Digital thread integrates data across the entire product lifecycle, linking design, manufacturing, and supply chain processes into a continuous information flow. MES (Manufacturing Execution System) focuses on real-time production monitoring and control, optimizing shop floor operations and ensuring quality and compliance. Explore how combining digital thread and MES can revolutionize manufacturing efficiency and traceability.

Why it is important

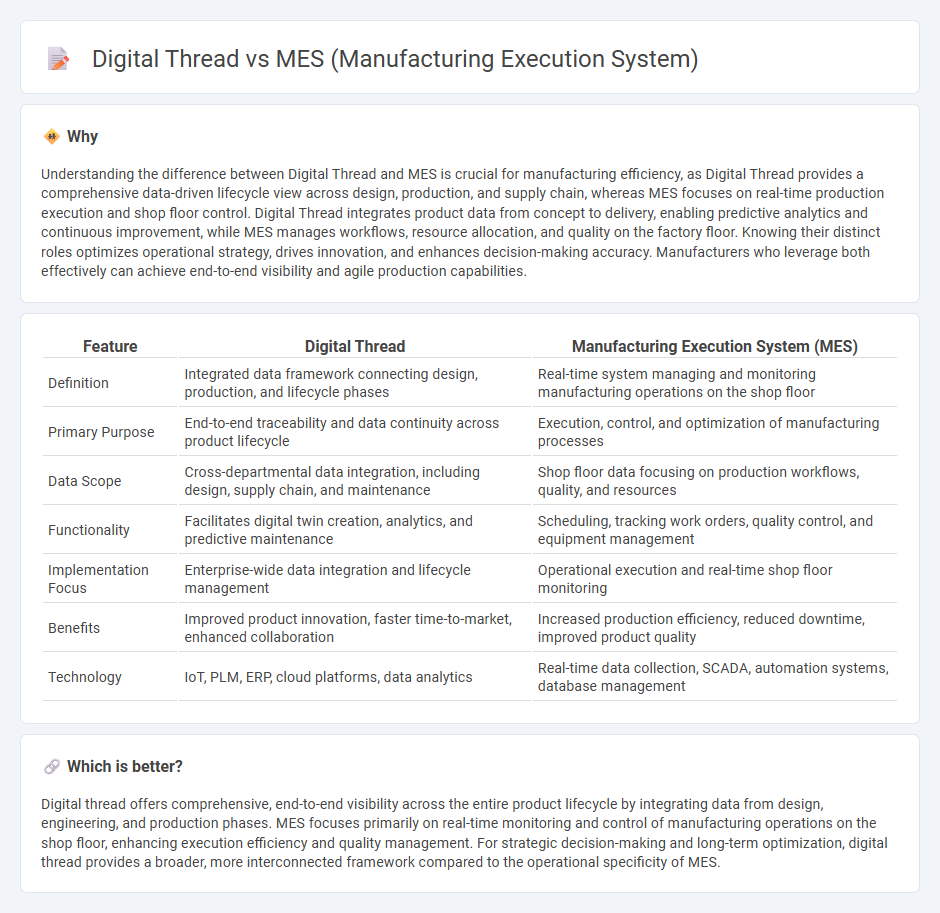

Understanding the difference between Digital Thread and MES is crucial for manufacturing efficiency, as Digital Thread provides a comprehensive data-driven lifecycle view across design, production, and supply chain, whereas MES focuses on real-time production execution and shop floor control. Digital Thread integrates product data from concept to delivery, enabling predictive analytics and continuous improvement, while MES manages workflows, resource allocation, and quality on the factory floor. Knowing their distinct roles optimizes operational strategy, drives innovation, and enhances decision-making accuracy. Manufacturers who leverage both effectively can achieve end-to-end visibility and agile production capabilities.

Comparison Table

| Feature | Digital Thread | Manufacturing Execution System (MES) |

|---|---|---|

| Definition | Integrated data framework connecting design, production, and lifecycle phases | Real-time system managing and monitoring manufacturing operations on the shop floor |

| Primary Purpose | End-to-end traceability and data continuity across product lifecycle | Execution, control, and optimization of manufacturing processes |

| Data Scope | Cross-departmental data integration, including design, supply chain, and maintenance | Shop floor data focusing on production workflows, quality, and resources |

| Functionality | Facilitates digital twin creation, analytics, and predictive maintenance | Scheduling, tracking work orders, quality control, and equipment management |

| Implementation Focus | Enterprise-wide data integration and lifecycle management | Operational execution and real-time shop floor monitoring |

| Benefits | Improved product innovation, faster time-to-market, enhanced collaboration | Increased production efficiency, reduced downtime, improved product quality |

| Technology | IoT, PLM, ERP, cloud platforms, data analytics | Real-time data collection, SCADA, automation systems, database management |

Which is better?

Digital thread offers comprehensive, end-to-end visibility across the entire product lifecycle by integrating data from design, engineering, and production phases. MES focuses primarily on real-time monitoring and control of manufacturing operations on the shop floor, enhancing execution efficiency and quality management. For strategic decision-making and long-term optimization, digital thread provides a broader, more interconnected framework compared to the operational specificity of MES.

Connection

The digital thread integrates real-time data from the Manufacturing Execution System (MES) to create a seamless flow of information across the production lifecycle, enhancing traceability and process optimization. MES serves as a critical data source within the digital thread, enabling detailed tracking of production operations, quality control, and resource management. This connection drives improved decision-making, reduces operational inefficiencies, and supports smart manufacturing initiatives.

Key Terms

Real-time Production Monitoring

MES (Manufacturing Execution System) enables real-time production monitoring by capturing and analyzing data directly from the factory floor, facilitating immediate decision-making and process optimization. The Digital Thread connects MES data with design, supply chain, and quality systems to create a comprehensive, traceable flow of information across the entire product lifecycle. Discover how integrating MES and the Digital Thread can revolutionize real-time production monitoring capabilities.

Data Integration

MES (Manufacturing Execution System) centralizes real-time shop floor data to optimize production processes, quality control, and resource management. Digital thread extends beyond MES by integrating data across the entire product lifecycle, linking design, engineering, manufacturing, and service information into a unified framework. Explore how combining MES with a digital thread enhances comprehensive data integration and drives smarter manufacturing decisions.

End-to-End Traceability

Manufacturing Execution Systems (MES) provide real-time data capture and control on the factory floor, ensuring operational efficiency and localized traceability of production processes. The digital thread extends traceability by integrating data across the entire product lifecycle--from design and manufacturing to service--enabling seamless end-to-end visibility and informed decision-making. Explore how combining MES with digital thread strategies enhances comprehensive traceability and drives manufacturing excellence.

Source and External Links

Manufacturing execution system - MES (Manufacturing Execution System) is a computerized system that tracks and documents the transformation of raw materials to finished goods, providing real-time monitoring and control of production resources, processes, and quality, acting as a bridge between ERP systems and plant floor operations to boost production efficiency.

What is a Manufacturing Execution System (MES)? - MES is a software solution used to monitor and control manufacturing production processes on the shop floor, enabling real-time data capture, production visibility, quality assurance, inventory control, and optimized decision-making for higher operational effectiveness.

Top 10 benefits of Manufacturing Execution Systems (MES) - MES integrates production equipment with business systems, enforces quality and process controls, collects and stores operational data, supports traceability, and drives smart manufacturing digital transformation by enhancing productivity and responsiveness across production, quality, and maintenance.

dowidth.com

dowidth.com