Cloud manufacturing leverages internet-based platforms to enable scalable, flexible production by integrating distributed resources and real-time data analytics. Digital manufacturing focuses on using digital tools such as CAD, simulation, and automation to optimize product design and production processes within localized factory environments. Explore the distinct advantages and applications of cloud manufacturing and digital manufacturing to enhance operational efficiency and innovation.

Why it is important

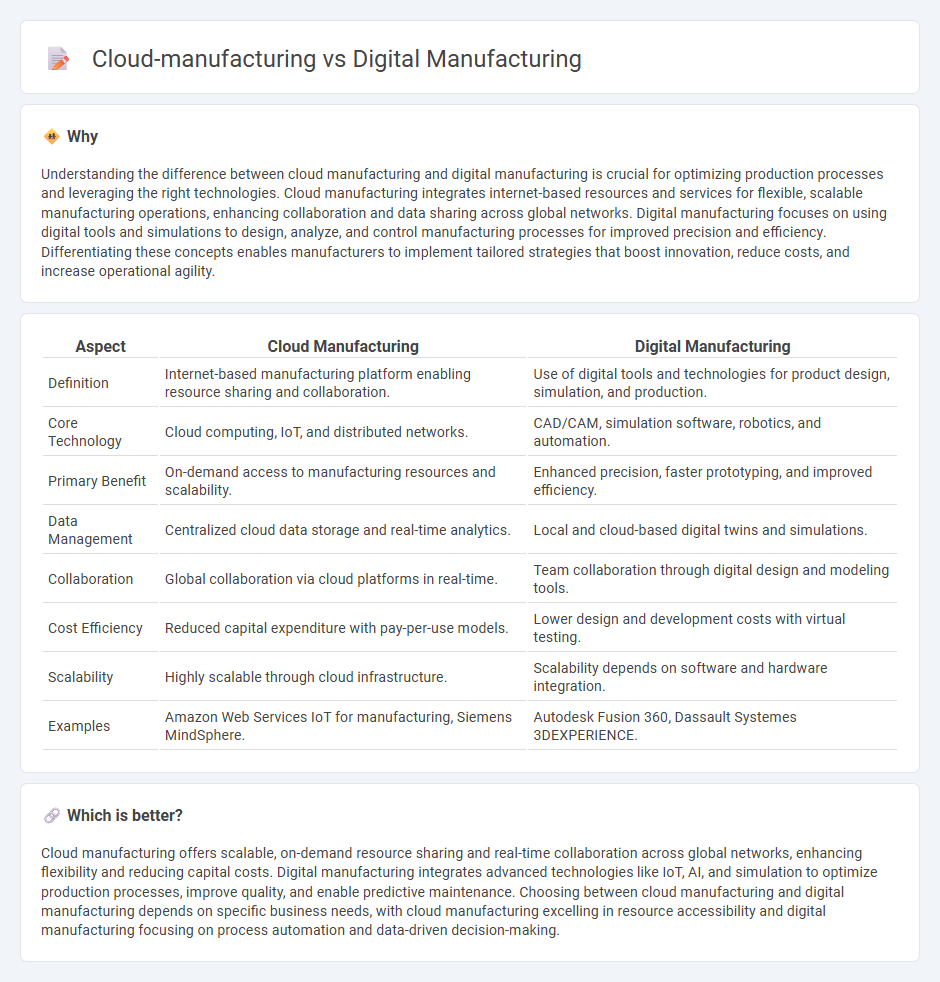

Understanding the difference between cloud manufacturing and digital manufacturing is crucial for optimizing production processes and leveraging the right technologies. Cloud manufacturing integrates internet-based resources and services for flexible, scalable manufacturing operations, enhancing collaboration and data sharing across global networks. Digital manufacturing focuses on using digital tools and simulations to design, analyze, and control manufacturing processes for improved precision and efficiency. Differentiating these concepts enables manufacturers to implement tailored strategies that boost innovation, reduce costs, and increase operational agility.

