Industrial symbiosis enhances manufacturing sustainability by promoting resource sharing and waste exchange among industries, reducing environmental impact and operational costs. Green manufacturing focuses on eco-friendly production processes, utilizing renewable materials and energy-efficient technologies to minimize pollution and carbon footprint. Explore the benefits and applications of industrial symbiosis versus green manufacturing to optimize your production sustainability strategies.

Why it is important

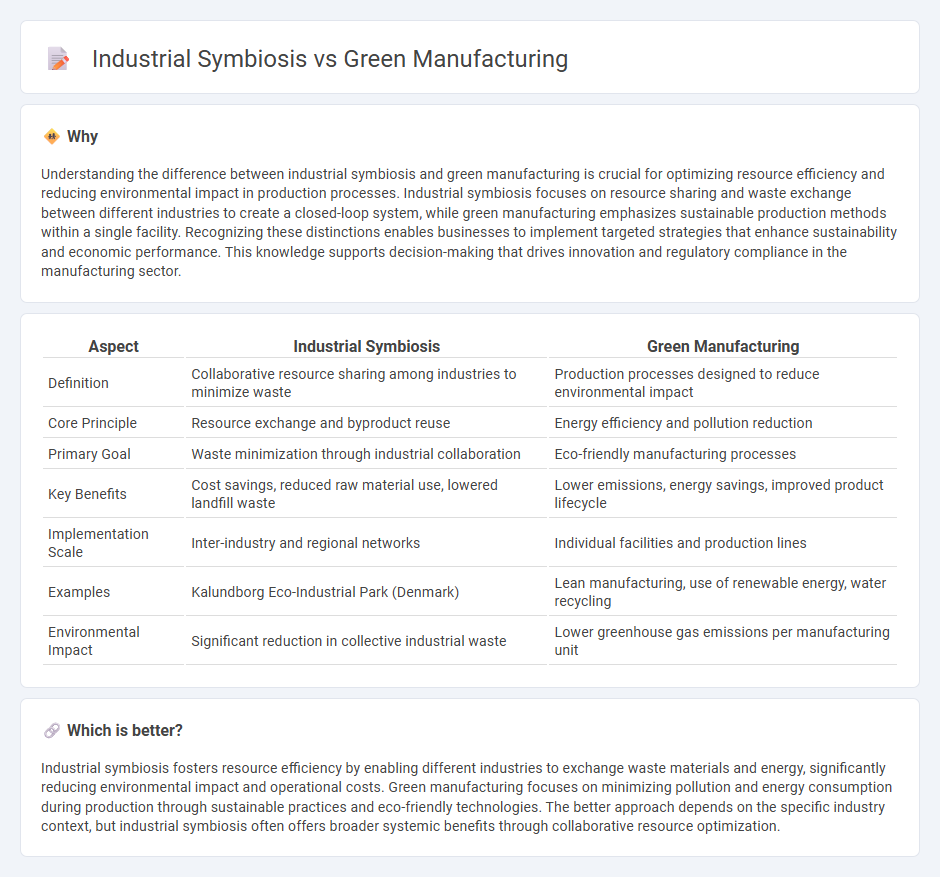

Understanding the difference between industrial symbiosis and green manufacturing is crucial for optimizing resource efficiency and reducing environmental impact in production processes. Industrial symbiosis focuses on resource sharing and waste exchange between different industries to create a closed-loop system, while green manufacturing emphasizes sustainable production methods within a single facility. Recognizing these distinctions enables businesses to implement targeted strategies that enhance sustainability and economic performance. This knowledge supports decision-making that drives innovation and regulatory compliance in the manufacturing sector.

Comparison Table

| Aspect | Industrial Symbiosis | Green Manufacturing |

|---|---|---|

| Definition | Collaborative resource sharing among industries to minimize waste | Production processes designed to reduce environmental impact |

| Core Principle | Resource exchange and byproduct reuse | Energy efficiency and pollution reduction |

| Primary Goal | Waste minimization through industrial collaboration | Eco-friendly manufacturing processes |

| Key Benefits | Cost savings, reduced raw material use, lowered landfill waste | Lower emissions, energy savings, improved product lifecycle |

| Implementation Scale | Inter-industry and regional networks | Individual facilities and production lines |

| Examples | Kalundborg Eco-Industrial Park (Denmark) | Lean manufacturing, use of renewable energy, water recycling |

| Environmental Impact | Significant reduction in collective industrial waste | Lower greenhouse gas emissions per manufacturing unit |

Which is better?

Industrial symbiosis fosters resource efficiency by enabling different industries to exchange waste materials and energy, significantly reducing environmental impact and operational costs. Green manufacturing focuses on minimizing pollution and energy consumption during production through sustainable practices and eco-friendly technologies. The better approach depends on the specific industry context, but industrial symbiosis often offers broader systemic benefits through collaborative resource optimization.

Connection

Industrial symbiosis enhances green manufacturing by promoting resource efficiency through the exchange of materials, energy, and by-products among industries. This collaborative approach reduces waste, lowers environmental impact, and drives sustainable production processes. Integrating industrial symbiosis within green manufacturing frameworks supports circular economy principles and optimizes supply chain sustainability.

Key Terms

Resource Efficiency

Green manufacturing emphasizes minimizing waste and energy consumption during production to enhance resource efficiency and reduce environmental impact. Industrial symbiosis involves multiple industries collaborating to exchange materials, energy, and by-products, creating a circular flow that significantly boosts resource utilization and reduces landfill dependency. Explore how integrating these strategies can revolutionize sustainable industrial practices.

Waste Minimization

Green manufacturing emphasizes reducing waste through efficient resource use, cleaner production processes, and recycling within a single facility to achieve environmental sustainability. Industrial symbiosis extends waste minimization by enabling multiple industries to collaboratively exchange by-products and materials, transforming one industry's waste into another's resource, thus reducing overall waste generation across the industrial ecosystem. Explore more about how these strategies complement each other in advancing sustainable waste management.

Circular Economy

Green manufacturing prioritizes reducing waste and energy consumption through sustainable production processes, aligning closely with Circular Economy principles by maximizing resource efficiency. Industrial symbiosis extends this concept by facilitating resource sharing and waste exchange between different industries to create closed-loop systems, thereby enhancing material reuse and minimizing environmental impact. Explore how integrating green manufacturing and industrial symbiosis can revolutionize Circular Economy strategies for sustainable industrial growth.

Source and External Links

What Is Green Manufacturing? - Green manufacturing, also called sustainable manufacturing, involves producing products in a way that reduces carbon footprint by minimizing environmental impact, conserving energy, and using renewable resources, which benefits both the environment and businesses through cost savings and regulatory compliance.

What is Green Manufacturing? (Plus 5 Steps to a Greener ...) - Green manufacturing focuses on minimizing environmental impacts while maximizing resource efficiency by adopting eco-friendly processes like lean manufacturing to reduce waste and improve productivity.

Green Manufacturing: The Business Benefits of Sustainability - Green manufacturing involves using fewer pollutants and natural resources to reduce waste and emissions, benefiting the environment and helping companies reduce costs and improve operational efficiency.

dowidth.com

dowidth.com