Zero Defect Manufacturing focuses on eliminating defects through rigorous quality control and error-proofing techniques, ensuring products meet exact specifications. Lean Manufacturing emphasizes waste reduction and process efficiency to optimize production flow and minimize costs while maintaining quality. Explore the key differences and benefits of both approaches to improve your manufacturing strategy.

Why it is important

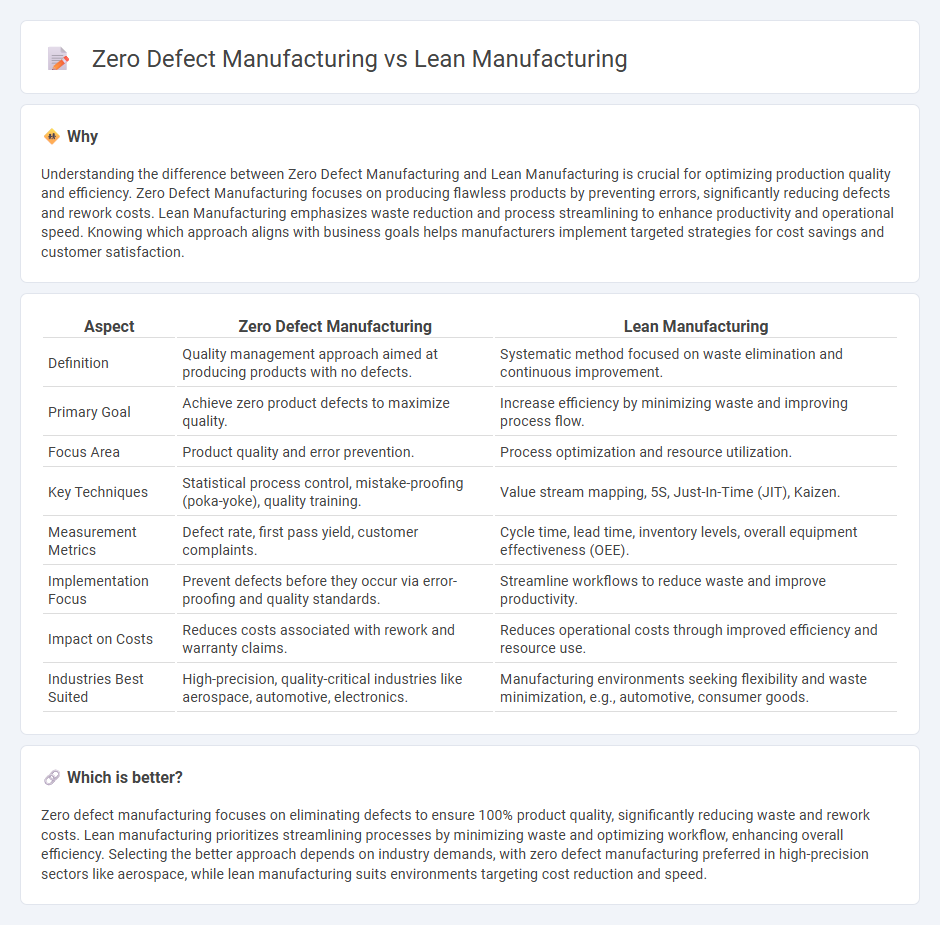

Understanding the difference between Zero Defect Manufacturing and Lean Manufacturing is crucial for optimizing production quality and efficiency. Zero Defect Manufacturing focuses on producing flawless products by preventing errors, significantly reducing defects and rework costs. Lean Manufacturing emphasizes waste reduction and process streamlining to enhance productivity and operational speed. Knowing which approach aligns with business goals helps manufacturers implement targeted strategies for cost savings and customer satisfaction.

Comparison Table

| Aspect | Zero Defect Manufacturing | Lean Manufacturing |

|---|---|---|

| Definition | Quality management approach aimed at producing products with no defects. | Systematic method focused on waste elimination and continuous improvement. |

| Primary Goal | Achieve zero product defects to maximize quality. | Increase efficiency by minimizing waste and improving process flow. |

| Focus Area | Product quality and error prevention. | Process optimization and resource utilization. |

| Key Techniques | Statistical process control, mistake-proofing (poka-yoke), quality training. | Value stream mapping, 5S, Just-In-Time (JIT), Kaizen. |

| Measurement Metrics | Defect rate, first pass yield, customer complaints. | Cycle time, lead time, inventory levels, overall equipment effectiveness (OEE). |

| Implementation Focus | Prevent defects before they occur via error-proofing and quality standards. | Streamline workflows to reduce waste and improve productivity. |

| Impact on Costs | Reduces costs associated with rework and warranty claims. | Reduces operational costs through improved efficiency and resource use. |

| Industries Best Suited | High-precision, quality-critical industries like aerospace, automotive, electronics. | Manufacturing environments seeking flexibility and waste minimization, e.g., automotive, consumer goods. |

Which is better?

Zero defect manufacturing focuses on eliminating defects to ensure 100% product quality, significantly reducing waste and rework costs. Lean manufacturing prioritizes streamlining processes by minimizing waste and optimizing workflow, enhancing overall efficiency. Selecting the better approach depends on industry demands, with zero defect manufacturing preferred in high-precision sectors like aerospace, while lean manufacturing suits environments targeting cost reduction and speed.

Connection

Zero defect manufacturing and Lean Manufacturing are interconnected through their shared focus on waste reduction and quality improvement in production processes. Lean Manufacturing aims to eliminate non-value-added activities, streamlining operations and minimizing defects, while Zero defect manufacturing emphasizes preventing errors by implementing rigorous quality control and continuous improvement methods. Together, these methodologies enhance efficiency, reduce costs, and ensure the delivery of high-quality products.

Key Terms

Waste Reduction (Lean Manufacturing)

Lean Manufacturing emphasizes continuous waste reduction by eliminating non-value-added activities, optimizing processes, and enhancing resource efficiency to minimize costs and improve productivity. Zero Defect Manufacturing aims at achieving flawless production by implementing stringent quality controls and error-proofing techniques to prevent defects from occurring. Explore detailed strategies in waste reduction and quality assurance to enhance your manufacturing processes.

Continuous Improvement (Lean Manufacturing)

Lean Manufacturing emphasizes continuous improvement by systematically eliminating waste and optimizing processes to enhance efficiency and product quality. Zero Defect Manufacturing focuses on achieving perfect products by preventing defects through rigorous quality control and error-proofing techniques. Explore how integrating these methodologies can drive superior operational performance and customer satisfaction.

Defect Prevention (Zero Defect Manufacturing)

Lean Manufacturing emphasizes waste reduction and process efficiency to enhance production flow and minimize defects indirectly, while Zero Defect Manufacturing specifically targets defect prevention to achieve near-perfect quality in every product. Zero Defect Manufacturing employs rigorous quality control techniques, extensive process audits, and operator training to eliminate errors at the source, ensuring consistent product reliability and customer satisfaction. Explore the critical strategies and benefits of defect prevention by diving deeper into Zero Defect Manufacturing principles.

Source and External Links

Lean manufacturing - Wikipedia - Lean manufacturing is a production method focused on reducing times within the production system and eliminating waste to maximize efficiency and productivity.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing is a methodology that minimizes waste while maximizing productivity, often associated with the Toyota Production System.

What is Lean Manufacturing and the 5 Principles Used? - TWI - Lean manufacturing involves streamlining processes to minimize waste and maximize productivity, guided by five core principles: value, value stream, flow, pull, and perfection.

dowidth.com

dowidth.com