Closed-loop manufacturing integrates real-time feedback systems to continuously monitor and adjust production processes, enhancing precision and reducing waste. Batch manufacturing produces goods in specific quantities or groups, offering flexibility but often leading to variable product quality and longer lead times. Explore the key differences and benefits to determine the best approach for your manufacturing needs.

Why it is important

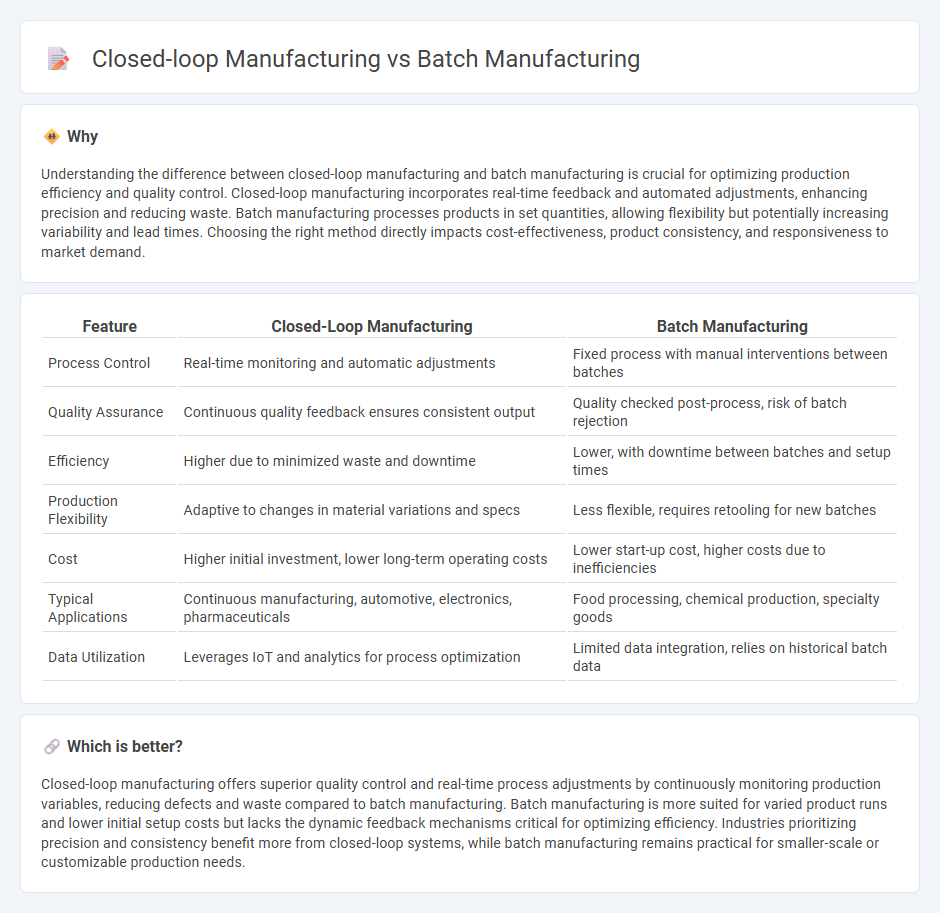

Understanding the difference between closed-loop manufacturing and batch manufacturing is crucial for optimizing production efficiency and quality control. Closed-loop manufacturing incorporates real-time feedback and automated adjustments, enhancing precision and reducing waste. Batch manufacturing processes products in set quantities, allowing flexibility but potentially increasing variability and lead times. Choosing the right method directly impacts cost-effectiveness, product consistency, and responsiveness to market demand.

Comparison Table

| Feature | Closed-Loop Manufacturing | Batch Manufacturing |

|---|---|---|

| Process Control | Real-time monitoring and automatic adjustments | Fixed process with manual interventions between batches |

| Quality Assurance | Continuous quality feedback ensures consistent output | Quality checked post-process, risk of batch rejection |

| Efficiency | Higher due to minimized waste and downtime | Lower, with downtime between batches and setup times |

| Production Flexibility | Adaptive to changes in material variations and specs | Less flexible, requires retooling for new batches |

| Cost | Higher initial investment, lower long-term operating costs | Lower start-up cost, higher costs due to inefficiencies |

| Typical Applications | Continuous manufacturing, automotive, electronics, pharmaceuticals | Food processing, chemical production, specialty goods |

| Data Utilization | Leverages IoT and analytics for process optimization | Limited data integration, relies on historical batch data |

Which is better?

Closed-loop manufacturing offers superior quality control and real-time process adjustments by continuously monitoring production variables, reducing defects and waste compared to batch manufacturing. Batch manufacturing is more suited for varied product runs and lower initial setup costs but lacks the dynamic feedback mechanisms critical for optimizing efficiency. Industries prioritizing precision and consistency benefit more from closed-loop systems, while batch manufacturing remains practical for smaller-scale or customizable production needs.

Connection

Closed-loop manufacturing integrates real-time feedback to continuously improve production quality and efficiency, while batch manufacturing divides production into discrete groups or lots. The connection lies in closed-loop systems enhancing batch processes by monitoring each batch's performance, enabling precise adjustments and quality control. This synergy results in minimized defects, optimized resource utilization, and increased consistency across manufacturing batches.

Key Terms

Production Flexibility

Batch manufacturing offers moderate production flexibility by producing goods in set quantities, enabling easier adjustments for demand fluctuations but with potential downtime between batches. Closed-loop manufacturing enhances flexibility through real-time monitoring and automated feedback systems, allowing continuous adaptation to production conditions and minimizing waste. Explore how these approaches impact efficiency and customization in modern factories.

Real-time Feedback

Batch manufacturing operates by processing products in distinct groups, often lacking immediate real-time feedback, which can delay adjustments and impact efficiency. Closed-loop manufacturing integrates continuous real-time feedback from sensors and automated control systems, enabling instant corrections to improve product quality and reduce waste. Explore how closed-loop systems enhance manufacturing precision and productivity through dynamic feedback mechanisms.

Quality Control

Batch manufacturing involves producing goods in designated quantities, allowing for quality control checks at specific stages to identify defects before proceeding. Closed-loop manufacturing continuously monitors production with real-time data feedback to immediately detect and correct quality issues, ensuring higher consistency and reducing waste. Explore how these manufacturing approaches impact quality control to choose the best fit for your production needs.

Source and External Links

What is Batch Production in Manufacturing? | SafetyCulture - Batch production is a manufacturing method where a group of identical products are produced together in one batch, with each batch moving through the production process sequentially and being inspected for quality at each stage.

What To Know About Batch Production: A Product Seller's Guide - This method involves manufacturing several identical or similar items at once, allowing for operational efficiency, easier quality control, and the flexibility to change product specifications between batches.

What is batch production in manufacturing? - OneAdvanced - In batch production, a set of identical products is made simultaneously, with each batch progressing through all stages of production together, enabling manufacturers to easily adjust product details and conduct quality checks between steps.

dowidth.com

dowidth.com