Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to streamline complex manufacturing workflows, significantly enhancing efficiency and reducing human error. In contrast, additive manufacturing, commonly known as 3D printing, builds products layer by layer from digital models, enabling rapid prototyping and customized production with minimized material waste. Explore the distinct advantages and applications of hyperautomation and additive manufacturing to optimize your manufacturing strategy.

Why it is important

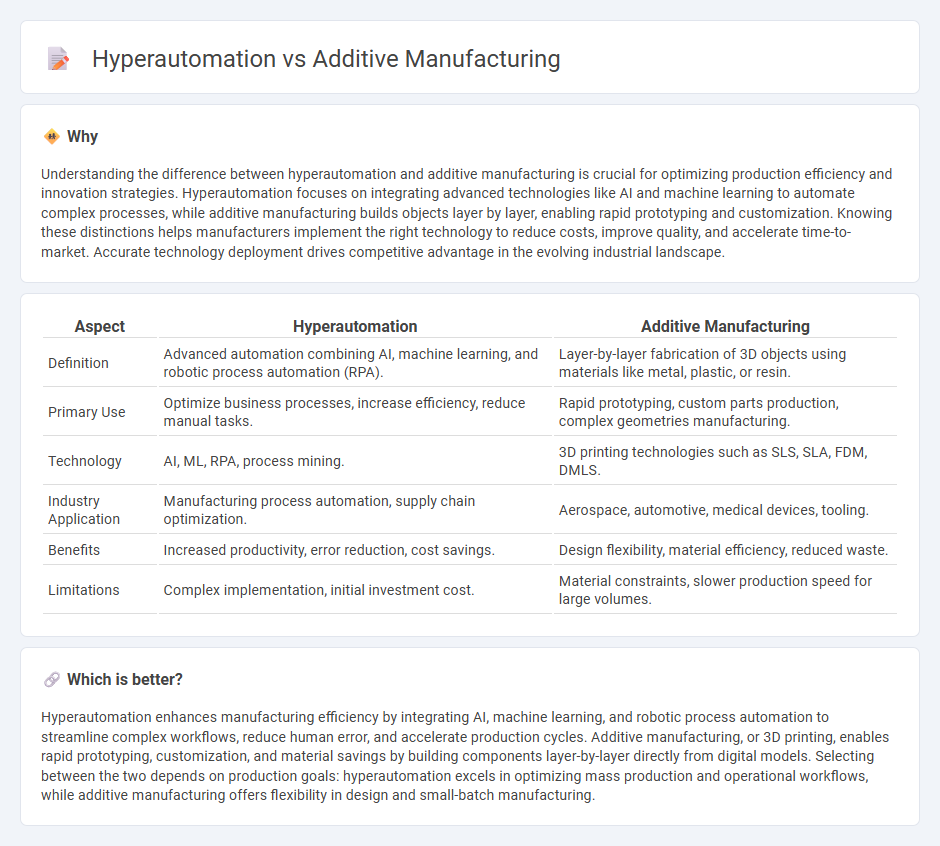

Understanding the difference between hyperautomation and additive manufacturing is crucial for optimizing production efficiency and innovation strategies. Hyperautomation focuses on integrating advanced technologies like AI and machine learning to automate complex processes, while additive manufacturing builds objects layer by layer, enabling rapid prototyping and customization. Knowing these distinctions helps manufacturers implement the right technology to reduce costs, improve quality, and accelerate time-to-market. Accurate technology deployment drives competitive advantage in the evolving industrial landscape.

Comparison Table

| Aspect | Hyperautomation | Additive Manufacturing |

|---|---|---|

| Definition | Advanced automation combining AI, machine learning, and robotic process automation (RPA). | Layer-by-layer fabrication of 3D objects using materials like metal, plastic, or resin. |

| Primary Use | Optimize business processes, increase efficiency, reduce manual tasks. | Rapid prototyping, custom parts production, complex geometries manufacturing. |

| Technology | AI, ML, RPA, process mining. | 3D printing technologies such as SLS, SLA, FDM, DMLS. |

| Industry Application | Manufacturing process automation, supply chain optimization. | Aerospace, automotive, medical devices, tooling. |

| Benefits | Increased productivity, error reduction, cost savings. | Design flexibility, material efficiency, reduced waste. |

| Limitations | Complex implementation, initial investment cost. | Material constraints, slower production speed for large volumes. |

Which is better?

Hyperautomation enhances manufacturing efficiency by integrating AI, machine learning, and robotic process automation to streamline complex workflows, reduce human error, and accelerate production cycles. Additive manufacturing, or 3D printing, enables rapid prototyping, customization, and material savings by building components layer-by-layer directly from digital models. Selecting between the two depends on production goals: hyperautomation excels in optimizing mass production and operational workflows, while additive manufacturing offers flexibility in design and small-batch manufacturing.

Connection

Hyperautomation enhances additive manufacturing by integrating advanced robotics, AI-driven process optimization, and real-time data analytics to streamline production cycles and reduce errors. Additive manufacturing benefits from hyperautomation through automated quality control, adaptive machine learning algorithms, and predictive maintenance, increasing precision and efficiency in producing complex components. The synergy between hyperautomation and additive manufacturing fosters scalable, flexible, and highly efficient manufacturing ecosystems.

Key Terms

**Additive Manufacturing:**

Additive Manufacturing (AM) is a transformative production process that builds objects layer by layer using materials such as plastics, metals, or composites, enabling complex geometries and customization that traditional manufacturing cannot achieve. Key technologies in AM include Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA), contributing to reduced waste and faster prototyping cycles in industries like aerospace, healthcare, and automotive. Explore deeper insights into how Additive Manufacturing drives innovation and efficiency in modern production workflows.

3D Printing

Additive manufacturing, commonly known as 3D printing, enables the layer-by-layer fabrication of complex parts using materials like plastics, metals, and ceramics, revolutionizing prototyping and production efficiency. Hyperautomation integrates AI-driven technologies and robotic process automation (RPA) to streamline end-to-end manufacturing workflows but typically doesn't directly alter the physical production process like additive manufacturing does. Explore how combining 3D printing with hyperautomation can enhance smart manufacturing by visiting our detailed insights page.

Layer-by-Layer Fabrication

Additive manufacturing utilizes layer-by-layer fabrication to build complex 3D objects directly from digital models, enhancing precision and reducing material waste. Hyperautomation integrates advanced technologies like AI and robotics to automate business processes, but does not physically fabricate products layer-by-layer. Explore the distinctions and applications of these innovations to understand their impact on manufacturing and automation sectors.

Source and External Links

Additive manufacturing, explained - Additive manufacturing is the process of creating objects layer by layer from digital designs, typically using 3D printing, and has evolved from rapid prototyping in the 1980s to producing functional parts today with a wide range of materials like polymers, metals, and ceramics.

Additive manufacturing | NIST - Additive manufacturing (AM) fabricates three-dimensional parts by building them up layer-by-layer from digital files, enabling complex designs with less waste, and is applied in industries including aerospace and biomedical implants.

What Is Additive Manufacturing? | 3D Printing Simulation ... - Additive manufacturing builds 3D objects from digital models through layering materials like metals or polymers using several print technologies such as powder bed fusion, material extrusion, binder jetting, photopolymerization, and direct energy deposition.

dowidth.com

dowidth.com