Decentralized manufacturing distributes production across multiple localized facilities, enhancing flexibility and reducing lead times compared to centralized approaches. Mass customization leverages advanced technologies to produce tailored products at near mass production efficiency, meeting individual customer preferences without sacrificing scale. Explore how these innovative manufacturing strategies revolutionize supply chains and customer satisfaction.

Why it is important

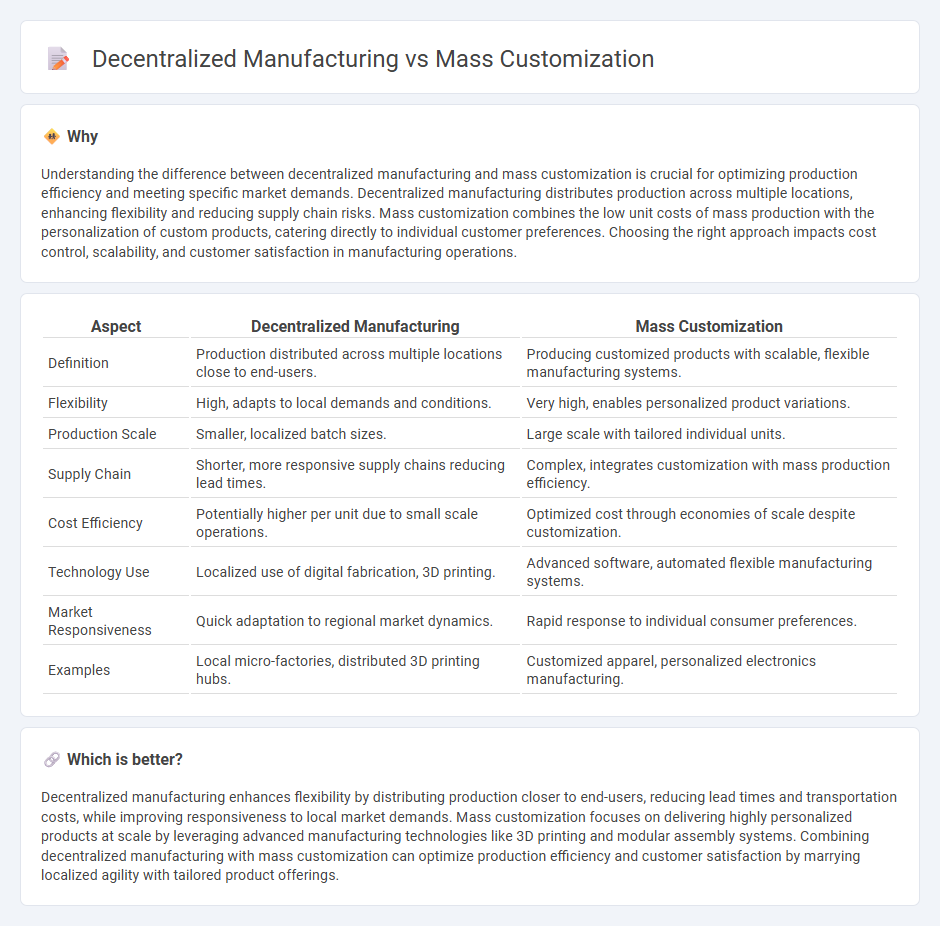

Understanding the difference between decentralized manufacturing and mass customization is crucial for optimizing production efficiency and meeting specific market demands. Decentralized manufacturing distributes production across multiple locations, enhancing flexibility and reducing supply chain risks. Mass customization combines the low unit costs of mass production with the personalization of custom products, catering directly to individual customer preferences. Choosing the right approach impacts cost control, scalability, and customer satisfaction in manufacturing operations.

Comparison Table

| Aspect | Decentralized Manufacturing | Mass Customization |

|---|---|---|

| Definition | Production distributed across multiple locations close to end-users. | Producing customized products with scalable, flexible manufacturing systems. |

| Flexibility | High, adapts to local demands and conditions. | Very high, enables personalized product variations. |

| Production Scale | Smaller, localized batch sizes. | Large scale with tailored individual units. |

| Supply Chain | Shorter, more responsive supply chains reducing lead times. | Complex, integrates customization with mass production efficiency. |

| Cost Efficiency | Potentially higher per unit due to small scale operations. | Optimized cost through economies of scale despite customization. |

| Technology Use | Localized use of digital fabrication, 3D printing. | Advanced software, automated flexible manufacturing systems. |

| Market Responsiveness | Quick adaptation to regional market dynamics. | Rapid response to individual consumer preferences. |

| Examples | Local micro-factories, distributed 3D printing hubs. | Customized apparel, personalized electronics manufacturing. |

Which is better?

Decentralized manufacturing enhances flexibility by distributing production closer to end-users, reducing lead times and transportation costs, while improving responsiveness to local market demands. Mass customization focuses on delivering highly personalized products at scale by leveraging advanced manufacturing technologies like 3D printing and modular assembly systems. Combining decentralized manufacturing with mass customization can optimize production efficiency and customer satisfaction by marrying localized agility with tailored product offerings.

Connection

Decentralized manufacturing leverages localized production facilities to enable mass customization by producing tailored products closer to end consumers, reducing lead times and logistics costs. This approach integrates advanced technologies such as 3D printing and IoT to facilitate flexible, on-demand manufacturing processes that meet specific customer requirements. As a result, companies achieve greater responsiveness and efficiency by combining decentralized networks with personalized product offerings.

Key Terms

Flexibility

Mass customization offers high flexibility by enabling personalized products at scale through centralized control and advanced technology, ensuring consistent quality and rapid response to market trends. Decentralized manufacturing enhances flexibility by distributing production closer to end-users, reducing lead times, and allowing adaptive local customization based on specific regional demands. Explore the advantages of each approach to discover which manufacturing strategy best suits your business goals.

Scalability

Mass customization enables scalable production by integrating flexible manufacturing systems and advanced automation, allowing companies to efficiently produce personalized products at higher volumes. Decentralized manufacturing enhances scalability by distributing production across multiple localized sites, reducing lead times, and responding swiftly to regional demand fluctuations. Explore the comparative advantages of both methods to optimize your scalable manufacturing strategy.

Supply Chain

Mass customization enhances supply chain flexibility by enabling tailored products with minimized lead times through advanced production techniques and integrated demand forecasting. Decentralized manufacturing distributes production closer to end-users, reducing transportation costs and risks while improving responsiveness to local market changes. Explore how integrating these approaches optimizes supply chain efficiency and customer satisfaction.

Source and External Links

Mass Customization: A Complete Guide - Mass customization is a business strategy that provides personalized products and services cost-effectively by understanding customer needs, using technologies like 3D printing, designing for scalability, and automating manufacturing processes.

Guide to Mass Customization - Mass customization combines customization with low costs, with key types including collaborative customization (co-creation with customers) and adaptive customization (standard product modified by users), exemplified by Nike's customizable shoes.

Mass customization - It uses flexible computer-aided systems to produce individually customized goods at near mass production efficiency, enabling firms to deliver high variety without significantly increased costs through strategies like modular design and delayed differentiation.

dowidth.com

dowidth.com