Circular manufacturing focuses on designing products and processes that minimize waste by reusing materials and recovering resources throughout the production cycle, promoting sustainability and reducing environmental impact. Continuous manufacturing involves uninterrupted production flows that enhance efficiency, consistency, and scalability by maintaining a constant input and output rate in manufacturing processes. Explore the distinctions and benefits of circular manufacturing versus continuous manufacturing to optimize your production strategy.

Why it is important

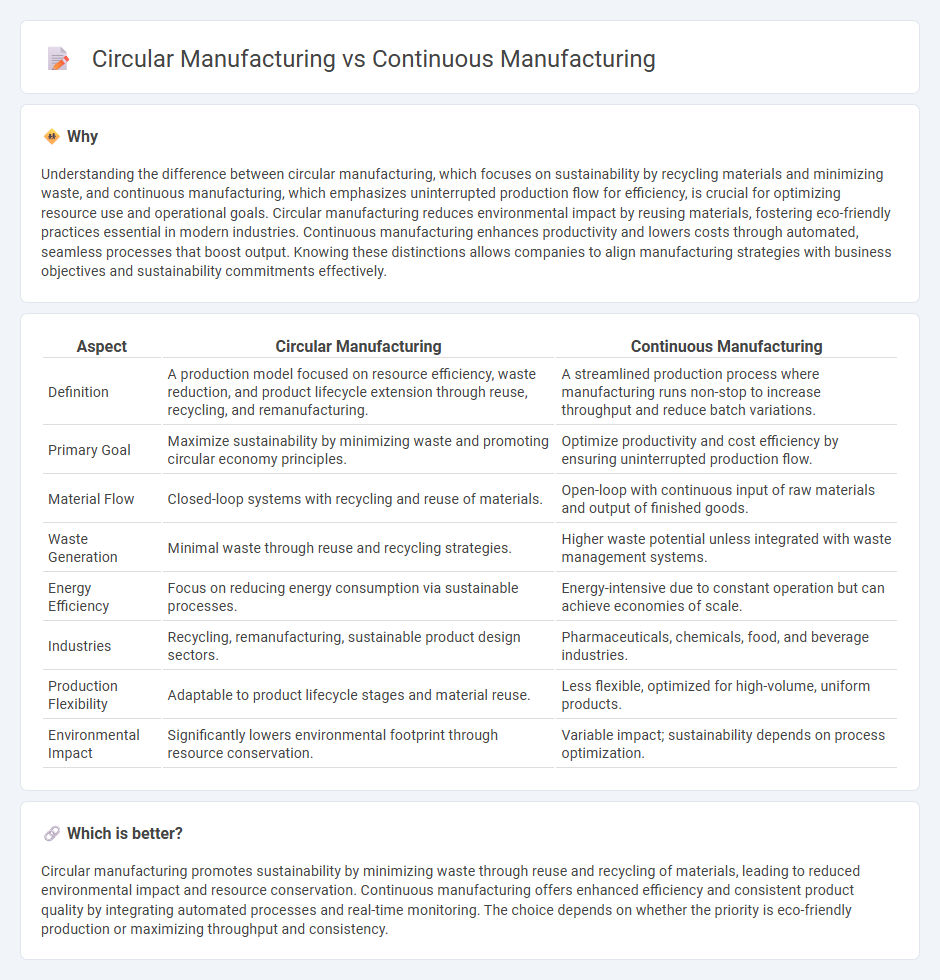

Understanding the difference between circular manufacturing, which focuses on sustainability by recycling materials and minimizing waste, and continuous manufacturing, which emphasizes uninterrupted production flow for efficiency, is crucial for optimizing resource use and operational goals. Circular manufacturing reduces environmental impact by reusing materials, fostering eco-friendly practices essential in modern industries. Continuous manufacturing enhances productivity and lowers costs through automated, seamless processes that boost output. Knowing these distinctions allows companies to align manufacturing strategies with business objectives and sustainability commitments effectively.

