Additive manufacturing builds objects layer by layer using digital models, enabling complex geometries and material efficiency that conventional manufacturing, which relies on subtractive processes like machining or molding, often cannot achieve. This technology reduces waste, shortens production cycles, and allows for rapid prototyping, contrasting with the longer lead times and material constraints of traditional manufacturing methods. Discover how integrating additive manufacturing transforms production workflows and drives innovation in the manufacturing industry.

Why it is important

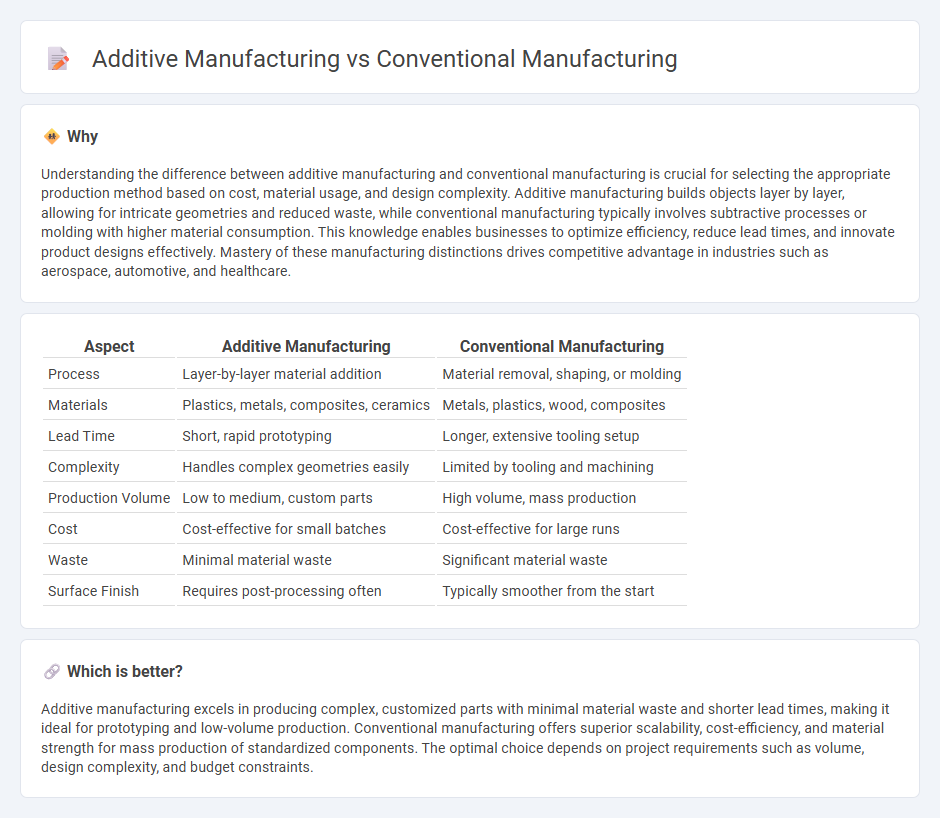

Understanding the difference between additive manufacturing and conventional manufacturing is crucial for selecting the appropriate production method based on cost, material usage, and design complexity. Additive manufacturing builds objects layer by layer, allowing for intricate geometries and reduced waste, while conventional manufacturing typically involves subtractive processes or molding with higher material consumption. This knowledge enables businesses to optimize efficiency, reduce lead times, and innovate product designs effectively. Mastery of these manufacturing distinctions drives competitive advantage in industries such as aerospace, automotive, and healthcare.

Comparison Table

| Aspect | Additive Manufacturing | Conventional Manufacturing |

|---|---|---|

| Process | Layer-by-layer material addition | Material removal, shaping, or molding |

| Materials | Plastics, metals, composites, ceramics | Metals, plastics, wood, composites |

| Lead Time | Short, rapid prototyping | Longer, extensive tooling setup |

| Complexity | Handles complex geometries easily | Limited by tooling and machining |

| Production Volume | Low to medium, custom parts | High volume, mass production |

| Cost | Cost-effective for small batches | Cost-effective for large runs |

| Waste | Minimal material waste | Significant material waste |

| Surface Finish | Requires post-processing often | Typically smoother from the start |

Which is better?

Additive manufacturing excels in producing complex, customized parts with minimal material waste and shorter lead times, making it ideal for prototyping and low-volume production. Conventional manufacturing offers superior scalability, cost-efficiency, and material strength for mass production of standardized components. The optimal choice depends on project requirements such as volume, design complexity, and budget constraints.

Connection

Additive manufacturing complements conventional manufacturing by enabling rapid prototyping and complex geometries that are difficult to achieve with traditional machining processes. Both methods often integrate within hybrid systems, where additive techniques build up components followed by subtractive finishing for precision and surface quality. This synergy enhances production flexibility, reduces material waste, and accelerates product development cycles across industries.

Key Terms

Subtractive Process

Subtractive manufacturing involves removing material from a solid block using CNC machines, lathes, or milling cutters to achieve precise dimensions and smooth surfaces. This process excels in producing high-strength parts from metals and plastics with tight tolerances and is widely used in aerospace and automotive industries. Explore further to understand how subtractive methods compare with additive technologies in efficiency, cost, and design flexibility.

Layer-by-Layer Fabrication

Conventional manufacturing relies on subtractive processes such as milling and machining, removing material from a solid block to create parts, whereas additive manufacturing builds components layer-by-layer, enabling complex geometries and material efficiency. Additive manufacturing techniques like selective laser sintering (SLS) and fused deposition modeling (FDM) offer precise control over layer thickness and can produce lightweight structures impossible with traditional methods. Explore the latest advancements in layer-by-layer fabrication to understand how additive manufacturing is revolutionizing production capabilities.

Material Waste

Conventional manufacturing generates significant material waste through subtractive processes like machining, which remove excess material from raw stock. Additive manufacturing builds parts layer by layer, minimizing waste by only using material necessary for the final geometry, significantly reducing scrap and excess. Explore more about how additive manufacturing drives sustainability in production by reducing waste.

Source and External Links

Conventional Manufacturing Process | Types, Advantages ... - Conventional manufacturing involves traditional, well-established processes like casting, forging, stamping, and machining to transform raw materials into finished goods, often through structured, sequential production stages with significant manual labor.

CONVENTIONAL MANUFACTURING - PDTS - Conventional manufacturing typically uses manual machining processes such as milling, turning, and sheet metal fabrication, focusing on subtractive methods and assembly operations like welding and fastening to produce parts or products.

3D Printing vs. Traditional Manufacturing: Differences and Comparison - Conventional manufacturing is characterized by subtractive techniques (molding, forming, machining, joining), excels in mass production and material selection, but is less efficient for complex geometries, customization, and low-volume runs compared to additive manufacturing.

dowidth.com

dowidth.com