Cobotics integrates collaborative robots into manufacturing processes to enhance precision, flexibility, and worker safety, contrasting with just-in-time (JIT) production, which focuses on minimizing inventory and reducing waste through precise timing. While cobotics enables automation alongside human labor for increased efficiency, JIT streamlines the supply chain to align production schedules closely with demand. Explore how combining cobotics with JIT strategies can revolutionize modern manufacturing workflows.

Why it is important

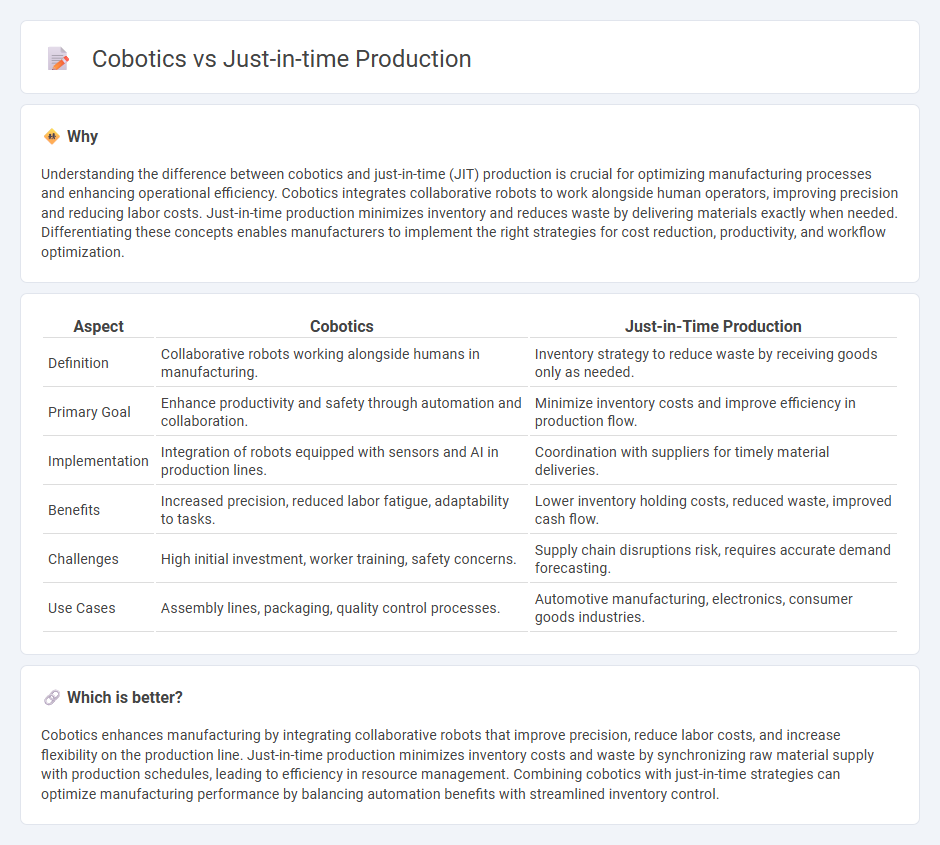

Understanding the difference between cobotics and just-in-time (JIT) production is crucial for optimizing manufacturing processes and enhancing operational efficiency. Cobotics integrates collaborative robots to work alongside human operators, improving precision and reducing labor costs. Just-in-time production minimizes inventory and reduces waste by delivering materials exactly when needed. Differentiating these concepts enables manufacturers to implement the right strategies for cost reduction, productivity, and workflow optimization.

Comparison Table

| Aspect | Cobotics | Just-in-Time Production |

|---|---|---|

| Definition | Collaborative robots working alongside humans in manufacturing. | Inventory strategy to reduce waste by receiving goods only as needed. |

| Primary Goal | Enhance productivity and safety through automation and collaboration. | Minimize inventory costs and improve efficiency in production flow. |

| Implementation | Integration of robots equipped with sensors and AI in production lines. | Coordination with suppliers for timely material deliveries. |

| Benefits | Increased precision, reduced labor fatigue, adaptability to tasks. | Lower inventory holding costs, reduced waste, improved cash flow. |

| Challenges | High initial investment, worker training, safety concerns. | Supply chain disruptions risk, requires accurate demand forecasting. |

| Use Cases | Assembly lines, packaging, quality control processes. | Automotive manufacturing, electronics, consumer goods industries. |

Which is better?

Cobotics enhances manufacturing by integrating collaborative robots that improve precision, reduce labor costs, and increase flexibility on the production line. Just-in-time production minimizes inventory costs and waste by synchronizing raw material supply with production schedules, leading to efficiency in resource management. Combining cobotics with just-in-time strategies can optimize manufacturing performance by balancing automation benefits with streamlined inventory control.

Connection

Cobotics enhances just-in-time production by enabling flexible, real-time collaboration between humans and robots, which reduces downtime and increases efficiency on the manufacturing floor. Just-in-time production relies on precise timing and minimal inventory, and cobots provide adaptive automation that adjusts to varying workloads without disrupting the supply chain. The integration of cobotic systems streamlines workflows, improves quality control, and accelerates response times, directly supporting the lean inventory principles central to just-in-time manufacturing.

Key Terms

Inventory management

Just-in-time (JIT) production minimizes inventory levels by synchronizing raw material orders with production schedules, reducing holding costs and waste. Cobotics enhances inventory management through collaborative robots that improve accuracy in tracking, sorting, and replenishing stock in real-time. Discover how integrating JIT principles with cobotic technologies can revolutionize your inventory efficiency.

Human-robot collaboration

Just-in-time production enhances efficiency by minimizing inventory and synchronizing materials with demand, while cobotics advances human-robot collaboration through shared workspaces and cooperative tasks, improving flexibility and productivity. Integrating cobotics within just-in-time systems reduces downtime and streamlines operations by combining robotic precision with human adaptability. Discover how optimizing human-robot collaboration can revolutionize manufacturing workflows.

Workflow optimization

Just-in-time production minimizes inventory and reduces waste by synchronizing manufacturing schedules with demand, enhancing supply chain efficiency. Cobotics integrates collaborative robots into workflows to automate repetitive tasks, thereby increasing precision and flexibility on the production floor. Explore the synergy between just-in-time strategies and cobotic systems to unlock advanced workflow optimization insights.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time manufacturing is a production strategy where goods are made only as needed, reducing inventory costs, improving efficiency, and minimizing waste by aligning production with customer demand.

Lean manufacturing - Just-in-time manufacturing matches production to demand by supplying only ordered goods, using methods like setup reduction, lot sizes of one, and pull systems (kanban) to increase efficiency and flexibility.

What is just-in-time manufacturing (JIT ... - Just-in-time manufacturing is a model in which items are produced strictly to meet actual demand, eliminating surpluses and aiming to cut costs and shorten delivery times by removing overproduction and excess inventory.

dowidth.com

dowidth.com