Comparison Table

| Aspect | Circular Manufacturing | Continuous Manufacturing |

|---|---|---|

| Definition | A production model focused on resource efficiency, waste reduction, and product lifecycle extension through reuse, recycling, and remanufacturing. | A streamlined production process where manufacturing runs non-stop to increase throughput and reduce batch variations. |

| Primary Goal | Maximize sustainability by minimizing waste and promoting circular economy principles. | Optimize productivity and cost efficiency by ensuring uninterrupted production flow. |

| Material Flow | Closed-loop systems with recycling and reuse of materials. | Open-loop with continuous input of raw materials and output of finished goods. |

| Waste Generation | Minimal waste through reuse and recycling strategies. | Higher waste potential unless integrated with waste management systems. |

| Energy Efficiency | Focus on reducing energy consumption via sustainable processes. | Energy-intensive due to constant operation but can achieve economies of scale. |

| Industries | Recycling, remanufacturing, sustainable product design sectors. | Pharmaceuticals, chemicals, food, and beverage industries. |

| Production Flexibility | Adaptable to product lifecycle stages and material reuse. | Less flexible, optimized for high-volume, uniform products. |

| Environmental Impact | Significantly lowers environmental footprint through resource conservation. | Variable impact; sustainability depends on process optimization. |

Which is better?

Circular manufacturing promotes sustainability by minimizing waste through reuse and recycling of materials, leading to reduced environmental impact and resource conservation. Continuous manufacturing offers enhanced efficiency and consistent product quality by integrating automated processes and real-time monitoring. The choice depends on whether the priority is eco-friendly production or maximizing throughput and consistency.

Connection

Circular manufacturing integrates waste reduction and resource reuse into production processes, promoting sustainability and efficiency. Continuous manufacturing enhances these goals by maintaining uninterrupted production flows, reducing material waste and energy consumption. Together, they optimize resource utilization, lower environmental impact, and improve overall manufacturing productivity.

Key Terms

**Continuous Manufacturing:**

Continuous manufacturing involves the nonstop production of goods using automated processes that enhance efficiency and reduce downtime, often applied in pharmaceuticals, chemicals, and food industries. This method improves product consistency, lowers operational costs, and accelerates time-to-market by integrating real-time monitoring and control systems. Explore more to understand how continuous manufacturing drives innovation and sustainability in modern production.

Automation

Continuous manufacturing integrates automation to streamline production lines by maintaining a consistent flow of materials, reducing downtime, and improving efficiency through real-time monitoring and control systems. Circular manufacturing leverages automation to enhance resource recovery, optimize waste reduction, and facilitate product reuse and recycling within closed-loop systems. Explore how automation technologies drive sustainability and efficiency in both manufacturing paradigms.

Real-time Monitoring

Continuous manufacturing employs real-time monitoring systems to ensure consistent product quality and operational efficiency by collecting and analyzing data throughout the production process. Circular manufacturing integrates real-time monitoring to track material flows, optimize resource use, and reduce waste, supporting sustainable and closed-loop production cycles. Explore how advanced real-time monitoring technologies enhance both manufacturing approaches for improved productivity and sustainability.

Source and External Links

What Is Continuous Manufacturing and How To Do It - Katana Cloud Inventory - Continuous manufacturing is a 24/7 production process that transforms raw materials--such as gases, liquids, powders, or slurries--into finished products in a single, uninterrupted movement, commonly used in industries like oil refining and pharmaceuticals.

Continuous Manufacturing: Batch to the Future - This method streamlines drug production by integrating all steps into a single, continuous line, reducing human error, shortening lead times, and offering more flexible batch size control compared to traditional batch manufacturing.

Continuous production - Wikipedia - Continuous production operates nearly nonstop, often 24/7 with only occasional shutdowns for maintenance, and is characterized by materials constantly moving through chemical reactions or mechanical/heat treatments, contrasting with batch or job production methods.

dowidth.com

dowidth.com