Cobots, or collaborative robots, are designed to work safely alongside human operators, enhancing flexibility and efficiency in manufacturing processes, while industrial robots typically operate independently within fixed, controlled environments for high-volume, repetitive tasks. Cobots offer easier programming and adaptability, making them ideal for small to medium-sized enterprises, whereas industrial robots excel in precision and speed for mass production. Discover how integrating cobots and industrial robots can optimize your manufacturing operations.

Why it is important

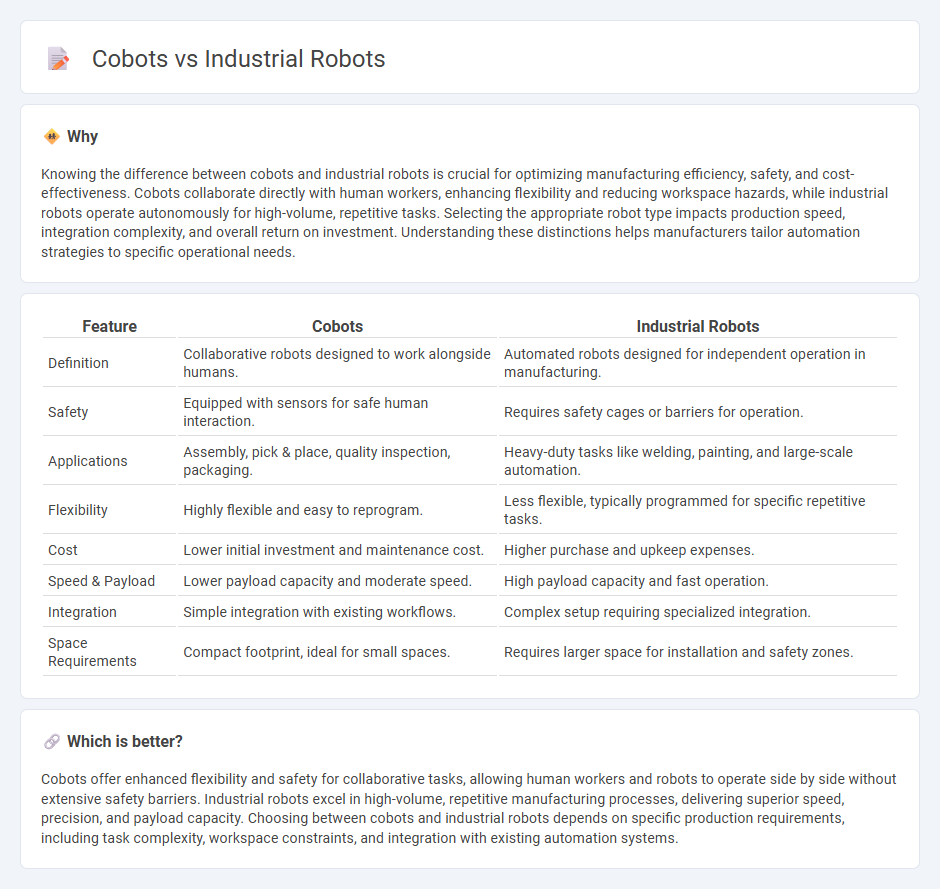

Knowing the difference between cobots and industrial robots is crucial for optimizing manufacturing efficiency, safety, and cost-effectiveness. Cobots collaborate directly with human workers, enhancing flexibility and reducing workspace hazards, while industrial robots operate autonomously for high-volume, repetitive tasks. Selecting the appropriate robot type impacts production speed, integration complexity, and overall return on investment. Understanding these distinctions helps manufacturers tailor automation strategies to specific operational needs.

Comparison Table

| Feature | Cobots | Industrial Robots |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans. | Automated robots designed for independent operation in manufacturing. |

| Safety | Equipped with sensors for safe human interaction. | Requires safety cages or barriers for operation. |

| Applications | Assembly, pick & place, quality inspection, packaging. | Heavy-duty tasks like welding, painting, and large-scale automation. |

| Flexibility | Highly flexible and easy to reprogram. | Less flexible, typically programmed for specific repetitive tasks. |

| Cost | Lower initial investment and maintenance cost. | Higher purchase and upkeep expenses. |

| Speed & Payload | Lower payload capacity and moderate speed. | High payload capacity and fast operation. |

| Integration | Simple integration with existing workflows. | Complex setup requiring specialized integration. |

| Space Requirements | Compact footprint, ideal for small spaces. | Requires larger space for installation and safety zones. |

Which is better?

Cobots offer enhanced flexibility and safety for collaborative tasks, allowing human workers and robots to operate side by side without extensive safety barriers. Industrial robots excel in high-volume, repetitive manufacturing processes, delivering superior speed, precision, and payload capacity. Choosing between cobots and industrial robots depends on specific production requirements, including task complexity, workspace constraints, and integration with existing automation systems.

Connection

Cobots and industrial robots are connected through their shared use of advanced automation technologies and sensors to perform precise manufacturing tasks. Cobots, designed for collaborative work alongside human operators, complement industrial robots by enhancing flexibility and safety on production lines. Integration of IoT systems enables synchronized operation and real-time data exchange between cobots and industrial robots, optimizing overall manufacturing efficiency.

Key Terms

Automation

Industrial robots excel in high-volume, repetitive tasks with precision and speed, often operating in isolated environments to ensure safety. Cobots, or collaborative robots, are designed to work alongside human operators, enhancing flexibility and productivity in dynamic workflows without extensive safety barriers. Explore the advantages of automation with both industrial robots and cobots to optimize your manufacturing processes.

Human-robot collaboration

Industrial robots operate independently, performing repetitive tasks with high precision and speed in controlled environments, while cobots are designed to work safely alongside humans, enhancing collaboration through advanced sensors and adaptive control systems. Cobots allow for flexible task sharing and real-time adjustments, improving efficiency and workplace safety in mixed human-robot settings. Explore the latest advancements in human-robot collaboration to better understand the impact of cobots on modern manufacturing.

Safety systems

Industrial robots rely heavily on physical barriers, such as safety fences and light curtains, to prevent human access during operation, ensuring strict separation for hazard control. Cobots integrate advanced sensor technologies and real-time monitoring systems that allow safe, direct human-robot interaction without extensive protective enclosures. Explore the latest safety innovations to understand how smart systems are revolutionizing collaborative and traditional robotic applications.

Source and External Links

What Are Industrial Robots? - Industrial robots are automated machines primarily used in manufacturing for tasks like assembly and material handling, equipped with at least one reprogrammable robotic arm that operates on three or more axes and designed for speed, strength, and precision in repetitive or dangerous operations in factories and warehouses.

The IFR's use of the term "industrial robot" is based ... - The International Federation of Robotics highlights how industrial robots are increasingly connected within smart automation strategies that optimize production processes, machine performance, and enable real-time sensing and response, helping manufacturers avoid costly downtime and improve flexibility.

Industrial robot - Industrial robots are programmable, automated robot systems capable of movement on three or more axes widely applied in tasks such as welding, painting, assembly, packaging, and product inspection, with over 4.2 million units estimated worldwide in 2023.

dowidth.com

dowidth.com