intervention, enabling continuous 24/7 production. This seamless automation supports mass customization by rapidly adjusting manufacturing processes and equipment to produce personalized products at scale. Integrating smart manufacturing technologies facilitates flexibility and efficiency, meeting diverse customer demands while maintaining cost-effectiveness.

Key Terms

Flexibility

Mass customization offers unparalleled flexibility by allowing production to adapt to individual customer preferences through modular designs and agile manufacturing processes. Lights out factories maximize operational efficiency and consistency by running fully automated systems without human intervention, but often compromise flexibility due to rigid process automation. Explore how balancing flexibility and automation can transform manufacturing strategies.

Automation

Mass customization leverages automation technologies to produce tailored products at scale, integrating flexible manufacturing systems with advanced robotics to meet individual customer demands efficiently. Lights-out factories utilize fully automated, unmanned production processes where machines operate continuously without human intervention, maximizing efficiency and reducing labor costs. Explore the specific automation strategies driving these manufacturing approaches to understand their operational advantages.

Scalability

Mass customization enables scalability by allowing products to be tailored to individual customer preferences while maintaining efficient production processes through flexible manufacturing systems. Lights out factories maximize scalability by operating fully automated production lines with minimal human intervention, resulting in continuous, high-volume output and reduced labor costs. Explore how integrating these approaches can optimize scalability in modern manufacturing.

Source and External Links

Mass Customization: A Complete Guide - Deskera - Mass customization is a business strategy that enables companies to deliver personalized products and services to customers cost-effectively by leveraging technology, automation, and scalable systems.

Guide to Mass Customization - Formlabs - Mass customization blends the individuality of custom-made products with the efficiency of mass production, using approaches like collaborative customization (co-creation with customers) and adaptive customization (products users can modify themselves).

Mass customization - Wikipedia - Mass customization uses flexible, computer-aided systems to produce individually tailored goods and services at near mass production costs, balancing high variety with operational efficiency.

dowidth.com

dowidth.com