Collaborative robots (cobots) enhance manufacturing flexibility by working safely alongside human operators, enabling real-time adjustments and reducing setup times. Automation cells, on the other hand, offer high-speed, repetitive task execution with minimal human intervention, improving precision and output consistency. Explore how combining cobots and automation cells can revolutionize your production processes.

Why it is important

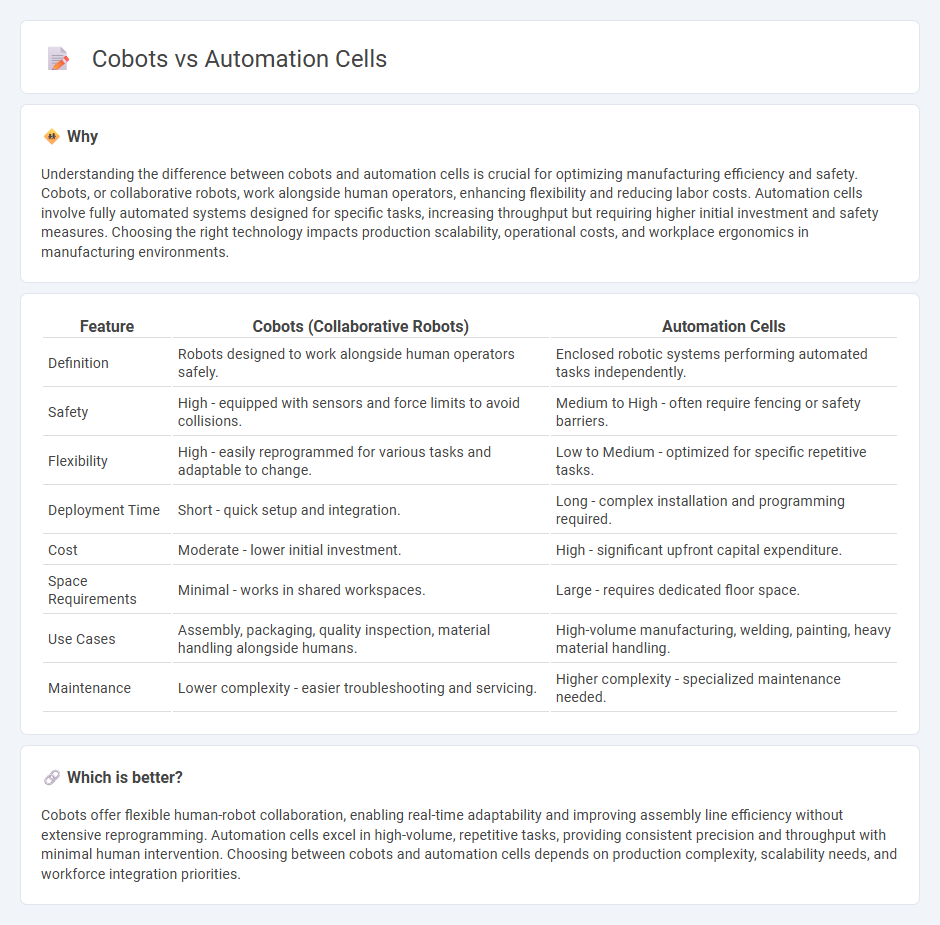

Understanding the difference between cobots and automation cells is crucial for optimizing manufacturing efficiency and safety. Cobots, or collaborative robots, work alongside human operators, enhancing flexibility and reducing labor costs. Automation cells involve fully automated systems designed for specific tasks, increasing throughput but requiring higher initial investment and safety measures. Choosing the right technology impacts production scalability, operational costs, and workplace ergonomics in manufacturing environments.

Comparison Table

| Feature | Cobots (Collaborative Robots) | Automation Cells |

|---|---|---|

| Definition | Robots designed to work alongside human operators safely. | Enclosed robotic systems performing automated tasks independently. |

| Safety | High - equipped with sensors and force limits to avoid collisions. | Medium to High - often require fencing or safety barriers. |

| Flexibility | High - easily reprogrammed for various tasks and adaptable to change. | Low to Medium - optimized for specific repetitive tasks. |

| Deployment Time | Short - quick setup and integration. | Long - complex installation and programming required. |

| Cost | Moderate - lower initial investment. | High - significant upfront capital expenditure. |

| Space Requirements | Minimal - works in shared workspaces. | Large - requires dedicated floor space. |

| Use Cases | Assembly, packaging, quality inspection, material handling alongside humans. | High-volume manufacturing, welding, painting, heavy material handling. |

| Maintenance | Lower complexity - easier troubleshooting and servicing. | Higher complexity - specialized maintenance needed. |

Which is better?

Cobots offer flexible human-robot collaboration, enabling real-time adaptability and improving assembly line efficiency without extensive reprogramming. Automation cells excel in high-volume, repetitive tasks, providing consistent precision and throughput with minimal human intervention. Choosing between cobots and automation cells depends on production complexity, scalability needs, and workforce integration priorities.

Connection

Cobots integrate seamlessly with automation cells through advanced communication protocols such as OPC UA and Ethernet/IP, enabling synchronized task execution and real-time data exchange. These collaborative robots enhance manufacturing efficiency by working alongside human operators within automation cells, adapting dynamically to varying workloads. Integration of cobots with automation cells supports predictive maintenance and process optimization through IoT connectivity and AI-driven analytics.

Key Terms

Flexibility

Automation cells offer high precision and consistent output through fully programmed robotic systems, ideal for repetitive tasks with minimal variation. Cobots provide superior flexibility by working safely alongside human operators, adapting quickly to changing workflows and diverse applications without extensive programming. Explore how choosing between automation cells and cobots can optimize your manufacturing flexibility.

Human-robot collaboration

Human-robot collaboration thrives in environments where automation cells and cobots coexist, enhancing productivity through seamless interaction. Automation cells excel at repetitive, high-precision tasks within isolated workstations, while cobots offer flexibility by working safely alongside human operators in shared spaces. Discover how integrating both can transform operational efficiency and workplace safety.

Integration complexity

Automation cells often require extensive integration involving programmable logic controllers (PLCs), robotics arms, and safety systems tailored for specific tasks, which can lead to high setup times and engineering costs. Cobots, or collaborative robots, are designed with user-friendly programming interfaces and built-in safety features, enabling easier integration alongside human operators with minimal disruption to existing workflows. Explore how these differences impact your production efficiency and operational scalability.

Source and External Links

What Is a Robotic Cells? Types and Benefits Explained - Robotic cells are specialized enclosed workstations integrating one or more robots with peripheral equipment to perform automated tasks such as assembly, palletizing, vision-guided inspection, and collaborative human-robot work, designed to improve precision and efficiency in manufacturing.

Robot cells: the complete guide - Robot cells combine industrial robots with tools and safety measures within an enclosed workspace, enabling robots to operate at higher speeds safely and improving productivity and ease of deployment in existing factory floors.

Assembly Automation Cells & Equipment for Plastic Molding - Automated assembly cells are custom-designed robotic workstations that offer flexible, high-speed, and precise assembly solutions, often equipped with vision inspection, conveyors, and feeders for plastic molding and other manufacturing applications.

dowidth.com

dowidth.com