Mass customization combines the efficiency of mass production with the flexibility of individual customization, allowing manufacturers to produce tailored products at near mass-production speed. Cellular manufacturing organizes workstations into cells that focus on a specific product family, enhancing workflow and reducing lead times. Explore the advantages and application scenarios of both approaches to optimize your production strategy.

Why it is important

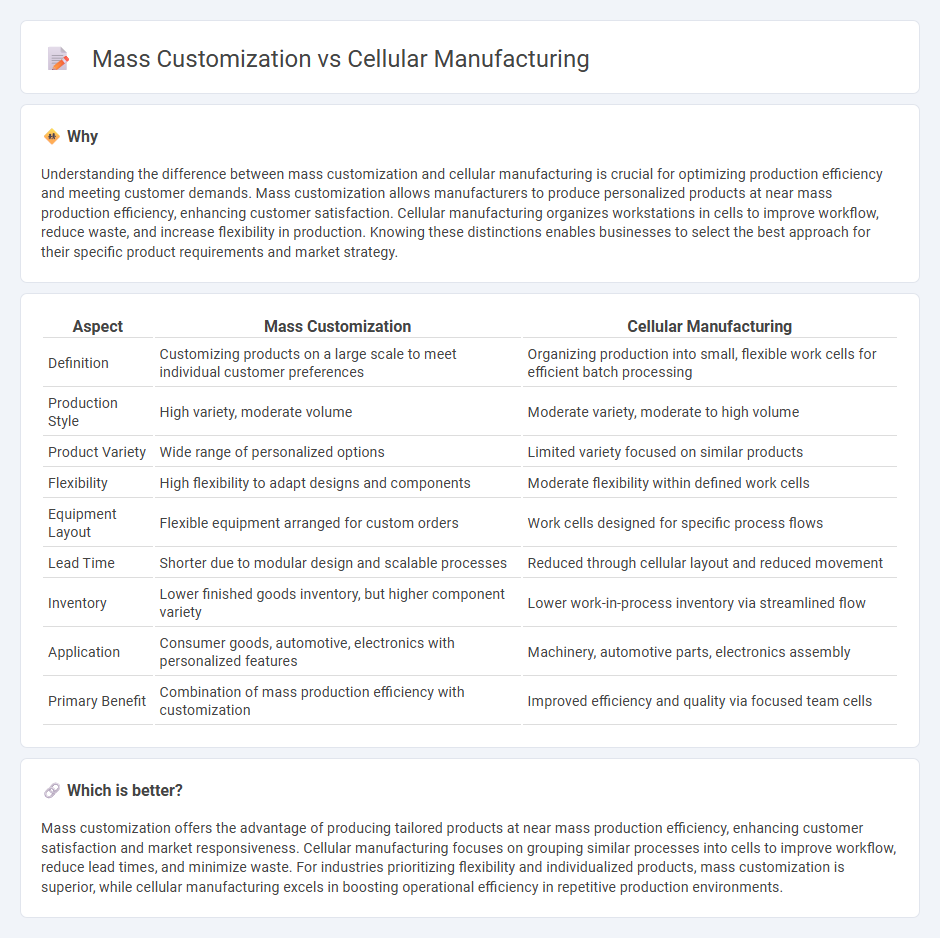

Understanding the difference between mass customization and cellular manufacturing is crucial for optimizing production efficiency and meeting customer demands. Mass customization allows manufacturers to produce personalized products at near mass production efficiency, enhancing customer satisfaction. Cellular manufacturing organizes workstations in cells to improve workflow, reduce waste, and increase flexibility in production. Knowing these distinctions enables businesses to select the best approach for their specific product requirements and market strategy.

Comparison Table

| Aspect | Mass Customization | Cellular Manufacturing |

|---|---|---|

| Definition | Customizing products on a large scale to meet individual customer preferences | Organizing production into small, flexible work cells for efficient batch processing |

| Production Style | High variety, moderate volume | Moderate variety, moderate to high volume |

| Product Variety | Wide range of personalized options | Limited variety focused on similar products |

| Flexibility | High flexibility to adapt designs and components | Moderate flexibility within defined work cells |

| Equipment Layout | Flexible equipment arranged for custom orders | Work cells designed for specific process flows |

| Lead Time | Shorter due to modular design and scalable processes | Reduced through cellular layout and reduced movement |

| Inventory | Lower finished goods inventory, but higher component variety | Lower work-in-process inventory via streamlined flow |

| Application | Consumer goods, automotive, electronics with personalized features | Machinery, automotive parts, electronics assembly |

| Primary Benefit | Combination of mass production efficiency with customization | Improved efficiency and quality via focused team cells |

Which is better?

Mass customization offers the advantage of producing tailored products at near mass production efficiency, enhancing customer satisfaction and market responsiveness. Cellular manufacturing focuses on grouping similar processes into cells to improve workflow, reduce lead times, and minimize waste. For industries prioritizing flexibility and individualized products, mass customization is superior, while cellular manufacturing excels in boosting operational efficiency in repetitive production environments.

Connection

Mass customization leverages cellular manufacturing to enhance production flexibility by organizing workstations into cells that focus on specific product variants. This approach reduces lead times and improves responsiveness to customer demands by enabling small-batch, personalized production runs within the same facility. Integrating cellular manufacturing principles streamlines workflow and supports efficient adaptation in mass customization environments.

Key Terms

Flexibility

Cellular manufacturing enhances flexibility by organizing workstations into cells to produce similar products efficiently, enabling quick changeovers and reducing lead times compared to traditional mass production methods. Mass customization leverages flexible production systems and advanced technologies to tailor products to individual customer preferences while maintaining large-scale production efficiency. Explore how these strategies can optimize your manufacturing flexibility and responsiveness.

Workflow

Cellular manufacturing organizes production into small, efficient work cells tailored for similar product families, enhancing workflow by minimizing movement and reducing setup times. Mass customization leverages flexible workflows and advanced technologies to produce personalized products at near mass production efficiency, integrating customer-specific modifications without disrupting overall throughput. Explore how these workflow strategies optimize production efficiency and meet diverse market demands.

Product Variety

Cellular manufacturing organizes production into small, flexible units designed for efficient handling of moderate product variety, enabling quicker changeovers and reduced waste. In contrast, mass customization leverages advanced technology and modular design to deliver a high degree of personalized product variety at near mass production efficiency. Explore further to understand how these approaches balance product variety and operational efficiency in modern manufacturing.

Source and External Links

Cellular Manufacturing: A Comprehensive Guide - Deskera - Cellular manufacturing is a production system that combines multiple processes into unified manufacturing cells designed to improve efficiency, involving assessment, cell design, process flow development, resource assignment, and performance monitoring.

Cellular manufacturing - Wikipedia - Cellular manufacturing uses multiple process "cells" arranged often in a U-shape, where each cell completes specific production steps to enable flexible, waste-reducing, and highly productive manufacturing under lean principles.

What Is Cellular Manufacturing? - MRPeasy - Cellular manufacturing organizes workstations and equipment into self-sufficient, cross-trained cells with layouts like U-shape or linear, improving communication, reducing waste, lead times, and space, applicable across industries such as automotive and electronics.

dowidth.com

dowidth.com