Condition monitoring continuously collects data from machinery using sensors to detect early signs of wear or failure, enabling proactive maintenance and reducing downtime. Equipment diagnostics involves analyzing this data to identify the root causes of detected issues and recommend targeted repairs or adjustments. Explore advanced strategies in condition monitoring and equipment diagnostics to enhance manufacturing efficiency and asset reliability.

Why it is important

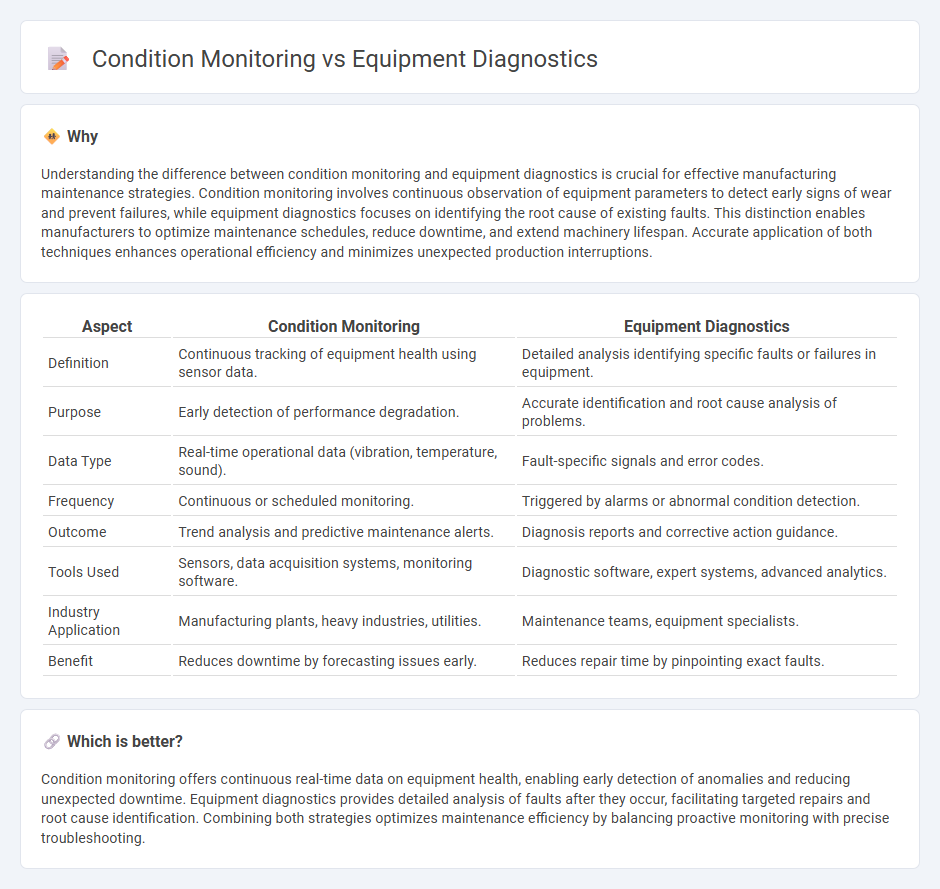

Understanding the difference between condition monitoring and equipment diagnostics is crucial for effective manufacturing maintenance strategies. Condition monitoring involves continuous observation of equipment parameters to detect early signs of wear and prevent failures, while equipment diagnostics focuses on identifying the root cause of existing faults. This distinction enables manufacturers to optimize maintenance schedules, reduce downtime, and extend machinery lifespan. Accurate application of both techniques enhances operational efficiency and minimizes unexpected production interruptions.

Comparison Table

| Aspect | Condition Monitoring | Equipment Diagnostics |

|---|---|---|

| Definition | Continuous tracking of equipment health using sensor data. | Detailed analysis identifying specific faults or failures in equipment. |

| Purpose | Early detection of performance degradation. | Accurate identification and root cause analysis of problems. |

| Data Type | Real-time operational data (vibration, temperature, sound). | Fault-specific signals and error codes. |

| Frequency | Continuous or scheduled monitoring. | Triggered by alarms or abnormal condition detection. |

| Outcome | Trend analysis and predictive maintenance alerts. | Diagnosis reports and corrective action guidance. |

| Tools Used | Sensors, data acquisition systems, monitoring software. | Diagnostic software, expert systems, advanced analytics. |

| Industry Application | Manufacturing plants, heavy industries, utilities. | Maintenance teams, equipment specialists. |

| Benefit | Reduces downtime by forecasting issues early. | Reduces repair time by pinpointing exact faults. |

Which is better?

Condition monitoring offers continuous real-time data on equipment health, enabling early detection of anomalies and reducing unexpected downtime. Equipment diagnostics provides detailed analysis of faults after they occur, facilitating targeted repairs and root cause identification. Combining both strategies optimizes maintenance efficiency by balancing proactive monitoring with precise troubleshooting.

Connection

Condition monitoring uses sensors and data analysis to continuously track equipment performance, enabling real-time detection of anomalies that signal potential failures. Equipment diagnostics processes this data to identify specific faults and determine their root causes, facilitating targeted maintenance actions. Together, they enhance manufacturing reliability by reducing unplanned downtime and optimizing asset management.

Key Terms

**Equipment diagnostics:**

Equipment diagnostics involves the detailed analysis and identification of faults or malfunctions within machinery using advanced tools like vibration analysis, thermal imaging, and ultrasonic testing. This approach provides precise data to pinpoint issues, enabling targeted repairs and minimizing downtime. Explore our insights to understand how equipment diagnostics can enhance maintenance strategies.

Fault detection

Equipment diagnostics involves identifying and analyzing faults in machinery to determine the root cause of failures, while condition monitoring continuously tracks equipment health through sensor data to detect early signs of potential issues. Fault detection is central to both processes, with diagnostics emphasizing detailed fault characterization and condition monitoring prioritizing real-time anomaly identification. Explore further to understand how these approaches enhance maintenance strategies and minimize downtime.

Root cause analysis

Equipment diagnostics involves identifying specific faults in machinery through detailed data analysis and sensor feedback, enabling precise troubleshooting of issues. Condition monitoring continuously tracks equipment health parameters such as vibration, temperature, and oil quality to detect deviations before failures occur, facilitating proactive maintenance strategies. Explore deeper insights into how root cause analysis integrates with both approaches to optimize machinery reliability and minimize downtime.

Source and External Links

Jaltest Construction Equipment Diagnostic Tools - Mechnician - Jaltest offers powerful diagnostic tools that provide dealer-level diagnostics for various construction equipment, allowing reading and clearing of fault codes, troubleshooting, and accessing repair instructions for efficient equipment repair and maintenance.

Jaltest Diagnostics - Jaltest Diagnostics is a comprehensive tool designed for all-makes and systems diagnostics across commercial vehicles, agricultural and construction equipment, offering advanced features, frequent updates, and customization for repair shops worldwide.

Basic Elements of Machinery Diagnostics: An Overview - enDAQ Blog - Machinery diagnostics involves analyzing machinery performance data using technical knowledge to detect faults reactively or proactively, helping maintain machine health and prevent failures by monitoring vibration and performance trends.

dowidth.com

dowidth.com