Comparison Table

| Aspect | Cloud Manufacturing | Digital Manufacturing |

|---|---|---|

| Definition | Internet-based manufacturing platform enabling resource sharing and collaboration. | Use of digital tools and technologies for product design, simulation, and production. |

| Core Technology | Cloud computing, IoT, and distributed networks. | CAD/CAM, simulation software, robotics, and automation. |

| Primary Benefit | On-demand access to manufacturing resources and scalability. | Enhanced precision, faster prototyping, and improved efficiency. |

| Data Management | Centralized cloud data storage and real-time analytics. | Local and cloud-based digital twins and simulations. |

| Collaboration | Global collaboration via cloud platforms in real-time. | Team collaboration through digital design and modeling tools. |

| Cost Efficiency | Reduced capital expenditure with pay-per-use models. | Lower design and development costs with virtual testing. |

| Scalability | Highly scalable through cloud infrastructure. | Scalability depends on software and hardware integration. |

| Examples | Amazon Web Services IoT for manufacturing, Siemens MindSphere. | Autodesk Fusion 360, Dassault Systemes 3DEXPERIENCE. |

Which is better?

Cloud manufacturing offers scalable, on-demand resource sharing and real-time collaboration across global networks, enhancing flexibility and reducing capital costs. Digital manufacturing integrates advanced technologies like IoT, AI, and simulation to optimize production processes, improve quality, and enable predictive maintenance. Choosing between cloud manufacturing and digital manufacturing depends on specific business needs, with cloud manufacturing excelling in resource accessibility and digital manufacturing focusing on process automation and data-driven decision-making.

Connection

Cloud manufacturing integrates cloud computing technologies with manufacturing processes, enabling real-time data sharing, remote monitoring, and scalable resource allocation. Digital manufacturing utilizes digital tools such as CAD, CAM, and simulation to design, analyze, and optimize production workflows. The connection lies in leveraging cloud infrastructure to enhance digital manufacturing capabilities, facilitating seamless collaboration, data storage, and process automation across distributed manufacturing environments.

Key Terms

Digital Twin

Digital manufacturing integrates advanced technologies like IoT and AI to optimize production processes, while cloud manufacturing leverages distributed cloud resources for scalability and real-time collaboration. Digital Twin technology plays a crucial role in both approaches by creating virtual replicas of physical assets, enabling predictive maintenance and process simulation. Explore how Digital Twin enhances efficiency and innovation in manufacturing by bridging digital and physical realms.

Cloud-Based MES (Manufacturing Execution System)

Cloud-based MES integrates manufacturing execution processes with real-time data analytics and remote accessibility, offering scalability and reduced IT infrastructure costs compared to traditional digital manufacturing systems. By leveraging cloud computing, it enables seamless production monitoring, improved resource management, and enhanced collaboration across geographically dispersed facilities. Explore how cloud-based MES transforms manufacturing operations by visiting our in-depth resource page.

Distributed Production

Digital manufacturing integrates advanced technologies such as IoT, AI, and robotics to optimize production processes within centralized facilities, enhancing precision and efficiency. Cloud manufacturing leverages cloud computing to enable distributed production by connecting multiple manufacturing units through the internet, facilitating resource sharing, scalability, and real-time collaboration across geographically dispersed sites. Explore the transformative impact of distributed production in cloud manufacturing to understand its potential for flexible and resilient manufacturing ecosystems.

Source and External Links

What Is Digital Manufacturing? Types & Applications | NetSuite - Digital manufacturing integrates digital technologies like IIoT, AI, and data analytics with physical production to optimize and automate manufacturing processes, enhancing product life cycle management, smart factory operations, and value-chain efficiency.

What is Digital Manufacturing? - Autodesk - Digital manufacturing uses digital tools to design, test, and produce goods, improving supply chain visibility, enabling sustainable manufacturing, and supporting technologies such as automation, robotics, 3D printing, and cloud computing for smart, responsive factories.

Digital Manufacturing: Definition and Examples | Coursera - Digital manufacturing employs computer systems to enhance machines and processes, reducing bottlenecks and costs; it is part of Industry 4.0, enabling efficiency, flexibility, and higher profitability through integrated digital tools and real-time analytics.

dowidth.com

dowidth.com