Collaborative robots enhance manufacturing efficiency by working alongside human operators, reducing repetitive strain and increasing precision compared to manual workstations. Manual workstations rely heavily on human skill and endurance, often leading to variable output quality and slower production rates. Discover how integrating collaborative robots can revolutionize your manufacturing processes.

Why it is important

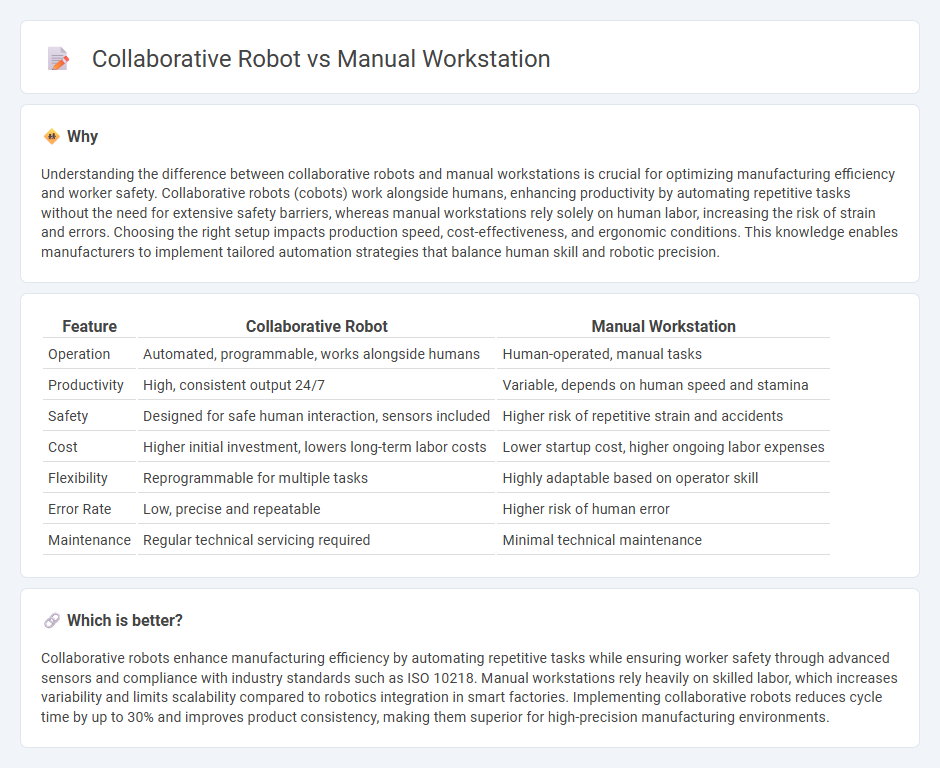

Understanding the difference between collaborative robots and manual workstations is crucial for optimizing manufacturing efficiency and worker safety. Collaborative robots (cobots) work alongside humans, enhancing productivity by automating repetitive tasks without the need for extensive safety barriers, whereas manual workstations rely solely on human labor, increasing the risk of strain and errors. Choosing the right setup impacts production speed, cost-effectiveness, and ergonomic conditions. This knowledge enables manufacturers to implement tailored automation strategies that balance human skill and robotic precision.

Comparison Table

| Feature | Collaborative Robot | Manual Workstation |

|---|---|---|

| Operation | Automated, programmable, works alongside humans | Human-operated, manual tasks |

| Productivity | High, consistent output 24/7 | Variable, depends on human speed and stamina |

| Safety | Designed for safe human interaction, sensors included | Higher risk of repetitive strain and accidents |

| Cost | Higher initial investment, lowers long-term labor costs | Lower startup cost, higher ongoing labor expenses |

| Flexibility | Reprogrammable for multiple tasks | Highly adaptable based on operator skill |

| Error Rate | Low, precise and repeatable | Higher risk of human error |

| Maintenance | Regular technical servicing required | Minimal technical maintenance |

Which is better?

Collaborative robots enhance manufacturing efficiency by automating repetitive tasks while ensuring worker safety through advanced sensors and compliance with industry standards such as ISO 10218. Manual workstations rely heavily on skilled labor, which increases variability and limits scalability compared to robotics integration in smart factories. Implementing collaborative robots reduces cycle time by up to 30% and improves product consistency, making them superior for high-precision manufacturing environments.

Connection

Collaborative robots (cobots) seamlessly integrate with manual workstations to enhance manufacturing efficiency by automating repetitive or hazardous tasks while enabling human operators to focus on complex, value-added activities. Sensors and real-time communication systems allow cobots to adapt to human movements, ensuring safety and fluid cooperation on the production floor. This synergy between cobots and manual workstations leads to increased productivity, reduced ergonomic risks, and higher quality output in manufacturing processes.

Key Terms

Ergonomics

Manual workstations often expose workers to repetitive motion and awkward postures, increasing the risk of musculoskeletal disorders. Collaborative robots (cobots) can assist by handling repetitive or strenuous tasks, reducing physical strain and enhancing overall workplace ergonomics. Explore how integrating cobots improves worker safety and productivity in modern industrial settings.

Human-robot interaction

Manual workstations rely on direct human operation, emphasizing ergonomic design and intuitive tool access to enhance productivity and reduce fatigue. Collaborative robots (cobots) integrate advanced sensors and AI to work safely alongside humans, improving precision and task efficiency without compromising worker safety. Explore the latest advancements in human-robot interaction to optimize your production environment.

Productivity

Manual workstations rely heavily on human labor, limiting output speed and consistency compared to collaborative robots, which enhance productivity through automation and precise task execution. Collaborative robots integrate seamlessly with human operators, increasing efficiency by reducing repetitive strain and minimizing errors in manufacturing environments. Explore how implementing collaborative robots can transform your production workflow and boost overall productivity.

Source and External Links

Manual workstation basic - Honsel - Semi-automatic manual workstation featuring ergonomic height-adjustable surfaces, a manual turning unit, DMC scanner, and LED lighting for efficient processing of fasteners.

BOSTONtec Manual Height Adjustable Workstation, 30" D X 60" W - Manual height adjustable workstation designed for single-shift, single operator use, with a cantilevered leg style supporting seated to standing adjustments.

Standard Manual Adjustable Workstations | Marketlab - Workstations on lockable caster wheels allow mobility and stability, featuring laminate work surfaces and assembled bases for versatile manual adjustment.

dowidth.com

dowidth.com