The Industrial Internet focuses on connecting machines, sensors, and devices through the Internet of Things (IoT) to optimize manufacturing processes with real-time data analytics. Industry 4.0 represents a broader paradigm integrating cyber-physical systems, automation, and smart technologies to create fully intelligent and flexible factories. Explore how these converging concepts are transforming manufacturing efficiency and innovation.

Why it is important

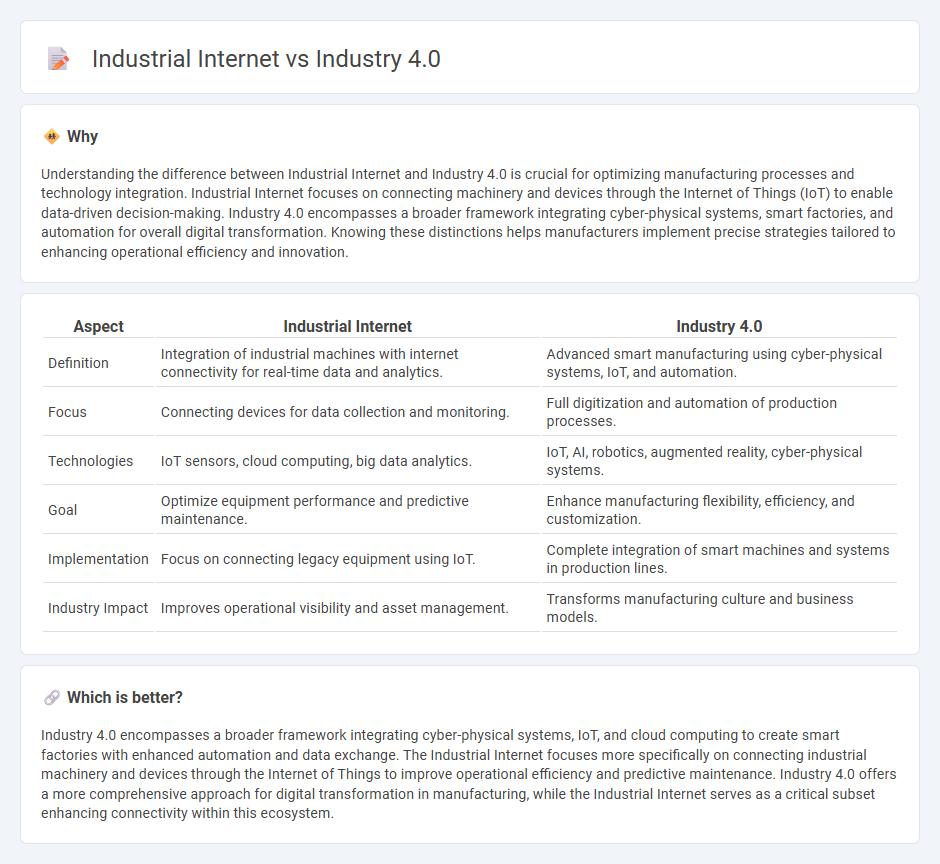

Understanding the difference between Industrial Internet and Industry 4.0 is crucial for optimizing manufacturing processes and technology integration. Industrial Internet focuses on connecting machinery and devices through the Internet of Things (IoT) to enable data-driven decision-making. Industry 4.0 encompasses a broader framework integrating cyber-physical systems, smart factories, and automation for overall digital transformation. Knowing these distinctions helps manufacturers implement precise strategies tailored to enhancing operational efficiency and innovation.

Comparison Table

| Aspect | Industrial Internet | Industry 4.0 |

|---|---|---|

| Definition | Integration of industrial machines with internet connectivity for real-time data and analytics. | Advanced smart manufacturing using cyber-physical systems, IoT, and automation. |

| Focus | Connecting devices for data collection and monitoring. | Full digitization and automation of production processes. |

| Technologies | IoT sensors, cloud computing, big data analytics. | IoT, AI, robotics, augmented reality, cyber-physical systems. |

| Goal | Optimize equipment performance and predictive maintenance. | Enhance manufacturing flexibility, efficiency, and customization. |

| Implementation | Focus on connecting legacy equipment using IoT. | Complete integration of smart machines and systems in production lines. |

| Industry Impact | Improves operational visibility and asset management. | Transforms manufacturing culture and business models. |

Which is better?

Industry 4.0 encompasses a broader framework integrating cyber-physical systems, IoT, and cloud computing to create smart factories with enhanced automation and data exchange. The Industrial Internet focuses more specifically on connecting industrial machinery and devices through the Internet of Things to improve operational efficiency and predictive maintenance. Industry 4.0 offers a more comprehensive approach for digital transformation in manufacturing, while the Industrial Internet serves as a critical subset enhancing connectivity within this ecosystem.

Connection

The Industrial Internet integrates advanced sensor technologies and connectivity to enable real-time data exchange across manufacturing processes, driving efficiency and predictive maintenance. Industry 4.0 leverages these capabilities by combining cyber-physical systems, IoT devices, and big data analytics to create smart factories with autonomous decision-making. This synergy enhances production flexibility, reduces downtime, and optimizes resource management in modern manufacturing systems.

Key Terms

Cyber-Physical Systems

Cyber-Physical Systems (CPS) form the technological backbone of both Industry 4.0 and the Industrial Internet, enabling seamless integration between physical machinery and digital networks. Industry 4.0 emphasizes smart manufacturing through CPS by leveraging IoT, AI, and real-time data analytics for enhanced automation and operational intelligence. Explore deeper into how CPS transforms traditional industries by driving efficiency, predictive maintenance, and innovation.

Internet of Things (IoT)

Industry 4.0 integrates cyber-physical systems, IoT, and cloud computing to create smart factories with enhanced automation and data exchange. The Industrial Internet emphasizes connecting industrial assets through IoT sensors for real-time analytics and predictive maintenance across sectors like manufacturing and energy. Explore the key differences and applications of Industry 4.0 and the Industrial Internet to optimize your technology strategy.

Data Analytics

Industry 4.0 integrates advanced manufacturing technologies with data analytics to enhance automation, predictive maintenance, and real-time decision-making across smart factories. The Industrial Internet emphasizes connecting industrial machines and sensors to cloud-based platforms for large-scale data collection and analytics, enabling improved operational efficiency and asset management. Explore our comprehensive analysis to understand how these paradigms leverage data analytics for transforming industrial processes.

Source and External Links

Industry 4.0 vs 5.0: What's the Difference? - Rutgers University - Industry 4.0, known as the Fourth Industrial Revolution, is characterized by digital industrial technology and cyber-physical systems enabling smart, integrated factories through human-machine collaboration and data-driven manufacturing solutions since its launch in 2011.

What is Industry 4.0? - IBM - Industry 4.0 refers to the digital transformation of manufacturing that incorporates IoT, cloud computing, AI, and advanced sensors to create smart factories enabling real-time decision making, increased productivity, flexibility, and automation.

What are Industry 4.0, the Fourth Industrial Revolution, and 4IR? - McKinsey - Industry 4.0, the Fourth Industrial Revolution, is the era of connected digital systems, advanced analytics and automation transforming all industries--especially manufacturing, transportation, and retail--with varying adoption paths depending on existing technologies and infrastructure.

dowidth.com

dowidth.com