Biofabrication encompasses a wide range of techniques aimed at creating complex biological structures through the assembly of living cells, biomaterials, and growth factors, while bioprinting specifically refers to the layer-by-layer deposition of bioinks to produce tissue-like constructs. Advances in biofabrication drive innovations in regenerative medicine, drug testing, and artificial organ development, with bioprinting providing precise spatial control of cell placement for enhanced functionality. Discover more about how these cutting-edge manufacturing methods are transforming healthcare and biomedical research.

Why it is important

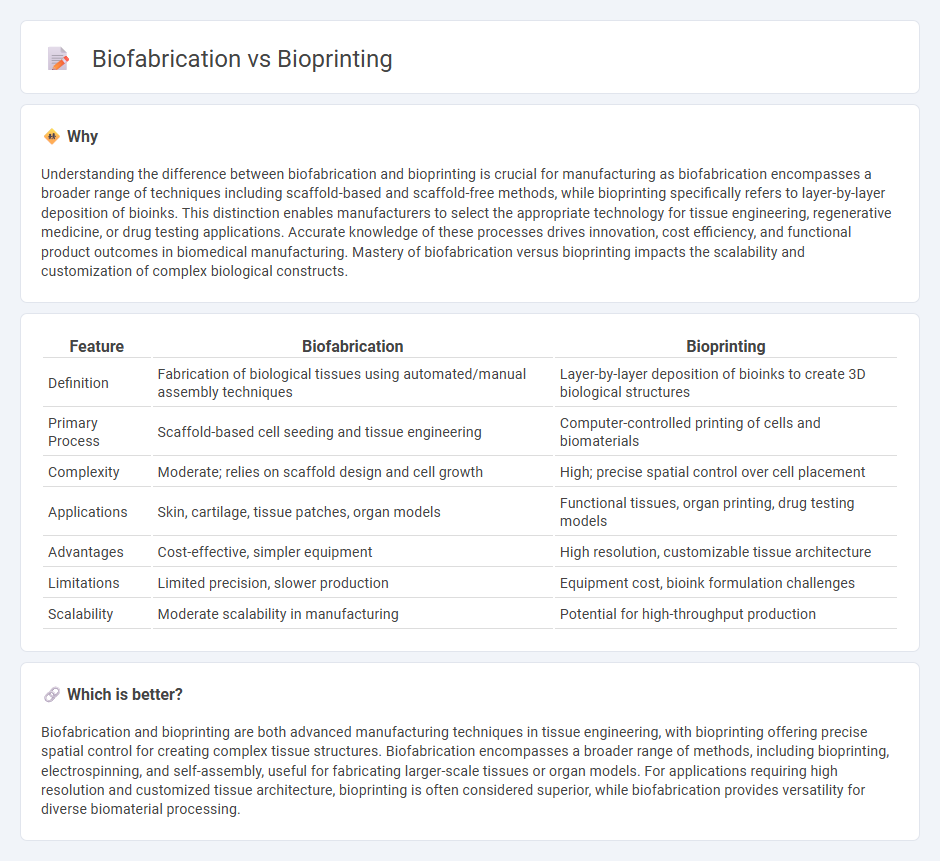

Understanding the difference between biofabrication and bioprinting is crucial for manufacturing as biofabrication encompasses a broader range of techniques including scaffold-based and scaffold-free methods, while bioprinting specifically refers to layer-by-layer deposition of bioinks. This distinction enables manufacturers to select the appropriate technology for tissue engineering, regenerative medicine, or drug testing applications. Accurate knowledge of these processes drives innovation, cost efficiency, and functional product outcomes in biomedical manufacturing. Mastery of biofabrication versus bioprinting impacts the scalability and customization of complex biological constructs.

Comparison Table

| Feature | Biofabrication | Bioprinting |

|---|---|---|

| Definition | Fabrication of biological tissues using automated/manual assembly techniques | Layer-by-layer deposition of bioinks to create 3D biological structures |

| Primary Process | Scaffold-based cell seeding and tissue engineering | Computer-controlled printing of cells and biomaterials |

| Complexity | Moderate; relies on scaffold design and cell growth | High; precise spatial control over cell placement |

| Applications | Skin, cartilage, tissue patches, organ models | Functional tissues, organ printing, drug testing models |

| Advantages | Cost-effective, simpler equipment | High resolution, customizable tissue architecture |

| Limitations | Limited precision, slower production | Equipment cost, bioink formulation challenges |

| Scalability | Moderate scalability in manufacturing | Potential for high-throughput production |

Which is better?

Biofabrication and bioprinting are both advanced manufacturing techniques in tissue engineering, with bioprinting offering precise spatial control for creating complex tissue structures. Biofabrication encompasses a broader range of methods, including bioprinting, electrospinning, and self-assembly, useful for fabricating larger-scale tissues or organ models. For applications requiring high resolution and customized tissue architecture, bioprinting is often considered superior, while biofabrication provides versatility for diverse biomaterial processing.

Connection

Biofabrication integrates bioprinting techniques to create complex, functional biological structures by layering living cells and biomaterials with precision. Bioprinting serves as a core manufacturing process within biofabrication, enabling the production of tissues and organs for medical applications. Together, these technologies revolutionize regenerative medicine by offering scalable, customizable solutions for tissue engineering and drug testing.

Key Terms

Scaffold

Bioprinting and biofabrication both focus on creating scaffolds that support tissue regeneration, but bioprinting uses precise layer-by-layer deposition of bioinks to build complex 3D structures, whereas biofabrication encompasses a broader range of techniques including electrospinning and cell sheet engineering. Scaffold materials typically include hydrogels, ceramics, and biodegradable polymers tailored for specific cellular environments and mechanical properties. Explore innovative scaffold designs and applications in regenerative medicine to understand their potential impact.

Bioink

Bioprinting utilizes precise layering techniques to deposit bioinks composed of living cells and biomaterials, enabling the creation of complex tissue structures with high spatial resolution. Biofabrication encompasses a broader range of methods, including bioprinting, aimed at fabricating biological constructs through the integration of bioinks, scaffolds, and biomolecules. Explore in-depth comparison of bioink formulations and their impact on tissue engineering outcomes to understand the nuances between these advanced approaches.

Tissue engineering

Bioprinting utilizes layer-by-layer deposition of biomaterials and living cells to create precise tissue constructs, while biofabrication encompasses a broader range of techniques including bioprinting, self-assembly, and scaffold-based methods to engineer complex tissue structures. In tissue engineering, bioprinting offers high spatial control and reproducibility for creating vascularized tissues, whereas biofabrication integrates multiple approaches to mimic native tissue architecture and functionality more effectively. Explore detailed comparisons and advancements in bioprinting and biofabrication to enhance tissue engineering applications.

Source and External Links

3D Bioprinting: Definition, History, How it Works, and Types | Xometry - 3D bioprinting is an early-stage technology that uses biological and bio-functional materials in additive manufacturing to create living tissue constructs and eventually organs for medical applications like patient implants and drug testing.

Bioprinting, explained simply - CELLINK - Bioprinting uses bioinks mixed with living cells and biomaterials to 3D print living tissue models layer-by-layer, offering advances in regenerative medicine, tissue engineering, drug discovery, and cosmetics.

3D bioprinting - Wikipedia - 3D bioprinting combines cells, growth factors, and biomaterials using layer-by-layer additive manufacturing to create tissue-like functional structures, with applications spanning tissue engineering, medical research, and environmental remediation.

dowidth.com

dowidth.com