Circular manufacturing emphasizes sustainable production by minimizing waste and maximizing resource reuse throughout the product lifecycle, promoting environmental responsibility and cost efficiency. Agile manufacturing focuses on flexibility and rapid responsiveness to market changes, enabling businesses to adapt quickly to customer demands and technological advancements. Explore how these manufacturing approaches can transform your production strategy for better sustainability and competitiveness.

Why it is important

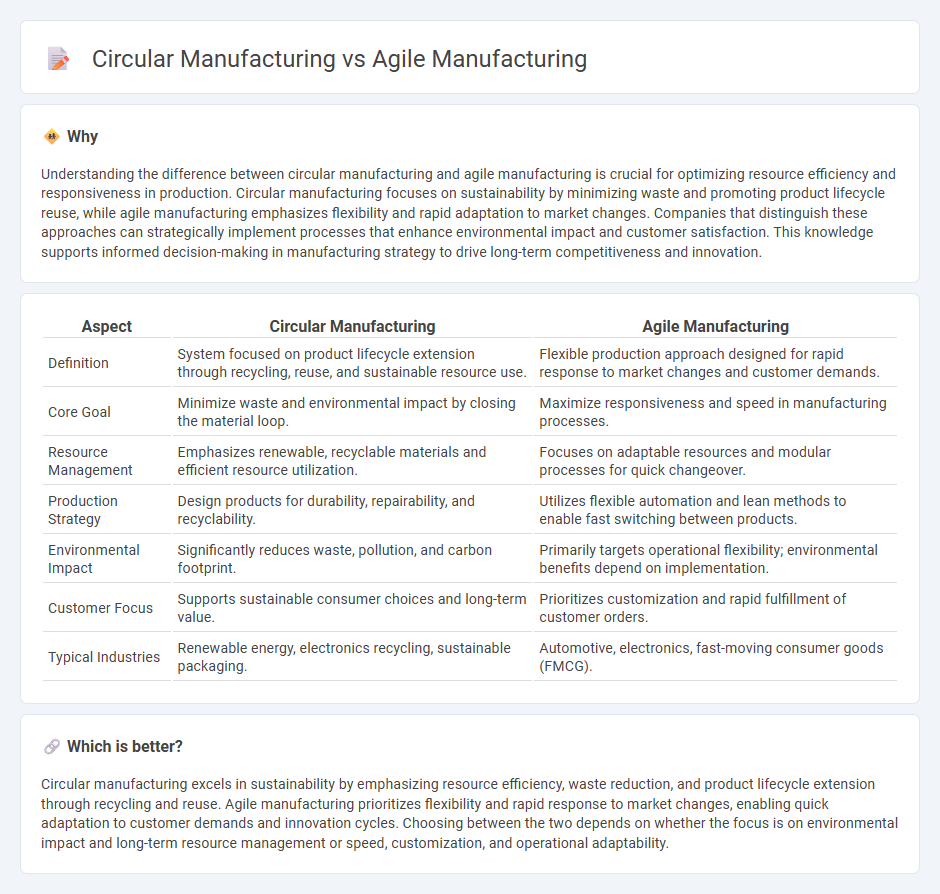

Understanding the difference between circular manufacturing and agile manufacturing is crucial for optimizing resource efficiency and responsiveness in production. Circular manufacturing focuses on sustainability by minimizing waste and promoting product lifecycle reuse, while agile manufacturing emphasizes flexibility and rapid adaptation to market changes. Companies that distinguish these approaches can strategically implement processes that enhance environmental impact and customer satisfaction. This knowledge supports informed decision-making in manufacturing strategy to drive long-term competitiveness and innovation.

Comparison Table

| Aspect | Circular Manufacturing | Agile Manufacturing |

|---|---|---|

| Definition | System focused on product lifecycle extension through recycling, reuse, and sustainable resource use. | Flexible production approach designed for rapid response to market changes and customer demands. |

| Core Goal | Minimize waste and environmental impact by closing the material loop. | Maximize responsiveness and speed in manufacturing processes. |

| Resource Management | Emphasizes renewable, recyclable materials and efficient resource utilization. | Focuses on adaptable resources and modular processes for quick changeover. |

| Production Strategy | Design products for durability, repairability, and recyclability. | Utilizes flexible automation and lean methods to enable fast switching between products. |

| Environmental Impact | Significantly reduces waste, pollution, and carbon footprint. | Primarily targets operational flexibility; environmental benefits depend on implementation. |

| Customer Focus | Supports sustainable consumer choices and long-term value. | Prioritizes customization and rapid fulfillment of customer orders. |

| Typical Industries | Renewable energy, electronics recycling, sustainable packaging. | Automotive, electronics, fast-moving consumer goods (FMCG). |

Which is better?

Circular manufacturing excels in sustainability by emphasizing resource efficiency, waste reduction, and product lifecycle extension through recycling and reuse. Agile manufacturing prioritizes flexibility and rapid response to market changes, enabling quick adaptation to customer demands and innovation cycles. Choosing between the two depends on whether the focus is on environmental impact and long-term resource management or speed, customization, and operational adaptability.

Connection

Circular manufacturing and agile manufacturing are connected through their mutual emphasis on efficiency and sustainability in production processes. Circular manufacturing focuses on minimizing waste and maximizing resource reuse, while agile manufacturing prioritizes flexibility and rapid response to market changes. Integrating these approaches enables companies to optimize resource management and swiftly adapt production, leading to sustainable and resilient manufacturing systems.

Key Terms

**Agile Manufacturing:**

Agile manufacturing emphasizes flexibility, speed, and responsiveness to rapidly changing market demands through modular production systems and advanced information technology integration. It prioritizes customization, efficient resource allocation, and reduced lead times, enabling companies to adapt quickly to product variations and customer preferences. Explore how agile manufacturing drives innovation and operational excellence in dynamic industries.

Flexibility

Agile manufacturing prioritizes flexibility by enabling rapid adaptation to market changes through modular processes and customizable production lines. Circular manufacturing emphasizes flexibility in resource utilization by designing products and systems that facilitate reuse, recycling, and waste reduction. Explore how these flexibility strategies optimize manufacturing efficiency and sustainability.

Rapid Response

Agile manufacturing emphasizes flexibility and quick adaptation to market demands, enabling rapid response through modular production lines and real-time data analytics. Circular manufacturing integrates sustainability by prioritizing resource efficiency, waste reduction, and product lifecycle extension, which can influence responsiveness by streamlining material reuse processes. Explore how combining agile and circular manufacturing strategies enhances rapid response while promoting eco-friendly production systems.

Source and External Links

What Is Agile Manufacturing? Lean vs. Agile - Agile manufacturing is a methodology focused on rapid response to customer needs, making speed and adaptability key competitive advantages for manufacturers, especially in regions with high labor costs and strong local markets.

Agile Manufacturing - Wikipedia - Agile manufacturing enables companies to respond swiftly and flexibly to market changes while maintaining quality and cost control, emphasizing adaptability and proactive responsiveness over traditional lean principles.

Agile Manufacturing Explained: What, How, and Why - Agile manufacturing leverages modern technologies like 3D printing and real-time scheduling software to create flexible, adaptable production processes that can quickly meet changing customer demands.

dowidth.com

dowidth.com