Biofabrication leverages living cells and biomaterials to create complex, functional tissues with precise structural and biological properties. Forming involves shaping materials, typically metals or plastics, through mechanical processes like molding, casting, or stamping to achieve desired physical forms. Explore the distinct advantages and applications of biofabrication and forming in modern manufacturing.

Why it is important

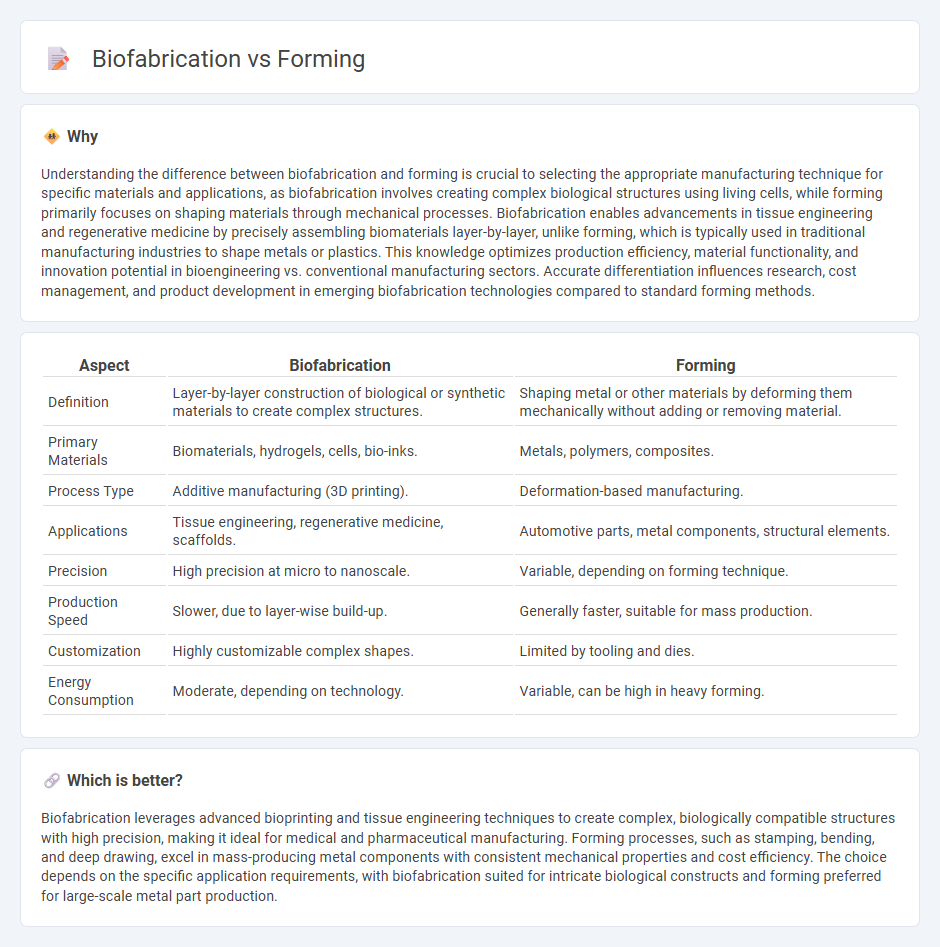

Understanding the difference between biofabrication and forming is crucial to selecting the appropriate manufacturing technique for specific materials and applications, as biofabrication involves creating complex biological structures using living cells, while forming primarily focuses on shaping materials through mechanical processes. Biofabrication enables advancements in tissue engineering and regenerative medicine by precisely assembling biomaterials layer-by-layer, unlike forming, which is typically used in traditional manufacturing industries to shape metals or plastics. This knowledge optimizes production efficiency, material functionality, and innovation potential in bioengineering vs. conventional manufacturing sectors. Accurate differentiation influences research, cost management, and product development in emerging biofabrication technologies compared to standard forming methods.

Comparison Table

| Aspect | Biofabrication | Forming |

|---|---|---|

| Definition | Layer-by-layer construction of biological or synthetic materials to create complex structures. | Shaping metal or other materials by deforming them mechanically without adding or removing material. |

| Primary Materials | Biomaterials, hydrogels, cells, bio-inks. | Metals, polymers, composites. |

| Process Type | Additive manufacturing (3D printing). | Deformation-based manufacturing. |

| Applications | Tissue engineering, regenerative medicine, scaffolds. | Automotive parts, metal components, structural elements. |

| Precision | High precision at micro to nanoscale. | Variable, depending on forming technique. |

| Production Speed | Slower, due to layer-wise build-up. | Generally faster, suitable for mass production. |

| Customization | Highly customizable complex shapes. | Limited by tooling and dies. |

| Energy Consumption | Moderate, depending on technology. | Variable, can be high in heavy forming. |

Which is better?

Biofabrication leverages advanced bioprinting and tissue engineering techniques to create complex, biologically compatible structures with high precision, making it ideal for medical and pharmaceutical manufacturing. Forming processes, such as stamping, bending, and deep drawing, excel in mass-producing metal components with consistent mechanical properties and cost efficiency. The choice depends on the specific application requirements, with biofabrication suited for intricate biological constructs and forming preferred for large-scale metal part production.

Connection

Biofabrication integrates advanced forming techniques such as extrusion, molding, and 3D bioprinting to create complex biological structures with precise control over shape and composition. Forming processes in biofabrication enable the layering, shaping, and assembly of biomaterials, facilitating tissue engineering and regenerative medicine applications. This synergy enhances manufacturing capabilities for producing biologically functional materials with high structural fidelity.

Key Terms

Deformation

Deformation behavior significantly differs between forming and biofabrication processes, with forming often involving plastic deformation of metals or polymers under mechanical stress, whereas biofabrication typically manages biomechanical properties in living tissues or hydrogels to maintain structural integrity. The control of deformation in biofabrication enables precise shaping and functionality of bioprinted tissues, critical for regenerative medicine and tissue engineering applications. Explore more about deformation mechanics and their impact on advanced manufacturing techniques.

Cell-laden scaffolds

Cell-laden scaffolds in biofabrication leverage advanced techniques like extrusion-based bioprinting to create highly precise, reproducible tissue constructs with embedded living cells, promoting enhanced cell viability and tissue integration. Forming methods typically involve traditional scaffold fabrication followed by cell seeding, which may result in less uniform cell distribution and limited control over microarchitecture. Explore the latest advancements in cell-laden scaffold fabrication to understand their impact on tissue engineering and regenerative medicine.

Additive manufacturing

Additive manufacturing, a key technology in forming and biofabrication, enables layer-by-layer material deposition to create complex structures with precise control over geometry and material properties. In biofabrication, additive manufacturing facilitates the production of biocompatible scaffolds and tissue models by integrating living cells and biomaterials. Explore further innovations and applications in additive manufacturing within forming and biofabrication sectors.

Source and External Links

Forming (metalworking) - Wikipedia - Forming is the mechanical reshaping of metal parts through plastic deformation without adding or removing material, keeping the mass unchanged, typically using very high loads and heavy machinery.

FORMING definition in American English - Collins Dictionary - Forming refers to the process of changing the shape of a partly finished product, like sheet metal, by plastic deformation without removing material.

Forging vs Forming in Metalworking: What's the Difference? - Forming is a metalworking process that changes the shape of a workpiece solely by mechanical deformation, involving compressive or tensile stresses, unlike forging that uses pressurized blows.

dowidth.com

dowidth.com