Industrial symbiosis leverages by-products and waste streams from multiple manufacturing processes to create a network of resource exchange, significantly reducing raw material consumption and environmental impact. Zero waste manufacturing focuses on designing production systems and processes to eliminate waste generation entirely throughout the product lifecycle. Explore how these innovative approaches redefine sustainability in manufacturing.

Why it is important

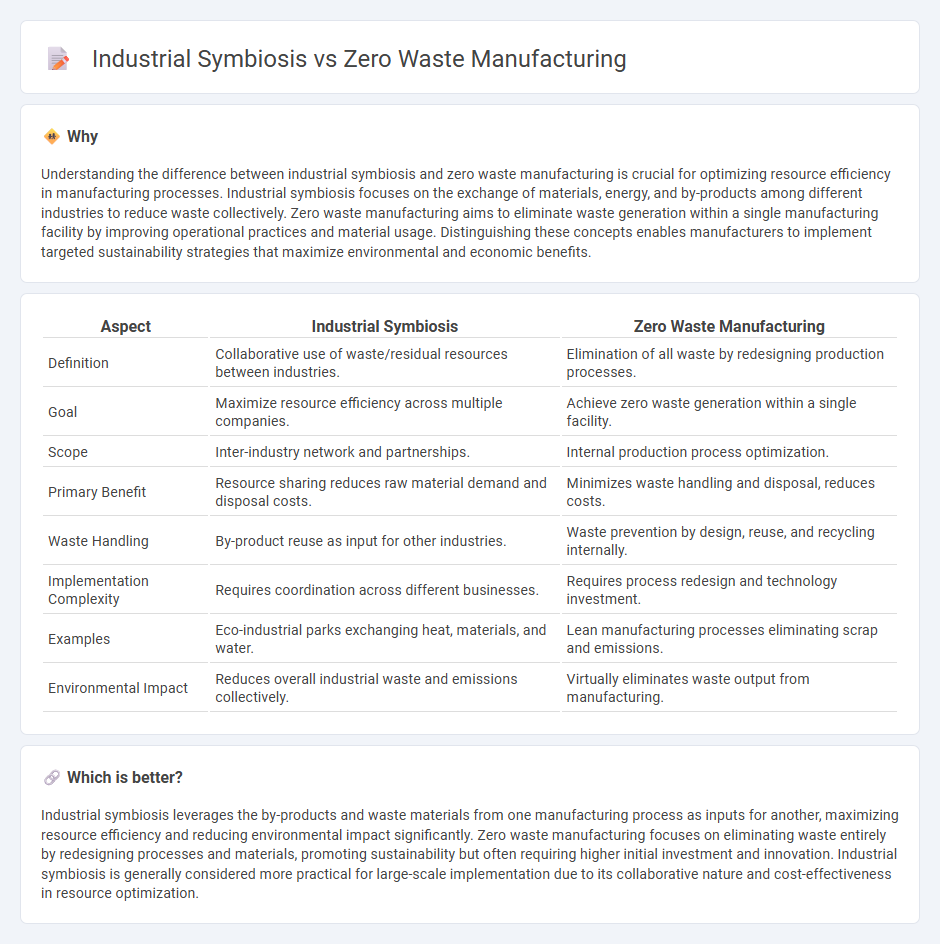

Understanding the difference between industrial symbiosis and zero waste manufacturing is crucial for optimizing resource efficiency in manufacturing processes. Industrial symbiosis focuses on the exchange of materials, energy, and by-products among different industries to reduce waste collectively. Zero waste manufacturing aims to eliminate waste generation within a single manufacturing facility by improving operational practices and material usage. Distinguishing these concepts enables manufacturers to implement targeted sustainability strategies that maximize environmental and economic benefits.

Comparison Table

| Aspect | Industrial Symbiosis | Zero Waste Manufacturing |

|---|---|---|

| Definition | Collaborative use of waste/residual resources between industries. | Elimination of all waste by redesigning production processes. |

| Goal | Maximize resource efficiency across multiple companies. | Achieve zero waste generation within a single facility. |

| Scope | Inter-industry network and partnerships. | Internal production process optimization. |

| Primary Benefit | Resource sharing reduces raw material demand and disposal costs. | Minimizes waste handling and disposal, reduces costs. |

| Waste Handling | By-product reuse as input for other industries. | Waste prevention by design, reuse, and recycling internally. |

| Implementation Complexity | Requires coordination across different businesses. | Requires process redesign and technology investment. |

| Examples | Eco-industrial parks exchanging heat, materials, and water. | Lean manufacturing processes eliminating scrap and emissions. |

| Environmental Impact | Reduces overall industrial waste and emissions collectively. | Virtually eliminates waste output from manufacturing. |

Which is better?

Industrial symbiosis leverages the by-products and waste materials from one manufacturing process as inputs for another, maximizing resource efficiency and reducing environmental impact significantly. Zero waste manufacturing focuses on eliminating waste entirely by redesigning processes and materials, promoting sustainability but often requiring higher initial investment and innovation. Industrial symbiosis is generally considered more practical for large-scale implementation due to its collaborative nature and cost-effectiveness in resource optimization.

Connection

Industrial symbiosis enhances zero waste manufacturing by facilitating the exchange of materials, energy, and resources between different industries, minimizing waste generation. This collaborative approach transforms by-products from one process into valuable inputs for another, optimizing resource efficiency and reducing environmental impact. Integrating these strategies accelerates sustainable production, driving circular economy principles within manufacturing ecosystems.

Key Terms

**Zero Waste Manufacturing:**

Zero waste manufacturing aims to eliminate waste by redesigning production processes to reuse all materials, minimizing landfill contributions and resource consumption. This method integrates strategies such as material recycling, efficient resource use, and product lifecycle analysis to create sustainable manufacturing ecosystems. Discover how zero waste manufacturing can transform industrial practices for a greener future.

Closed-loop systems

Zero waste manufacturing emphasizes the elimination of waste through product design, process optimization, and material reuse, creating closed-loop systems that minimize environmental impact. Industrial symbiosis facilitates resource sharing between different industries, where the by-products of one process serve as the inputs for another, enabling efficient closed-loop cycles across multiple sectors. Explore further to understand how these approaches transform sustainability in industrial ecosystems.

Waste minimization

Zero waste manufacturing emphasizes designing processes to eliminate waste generation entirely, focusing on resource efficiency and reuse within production cycles. Industrial symbiosis involves collaborative waste exchanges between industries, converting one process's byproducts into valuable inputs for another, effectively minimizing waste at an ecosystem level. Discover more about how these strategies complement each other to achieve sustainable waste minimization goals.

Source and External Links

Can manufacturing truly achieve zero waste? - Zero waste manufacturing hinges on strategies like lean manufacturing, circular economy practices (e.g., design for recyclability, product-as-a-service, industrial symbiosis), focusing on reducing, reusing, and recycling materials to minimize waste and resource consumption throughout production.

Zero Waste Manufacturing - This approach improves sustainability and operational efficiency by minimizing waste generation, reusing and recycling materials, aligning with environmental regulations, reducing costs, creating new business opportunities, and enhancing brand image.

What is Zero-Waste Manufacturing? - Zero waste manufacturing encompasses sustainable practices along the entire product lifecycle and supply chain, including extended producer responsibility (EPR), machinery innovations like on-demand packaging, and product designs that facilitate reuse, repair, and recycling.

dowidth.com

dowidth.com