Process mining analyzes event logs to uncover inefficiencies in manufacturing workflows, enabling data-driven optimization of production steps. Digital Twin technology creates virtual replicas of manufacturing systems for real-time simulation, monitoring, and predictive maintenance. Explore deeper insights into how these technologies revolutionize manufacturing accuracy and efficiency.

Why it is important

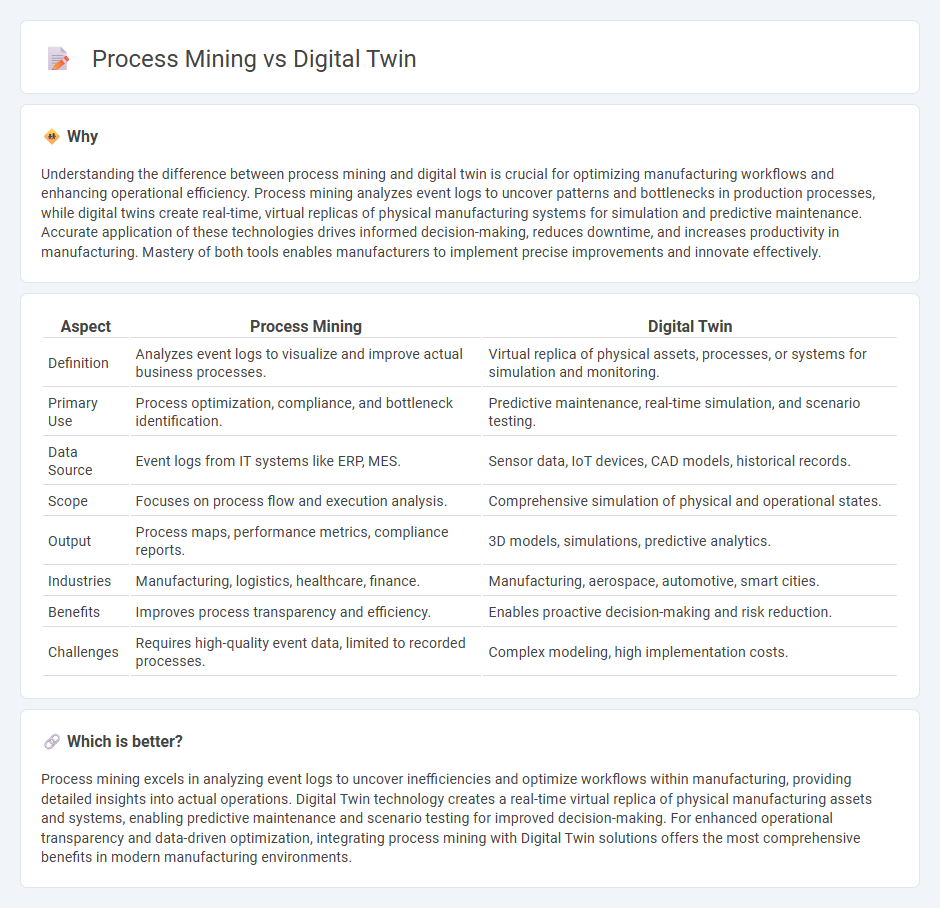

Understanding the difference between process mining and digital twin is crucial for optimizing manufacturing workflows and enhancing operational efficiency. Process mining analyzes event logs to uncover patterns and bottlenecks in production processes, while digital twins create real-time, virtual replicas of physical manufacturing systems for simulation and predictive maintenance. Accurate application of these technologies drives informed decision-making, reduces downtime, and increases productivity in manufacturing. Mastery of both tools enables manufacturers to implement precise improvements and innovate effectively.

Comparison Table

| Aspect | Process Mining | Digital Twin |

|---|---|---|

| Definition | Analyzes event logs to visualize and improve actual business processes. | Virtual replica of physical assets, processes, or systems for simulation and monitoring. |

| Primary Use | Process optimization, compliance, and bottleneck identification. | Predictive maintenance, real-time simulation, and scenario testing. |

| Data Source | Event logs from IT systems like ERP, MES. | Sensor data, IoT devices, CAD models, historical records. |

| Scope | Focuses on process flow and execution analysis. | Comprehensive simulation of physical and operational states. |

| Output | Process maps, performance metrics, compliance reports. | 3D models, simulations, predictive analytics. |

| Industries | Manufacturing, logistics, healthcare, finance. | Manufacturing, aerospace, automotive, smart cities. |

| Benefits | Improves process transparency and efficiency. | Enables proactive decision-making and risk reduction. |

| Challenges | Requires high-quality event data, limited to recorded processes. | Complex modeling, high implementation costs. |

Which is better?

Process mining excels in analyzing event logs to uncover inefficiencies and optimize workflows within manufacturing, providing detailed insights into actual operations. Digital Twin technology creates a real-time virtual replica of physical manufacturing assets and systems, enabling predictive maintenance and scenario testing for improved decision-making. For enhanced operational transparency and data-driven optimization, integrating process mining with Digital Twin solutions offers the most comprehensive benefits in modern manufacturing environments.

Connection

Process mining enhances manufacturing efficiency by analyzing event logs to identify bottlenecks and deviations in production workflows. Digital Twin technology creates a virtual replica of physical manufacturing systems, enabling real-time simulation and predictive maintenance based on process mining insights. Integrating process mining with Digital Twins allows manufacturers to optimize operations, improve asset utilization, and reduce downtime through data-driven decision-making.

Key Terms

Real-time Simulation

Digital Twin technology enables real-time simulation by creating a virtual replica of physical assets, processes, or systems to monitor and predict operational performance dynamically. Process mining leverages event logs from IT systems to uncover inefficiencies and optimize workflows based on historical and near real-time data patterns. Explore the differences and synergies between Digital Twin and process mining to enhance real-time simulation capabilities.

Event Log Analysis

Digital Twin technology creates real-time virtual models of physical systems, enabling simulation and optimization across various industries. Process mining concentrates on Event Log Analysis to discover, monitor, and improve business processes by extracting insights from event logs. Explore the detailed differences and applications to leverage these powerful tools effectively.

Predictive Maintenance

Digital Twin technology creates virtual replicas of physical assets to simulate real-time operations and predict equipment failures, enhancing predictive maintenance accuracy. Process mining analyzes event logs from IT systems to uncover process inefficiencies and deviations, supporting maintenance scheduling based on data-driven insights. Explore how integrating Digital Twin and process mining can revolutionize predictive maintenance strategies and operational efficiency.

Source and External Links

Definition of a Digital Twin - A digital twin is an integrated data-driven virtual representation of real-world entities and processes, with synchronized interaction at a specified frequency and fidelity, built on real-time and historical data to simulate, analyze, and improve real-world systems.

Digital twin - Wikipedia - A digital twin is a digital model of a physical product, system, or process that serves as a digital counterpart for simulation, testing, monitoring, and optimization throughout its lifecycle by continuously updating with real-world data.

What is Digital Twin and why is it important? - PTC - A digital twin is a virtual model of a physical item, process, or system that uses real-world data to understand, predict, and optimize its counterpart's performance, quality, and maintenance across engineering, manufacturing, and service.

dowidth.com

dowidth.com