Robotic Process Automation (RPA) enhances manufacturing by automating routine, rule-based tasks, improving efficiency and reducing human error in administrative processes. Manufacturing Execution Systems (MES) provide real-time monitoring and control of production workflows, ensuring quality management, traceability, and operational transparency on the factory floor. Explore how integrating RPA with MES can optimize manufacturing performance and drive digital transformation.

Why it is important

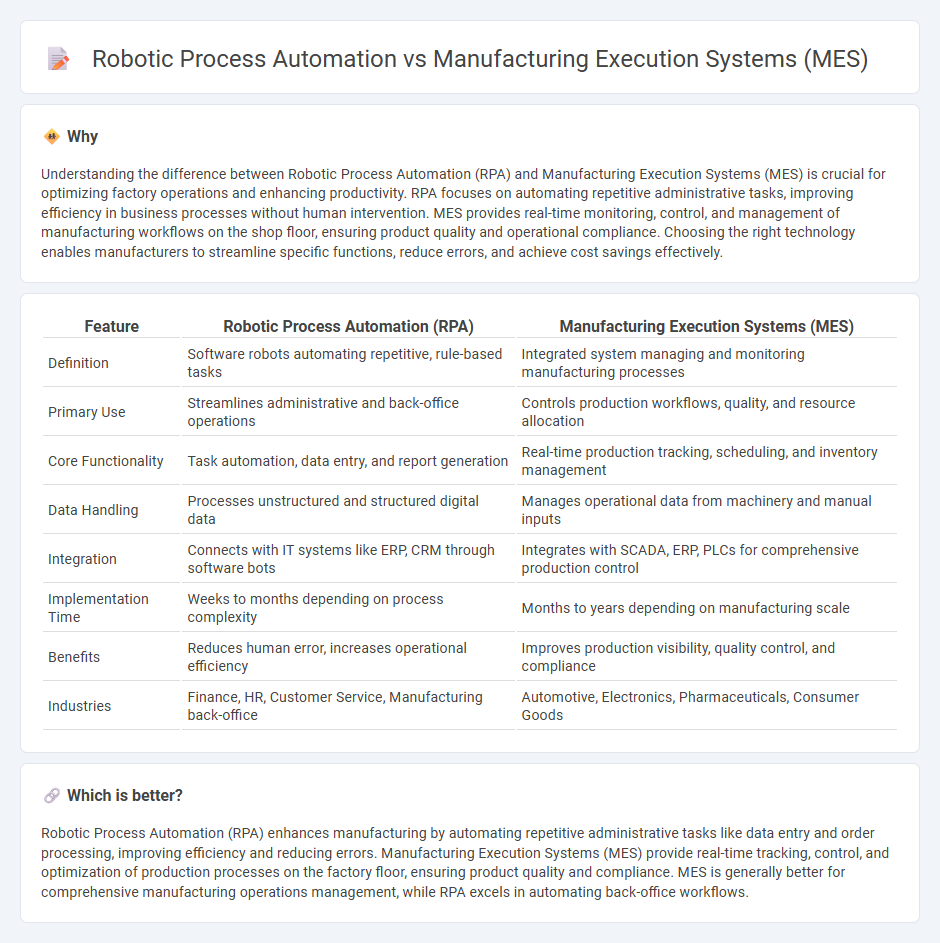

Understanding the difference between Robotic Process Automation (RPA) and Manufacturing Execution Systems (MES) is crucial for optimizing factory operations and enhancing productivity. RPA focuses on automating repetitive administrative tasks, improving efficiency in business processes without human intervention. MES provides real-time monitoring, control, and management of manufacturing workflows on the shop floor, ensuring product quality and operational compliance. Choosing the right technology enables manufacturers to streamline specific functions, reduce errors, and achieve cost savings effectively.

Comparison Table

| Feature | Robotic Process Automation (RPA) | Manufacturing Execution Systems (MES) |

|---|---|---|

| Definition | Software robots automating repetitive, rule-based tasks | Integrated system managing and monitoring manufacturing processes |

| Primary Use | Streamlines administrative and back-office operations | Controls production workflows, quality, and resource allocation |

| Core Functionality | Task automation, data entry, and report generation | Real-time production tracking, scheduling, and inventory management |

| Data Handling | Processes unstructured and structured digital data | Manages operational data from machinery and manual inputs |

| Integration | Connects with IT systems like ERP, CRM through software bots | Integrates with SCADA, ERP, PLCs for comprehensive production control |

| Implementation Time | Weeks to months depending on process complexity | Months to years depending on manufacturing scale |

| Benefits | Reduces human error, increases operational efficiency | Improves production visibility, quality control, and compliance |

| Industries | Finance, HR, Customer Service, Manufacturing back-office | Automotive, Electronics, Pharmaceuticals, Consumer Goods |

Which is better?

Robotic Process Automation (RPA) enhances manufacturing by automating repetitive administrative tasks like data entry and order processing, improving efficiency and reducing errors. Manufacturing Execution Systems (MES) provide real-time tracking, control, and optimization of production processes on the factory floor, ensuring product quality and compliance. MES is generally better for comprehensive manufacturing operations management, while RPA excels in automating back-office workflows.

Connection

Robotic Process Automation (RPA) integrates seamlessly with Manufacturing Execution Systems (MES) by streamlining data collection, real-time monitoring, and process control within production environments. MES platforms leverage RPA to automate repetitive tasks such as inventory updates, quality inspections, and production scheduling, enhancing overall operational efficiency. This convergence optimizes manufacturing workflows, reduces human error, and accelerates decision-making across the shop floor.

Key Terms

Real-time production monitoring

Manufacturing Execution Systems (MES) provide comprehensive real-time production monitoring by capturing data directly from the shop floor, enabling tracking of work-in-progress, machine status, and quality metrics to optimize manufacturing operations. Robotic Process Automation (RPA) automates repetitive administrative tasks but lacks the direct integration with physical production equipment that MES offers for real-time visibility and control. Discover how MES tools transform factory floors with real-time data insights and actionable intelligence.

Workflow automation

Manufacturing Execution Systems (MES) streamline production workflows by integrating real-time data from machines and operators to enhance operational efficiency and quality control. Robotic Process Automation (RPA) focuses on automating repetitive administrative tasks within workflows, such as data entry and report generation, improving accuracy and speed in business processes. Explore how MES and RPA can synergistically revolutionize workflow automation in your manufacturing operations.

Data integration

Manufacturing Execution Systems (MES) provide real-time data integration across production processes, enabling seamless tracking of materials, equipment status, and workflow analytics to optimize operational efficiency. Robotic Process Automation (RPA) enhances data management by automating repetitive data entry and extraction tasks, but lacks MES's depth in handling complex manufacturing data streams and real-time process controls. Explore how MES and RPA complement each other in data integration to transform industrial operations.

Source and External Links

Manufacturing execution system - MES are computerized software systems that oversee and optimize real-time production operations by tracking raw materials to finished goods, managing resources, quality, and documentation, and integrating with ERP systems to boost manufacturing efficiency and transparency.

Manufacturing Execution System (MES) Software | DELMIA - MES software enables manufacturers to coordinate people, processes, equipment, and materials globally, digitizing manufacturing processes to improve efficiency, quality, and real-time visibility while integrating with ERP for standardized production management.

What is a Manufacturing Execution System (MES)? - MES is a software solution that bridges enterprise planning systems and shop floor control by monitoring production in real time, tracking transformation processes, optimizing scheduling and resource allocation, ensuring quality and compliance, and enhancing decision-making to improve overall equipment effectiveness.

dowidth.com

dowidth.com