Mass customization blends the efficiency of mass production with personalized product variations tailored to individual customer preferences, leveraging flexible manufacturing systems and advanced technologies like CAD and robotics. Just-in-Time (JIT) production minimizes inventory costs by synchronizing manufacturing schedules closely with demand, ensuring materials arrive only as needed to reduce waste and improve cash flow. Explore how integrating mass customization and JIT strategies can revolutionize production processes and enhance competitive advantage.

Why it is important

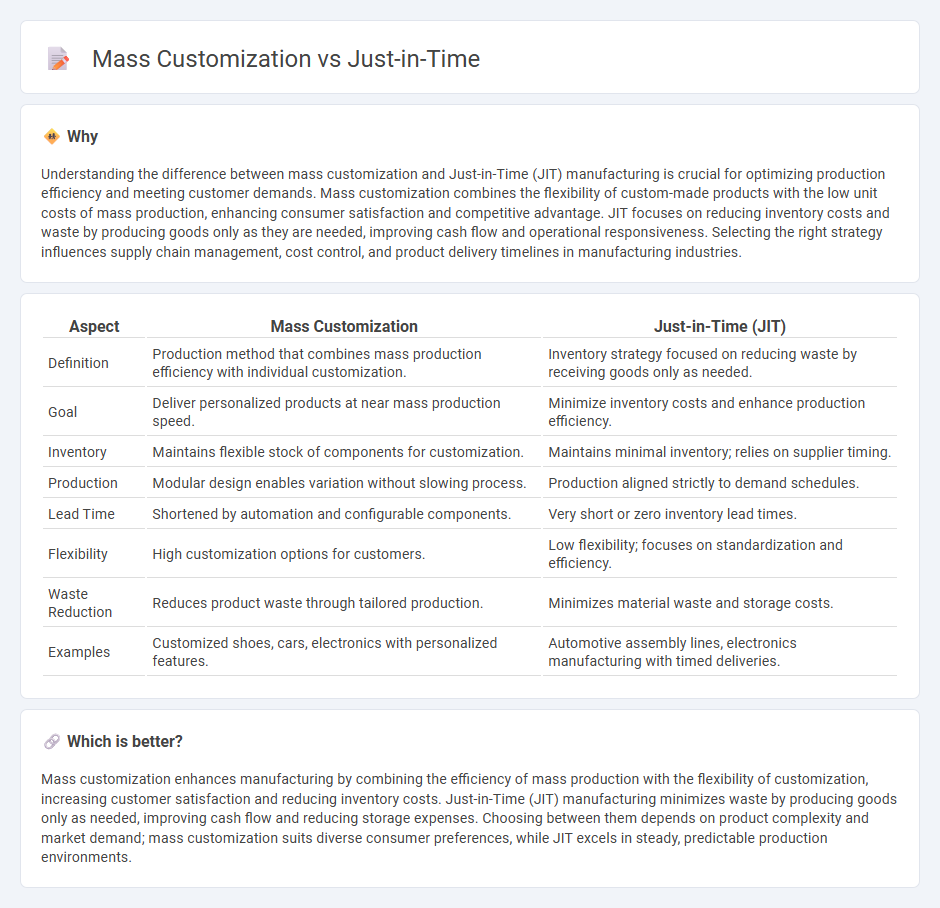

Understanding the difference between mass customization and Just-in-Time (JIT) manufacturing is crucial for optimizing production efficiency and meeting customer demands. Mass customization combines the flexibility of custom-made products with the low unit costs of mass production, enhancing consumer satisfaction and competitive advantage. JIT focuses on reducing inventory costs and waste by producing goods only as they are needed, improving cash flow and operational responsiveness. Selecting the right strategy influences supply chain management, cost control, and product delivery timelines in manufacturing industries.

Comparison Table

| Aspect | Mass Customization | Just-in-Time (JIT) |

|---|---|---|

| Definition | Production method that combines mass production efficiency with individual customization. | Inventory strategy focused on reducing waste by receiving goods only as needed. |

| Goal | Deliver personalized products at near mass production speed. | Minimize inventory costs and enhance production efficiency. |

| Inventory | Maintains flexible stock of components for customization. | Maintains minimal inventory; relies on supplier timing. |

| Production | Modular design enables variation without slowing process. | Production aligned strictly to demand schedules. |

| Lead Time | Shortened by automation and configurable components. | Very short or zero inventory lead times. |

| Flexibility | High customization options for customers. | Low flexibility; focuses on standardization and efficiency. |

| Waste Reduction | Reduces product waste through tailored production. | Minimizes material waste and storage costs. |

| Examples | Customized shoes, cars, electronics with personalized features. | Automotive assembly lines, electronics manufacturing with timed deliveries. |

Which is better?

Mass customization enhances manufacturing by combining the efficiency of mass production with the flexibility of customization, increasing customer satisfaction and reducing inventory costs. Just-in-Time (JIT) manufacturing minimizes waste by producing goods only as needed, improving cash flow and reducing storage expenses. Choosing between them depends on product complexity and market demand; mass customization suits diverse consumer preferences, while JIT excels in steady, predictable production environments.

Connection

Mass customization enhances manufacturing flexibility by producing personalized products at scale, while Just-in-Time (JIT) inventory systems reduce waste by aligning raw material orders closely with production schedules. The integration of mass customization with JIT enables manufacturers to rapidly respond to specific customer demands without excessive inventory costs or delays. This synergy optimizes resource utilization and accelerates production cycles, driving efficiency and customer satisfaction in modern manufacturing processes.

Key Terms

Inventory Management

Just-in-Time (JIT) inventory management minimizes stock levels by synchronizing production with demand, reducing holding costs and waste. Mass customization balances efficient inventory with personalized production by maintaining modular components and flexible manufacturing systems. Explore how these strategies optimize inventory workflows and improve supply chain responsiveness.

Production Flexibility

Just-in-Time (JIT) production emphasizes minimizing inventory and responding swiftly to demand fluctuations by producing goods only as needed, enhancing production flexibility through lean processes and reduced lead times. Mass customization integrates the efficiency of mass production with the ability to tailor products to individual customer preferences, allowing manufacturers to adapt production lines quickly while maintaining economies of scale. Explore strategies to optimize production flexibility by balancing JIT principles and mass customization techniques.

Lead Time

Just-in-Time (JIT) manufacturing significantly reduces lead time by producing goods only as needed, minimizing inventory levels and accelerating order fulfillment. Mass customization balances personalized product options with efficient production processes, often resulting in moderate lead times that are longer than JIT but shorter than traditional mass production. Explore detailed strategies to optimize lead time in both approaches for enhanced operational efficiency.

Source and External Links

Just-in-Time (JIT) Inventory: A Definition and Comprehensive Guide - JIT is an inventory management strategy developed by Toyota to minimize waste by receiving materials only as they are needed for production, emphasizing continuous improvement and supplier coordination.

JIT Just-in-Time manufacturing - JIT is a management philosophy focused on producing exactly what is needed when it is needed, eliminating all types of waste through methods such as quality control at the source, continuous improvement, and simplified production systems.

What is Just-in-Time Manufacturing (JIT)? - Planview - JIT manufacturing aims to reduce production flow times and response times by limiting inventory and applying disciplined techniques including setup reduction, uniform plant load, and balanced workflow.

dowidth.com

dowidth.com