Circular manufacturing emphasizes resource efficiency and sustainability by designing products for reuse, remanufacturing, and recycling, minimizing waste throughout the production cycle. Mass production focuses on large-scale manufacturing of standardized products to achieve economies of scale, often leading to increased resource consumption and environmental impact. Explore how circular manufacturing can transform traditional mass production models for a more sustainable future.

Why it is important

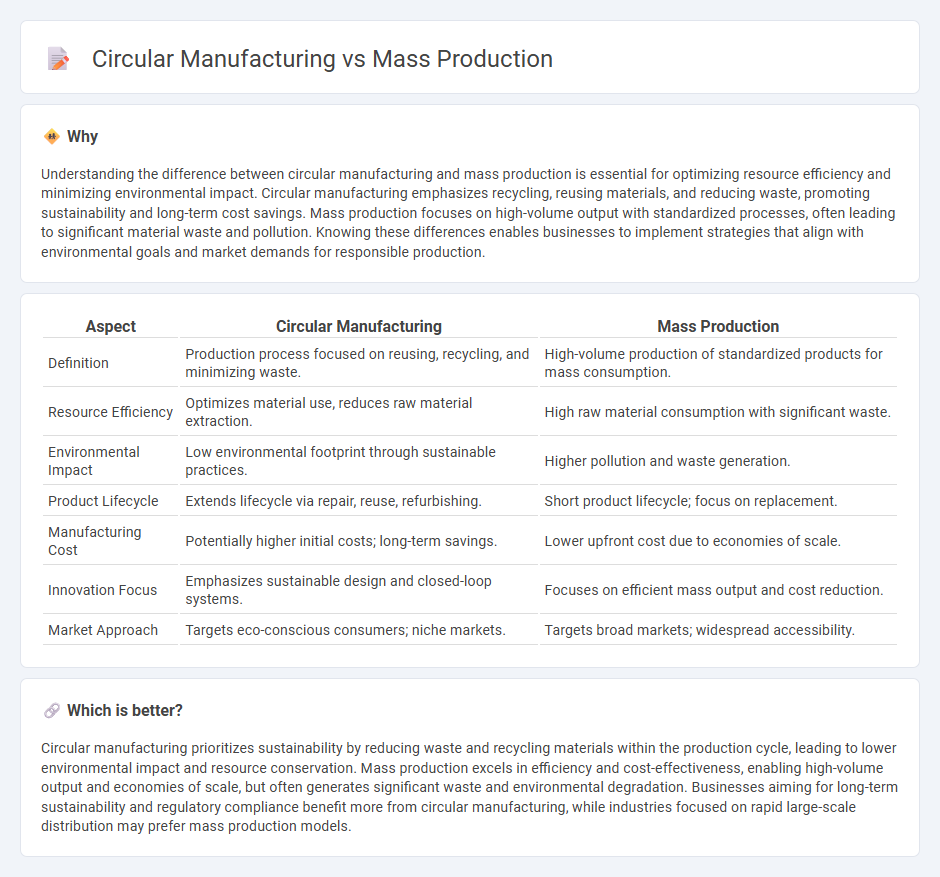

Understanding the difference between circular manufacturing and mass production is essential for optimizing resource efficiency and minimizing environmental impact. Circular manufacturing emphasizes recycling, reusing materials, and reducing waste, promoting sustainability and long-term cost savings. Mass production focuses on high-volume output with standardized processes, often leading to significant material waste and pollution. Knowing these differences enables businesses to implement strategies that align with environmental goals and market demands for responsible production.

Comparison Table

| Aspect | Circular Manufacturing | Mass Production |

|---|---|---|

| Definition | Production process focused on reusing, recycling, and minimizing waste. | High-volume production of standardized products for mass consumption. |

| Resource Efficiency | Optimizes material use, reduces raw material extraction. | High raw material consumption with significant waste. |

| Environmental Impact | Low environmental footprint through sustainable practices. | Higher pollution and waste generation. |

| Product Lifecycle | Extends lifecycle via repair, reuse, refurbishing. | Short product lifecycle; focus on replacement. |

| Manufacturing Cost | Potentially higher initial costs; long-term savings. | Lower upfront cost due to economies of scale. |

| Innovation Focus | Emphasizes sustainable design and closed-loop systems. | Focuses on efficient mass output and cost reduction. |

| Market Approach | Targets eco-conscious consumers; niche markets. | Targets broad markets; widespread accessibility. |

Which is better?

Circular manufacturing prioritizes sustainability by reducing waste and recycling materials within the production cycle, leading to lower environmental impact and resource conservation. Mass production excels in efficiency and cost-effectiveness, enabling high-volume output and economies of scale, but often generates significant waste and environmental degradation. Businesses aiming for long-term sustainability and regulatory compliance benefit more from circular manufacturing, while industries focused on rapid large-scale distribution may prefer mass production models.

Connection

Circular manufacturing integrates sustainable practices by recycling materials and minimizing waste during mass production processes. Mass production benefits from circular manufacturing through improved resource efficiency and reduced environmental impact. This synergy enhances product lifecycle management and supports a shift towards closed-loop industrial systems.

Key Terms

Scalability

Mass production emphasizes high scalability through standardized processes and economies of scale, enabling rapid output of uniform products. Circular manufacturing focuses on scalability by integrating resource-efficient practices, waste reduction, and product lifecycle extension to maintain sustainable growth. Explore how these scalability approaches impact industry transformation and environmental sustainability.

Resource Efficiency

Mass production typically consumes large quantities of raw materials and generates significant waste, resulting in low resource efficiency. Circular manufacturing emphasizes closed-loop systems that recycle materials and minimize waste, enhancing sustainability and reducing environmental impact. Explore how adopting circular manufacturing can improve resource efficiency and benefit both the economy and the planet.

Waste Management

Mass production typically generates substantial waste due to linear resource use and single-life product cycles, often leading to increased landfill and pollution. Circular manufacturing minimizes waste by designing for reuse, recycling, and resource regeneration, creating closed-loop systems that enhance sustainability. Explore how adopting circular manufacturing principles can revolutionize waste management and reduce environmental impact.

Source and External Links

What Is Mass Production? A Comprehensive Guide - Mass production is a highly organized manufacturing process designed to produce large quantities of standardized products using specialization, mechanization, economies of scale, and division of labor for maximum efficiency and consistency.

Mass production - Mass production involves making many copies of products rapidly through assembly lines, emphasizing automation and mechanization, which reduces labor needs and costs but requires significant capital investment in machinery.

Mass Production - Overview, How It Works, Advantages - Mass production uses continuous flow or assembly lines to manufacture standardized product lines for extended periods, relying on labor division, mechanization, automation, and quality control to produce uniform products at low cost.

dowidth.com

dowidth.com