Biofabrication utilizes living cells and biomaterials to create complex tissue structures through techniques like 3D bioprinting, enabling advancements in regenerative medicine and personalized implants. Lithography employs light or electron beams to pattern substrates at micro- and nanoscale, driving innovations in semiconductor manufacturing and microelectromechanical systems (MEMS). Explore the distinct applications and benefits of biofabrication and lithography in modern manufacturing.

Why it is important

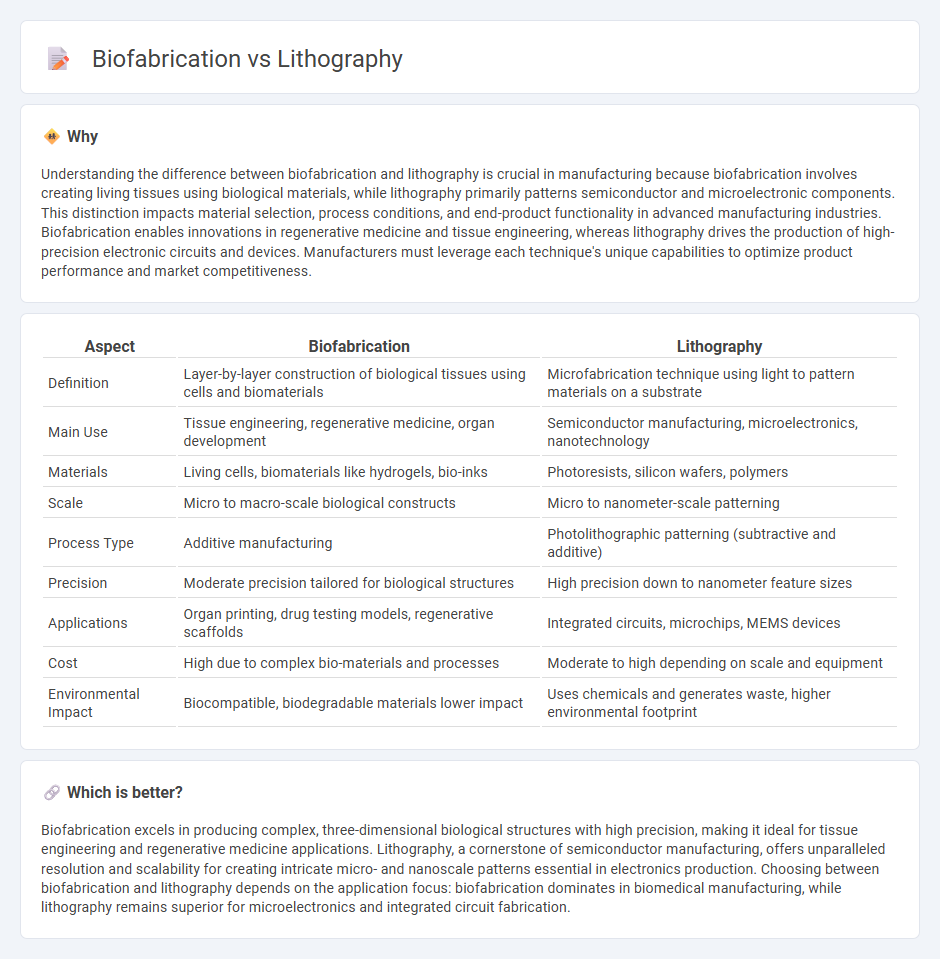

Understanding the difference between biofabrication and lithography is crucial in manufacturing because biofabrication involves creating living tissues using biological materials, while lithography primarily patterns semiconductor and microelectronic components. This distinction impacts material selection, process conditions, and end-product functionality in advanced manufacturing industries. Biofabrication enables innovations in regenerative medicine and tissue engineering, whereas lithography drives the production of high-precision electronic circuits and devices. Manufacturers must leverage each technique's unique capabilities to optimize product performance and market competitiveness.

Comparison Table

| Aspect | Biofabrication | Lithography |

|---|---|---|

| Definition | Layer-by-layer construction of biological tissues using cells and biomaterials | Microfabrication technique using light to pattern materials on a substrate |

| Main Use | Tissue engineering, regenerative medicine, organ development | Semiconductor manufacturing, microelectronics, nanotechnology |

| Materials | Living cells, biomaterials like hydrogels, bio-inks | Photoresists, silicon wafers, polymers |

| Scale | Micro to macro-scale biological constructs | Micro to nanometer-scale patterning |

| Process Type | Additive manufacturing | Photolithographic patterning (subtractive and additive) |

| Precision | Moderate precision tailored for biological structures | High precision down to nanometer feature sizes |

| Applications | Organ printing, drug testing models, regenerative scaffolds | Integrated circuits, microchips, MEMS devices |

| Cost | High due to complex bio-materials and processes | Moderate to high depending on scale and equipment |

| Environmental Impact | Biocompatible, biodegradable materials lower impact | Uses chemicals and generates waste, higher environmental footprint |

Which is better?

Biofabrication excels in producing complex, three-dimensional biological structures with high precision, making it ideal for tissue engineering and regenerative medicine applications. Lithography, a cornerstone of semiconductor manufacturing, offers unparalleled resolution and scalability for creating intricate micro- and nanoscale patterns essential in electronics production. Choosing between biofabrication and lithography depends on the application focus: biofabrication dominates in biomedical manufacturing, while lithography remains superior for microelectronics and integrated circuit fabrication.

Connection

Biofabrication integrates lithography techniques to precisely pattern biomaterials at micro and nanoscale levels, enabling the creation of complex tissue scaffolds and medical implants. Lithography provides high-resolution spatial control crucial for constructing cellular architectures in biofabrication processes. This synergy enhances manufacturing innovation in regenerative medicine and biomedical engineering.

Key Terms

Photolithography

Photolithography employs light to transfer geometric patterns onto substrates, enabling high-resolution microfabrication essential for semiconductor manufacturing and microelectromechanical systems (MEMS). Unlike biofabrication, which constructs biological structures using living cells, photolithography excels in creating precise, inorganic microstructures with microscale accuracy. Explore detailed comparisons to understand how photolithography drives innovation in microfabrication and its applications in biomedical engineering.

Bioprinting

Bioprinting integrates lithography precision with biofabrication's biological complexity, enabling the construction of intricate tissue structures layer by layer using biomaterials and living cells. This technology enhances tissue engineering applications by allowing for high-resolution spatial control of cell placement, vital for replicating native tissue architecture. Explore further to understand how state-of-the-art bioprinting techniques are revolutionizing regenerative medicine and personalized healthcare.

Resolution

Lithography techniques achieve ultrahigh resolution patterns down to the nanometer scale, enabling precise micro- and nanoscale structuring ideal for semiconductor and microfluidic applications. Biofabrication methods, while advancing rapidly, typically offer lower resolution, often limited to tens of micrometers due to material properties and biological compatibility constraints. Explore the latest developments comparing lithography and biofabrication resolution capabilities to better understand their specific applications and trade-offs.

Source and External Links

Lithograph | The Metropolitan Museum of Art - Provides an overview of lithography as a planographic printmaking process using a flat stone or metal plate.

Lithography - Wikipedia - Describes lithography as a printing method that utilizes the immiscibility of oil and water to create images on stone or metal plates.

Lithography: It's a Process | Columbia Museum of Art - Explains the basics of lithography, including its use of oil-based mediums on stone substrates for printmaking.

dowidth.com

dowidth.com