Automated guided vehicles (AGVs) offer flexible, programmable transport solutions that can navigate complex factory layouts without the need for fixed infrastructure, enhancing efficiency in material handling. Conveyor systems provide continuous, high-speed movement of goods along predetermined paths, ideal for streamlined production lines with consistent workflows. Discover the advantages and applications of each system to optimize your manufacturing operations.

Why it is important

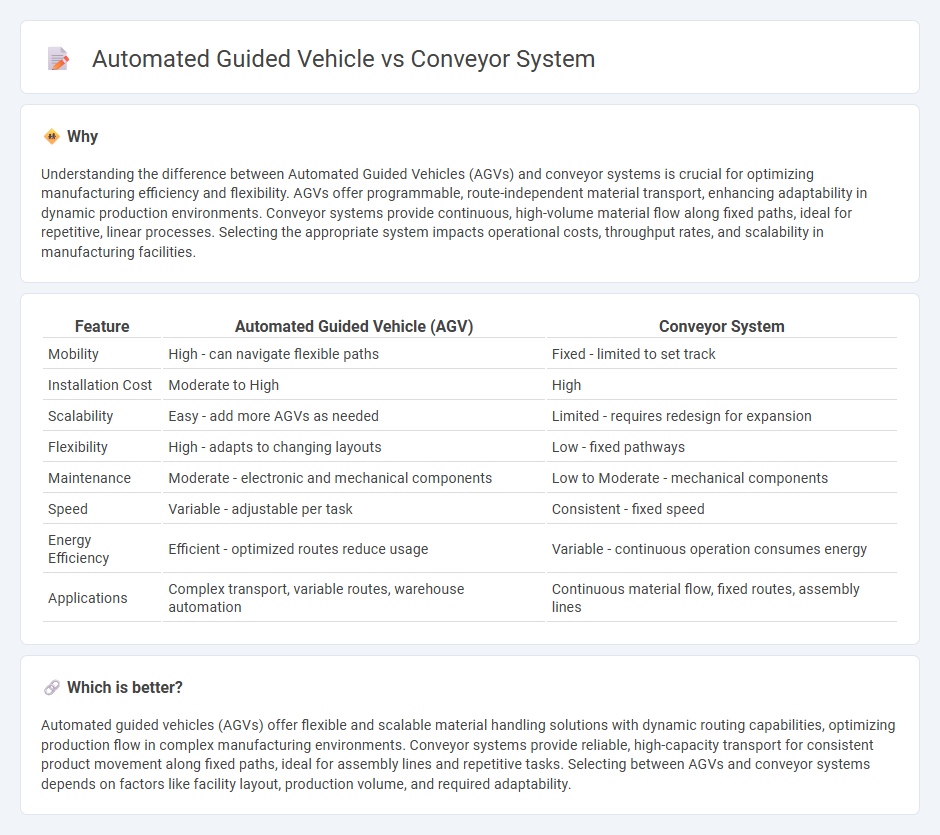

Understanding the difference between Automated Guided Vehicles (AGVs) and conveyor systems is crucial for optimizing manufacturing efficiency and flexibility. AGVs offer programmable, route-independent material transport, enhancing adaptability in dynamic production environments. Conveyor systems provide continuous, high-volume material flow along fixed paths, ideal for repetitive, linear processes. Selecting the appropriate system impacts operational costs, throughput rates, and scalability in manufacturing facilities.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Conveyor System |

|---|---|---|

| Mobility | High - can navigate flexible paths | Fixed - limited to set track |

| Installation Cost | Moderate to High | High |

| Scalability | Easy - add more AGVs as needed | Limited - requires redesign for expansion |

| Flexibility | High - adapts to changing layouts | Low - fixed pathways |

| Maintenance | Moderate - electronic and mechanical components | Low to Moderate - mechanical components |

| Speed | Variable - adjustable per task | Consistent - fixed speed |

| Energy Efficiency | Efficient - optimized routes reduce usage | Variable - continuous operation consumes energy |

| Applications | Complex transport, variable routes, warehouse automation | Continuous material flow, fixed routes, assembly lines |

Which is better?

Automated guided vehicles (AGVs) offer flexible and scalable material handling solutions with dynamic routing capabilities, optimizing production flow in complex manufacturing environments. Conveyor systems provide reliable, high-capacity transport for consistent product movement along fixed paths, ideal for assembly lines and repetitive tasks. Selecting between AGVs and conveyor systems depends on factors like facility layout, production volume, and required adaptability.

Connection

Automated guided vehicles (AGVs) and conveyor systems are interconnected through integrated control software that synchronizes material flow in manufacturing environments. This connection enables seamless transfer of goods between stationary conveyors and mobile AGVs, optimizing production line efficiency and reducing manual handling. Real-time data exchange between AGVs and conveyors allows dynamic route adjustments based on workload and inventory demands.

Key Terms

**Conveyor system:**

Conveyor systems offer continuous, high-speed material handling ideal for fixed-path transportation in manufacturing and warehousing environments, reducing manual labor and increasing efficiency. They effectively handle heavy loads with minimal maintenance and provide consistent throughput, making them suitable for assembly lines and packaging processes. Explore more about optimizing your logistics with advanced conveyor solutions.

Belt

Belt conveyor systems provide continuous, reliable transportation of materials with a fixed path, ideal for high-volume, repetitive movement in manufacturing and packaging industries. Automated guided vehicles (AGVs) offer flexible routing and can navigate complex layouts, but their efficiency depends on battery life and navigation technology. Explore detailed comparisons to determine the best solution for your material handling needs.

Rollers

Conveyor systems with rollers offer continuous, high-capacity material handling ideal for straight-line transport of goods, reducing manual labor and improving operational efficiency. Automated guided vehicles (AGVs) excel in flexible navigation and dynamic routing within warehouses but generally carry smaller loads and require integration with floor space. Explore deeper insights into roller-based conveyors and AGV applications to optimize your material handling strategy.

Source and External Links

Conveyor Systems: Definition, Types, Design, and Uses - A conveyor system is a fast and efficient mechanical handling apparatus that moves materials automatically using belts, wheels, rollers, or chains, minimizing human error and labor costs while improving safety and handling heavy items efficiently.

Conveyor system - Wikipedia - Conveyor systems include various types such as vertical conveyors, which transport materials between different levels, often integrating with horizontal conveyors to form comprehensive material handling lines.

Conveyor Systems & Equipment - Bastian Solutions - Conveyor systems automate processes like transporting, sorting, and palletizing, tailored to specific needs to increase throughput, reduce bottlenecks, and maximize labor productivity in warehouses and production facilities.

dowidth.com

dowidth.com