Lights out manufacturing relies on fully automated, unmanned production processes that operate continuously without human intervention, maximizing efficiency and reducing labor costs. Just-in-time (JIT) manufacturing focuses on minimizing inventory by receiving goods only as they are needed in the production process, thereby reducing waste and improving cash flow. Discover how these innovative manufacturing strategies can transform operational efficiency and competitiveness.

Why it is important

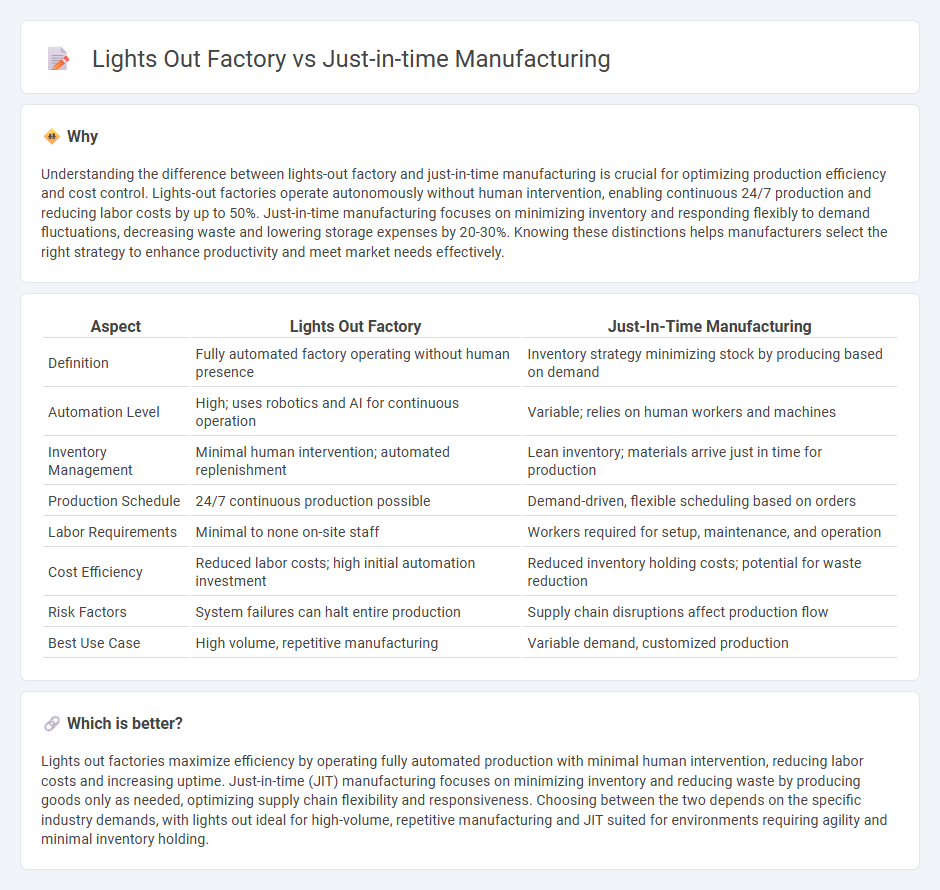

Understanding the difference between lights-out factory and just-in-time manufacturing is crucial for optimizing production efficiency and cost control. Lights-out factories operate autonomously without human intervention, enabling continuous 24/7 production and reducing labor costs by up to 50%. Just-in-time manufacturing focuses on minimizing inventory and responding flexibly to demand fluctuations, decreasing waste and lowering storage expenses by 20-30%. Knowing these distinctions helps manufacturers select the right strategy to enhance productivity and meet market needs effectively.

Comparison Table

| Aspect | Lights Out Factory | Just-In-Time Manufacturing |

|---|---|---|

| Definition | Fully automated factory operating without human presence | Inventory strategy minimizing stock by producing based on demand |

| Automation Level | High; uses robotics and AI for continuous operation | Variable; relies on human workers and machines |

| Inventory Management | Minimal human intervention; automated replenishment | Lean inventory; materials arrive just in time for production |

| Production Schedule | 24/7 continuous production possible | Demand-driven, flexible scheduling based on orders |

| Labor Requirements | Minimal to none on-site staff | Workers required for setup, maintenance, and operation |

| Cost Efficiency | Reduced labor costs; high initial automation investment | Reduced inventory holding costs; potential for waste reduction |

| Risk Factors | System failures can halt entire production | Supply chain disruptions affect production flow |

| Best Use Case | High volume, repetitive manufacturing | Variable demand, customized production |

Which is better?

Lights out factories maximize efficiency by operating fully automated production with minimal human intervention, reducing labor costs and increasing uptime. Just-in-time (JIT) manufacturing focuses on minimizing inventory and reducing waste by producing goods only as needed, optimizing supply chain flexibility and responsiveness. Choosing between the two depends on the specific industry demands, with lights out ideal for high-volume, repetitive manufacturing and JIT suited for environments requiring agility and minimal inventory holding.

Connection

Lights out factories automate production with minimal or no human presence, enhancing efficiency and reducing labor costs. Just-in-time manufacturing relies on precise timing and inventory control, which is facilitated by automated systems in lights out factories. Combining these approaches streamlines operations, minimizes waste, and accelerates production cycles in modern manufacturing.

Key Terms

Inventory Management

Just-in-time (JIT) manufacturing minimizes inventory levels by synchronizing raw material deliveries with production schedules, reducing holding costs and waste. Lights-out factories leverage automation and AI to optimize inventory tracking and demand forecasting, ensuring continuous operation with minimal human intervention. Explore these innovative inventory management strategies for enhanced efficiency and cost savings.

Automation

Just-in-time manufacturing minimizes inventory and reduces waste by coordinating production closely with demand, relying on precise timing and human intervention, while lights-out factories leverage full automation and robotics to operate without human presence, maximizing efficiency and continuous production. Automation in lights-out factories integrates advanced AI, machine learning, and IoT sensors to optimize processes, reduce errors, and ensure consistent output, surpassing traditional just-in-time methods largely dependent on manual coordination. Explore how combining these automation strategies can transform manufacturing efficiency and responsiveness.

Human Labor

Just-in-time manufacturing relies heavily on skilled human labor to precisely time inventory deliveries, reduce waste, and maintain efficient production flow. Lights out factories minimize human involvement through automation, enabling continuous, round-the-clock production without onsite workers. Explore the impact of human labor on manufacturing efficiency and innovation to understand which approach suits your business needs.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time (JIT) manufacturing is a strategy that increases efficiency and reduces waste by producing goods only as they are needed, enabling companies to better match supply with demand, lower inventory costs, and improve product quality through continuous monitoring and supplier collaboration.

Lean manufacturing - Wikipedia - Just-in-time manufacturing focuses on producing goods at the rate of customer demand (takt time), utilizing methodologies such as defect elimination, setup reduction, small lot sizes, and pull systems like kanban to streamline production and minimize waste.

What is just-in-time manufacturing (JIT manufacturing)? - TechTarget - JIT manufacturing is a production model where items are made to meet actual demand, avoiding overproduction and excess inventory, which helps organizations cut costs, increase efficiency, and accelerate delivery by eliminating waste such as unnecessary wait times and excessive stock.

dowidth.com

dowidth.com