Smart dust technology consists of tiny, wireless sensors that monitor manufacturing environments at a granular level, enabling real-time data collection on temperature, vibration, and chemical changes. Machine vision systems utilize cameras and image processing algorithms to perform quality inspections, defect detection, and automation tasks on production lines with high precision. Explore how integrating smart dust and machine vision transforms manufacturing efficiency and accuracy.

Why it is important

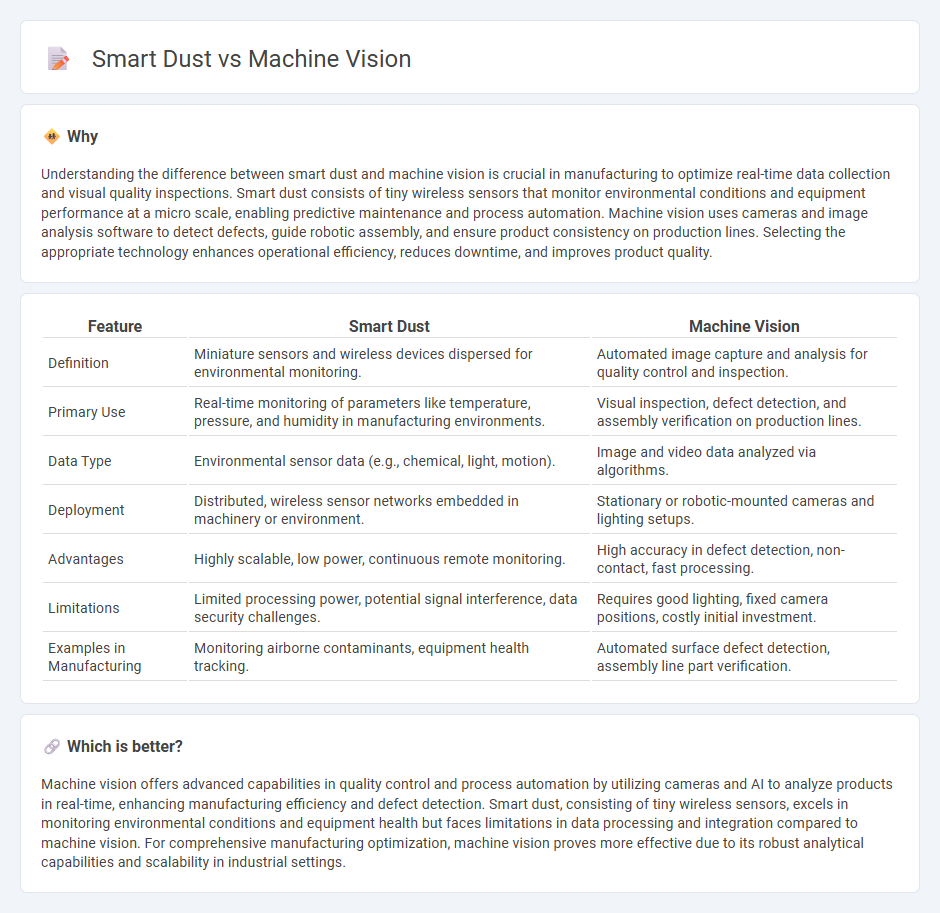

Understanding the difference between smart dust and machine vision is crucial in manufacturing to optimize real-time data collection and visual quality inspections. Smart dust consists of tiny wireless sensors that monitor environmental conditions and equipment performance at a micro scale, enabling predictive maintenance and process automation. Machine vision uses cameras and image analysis software to detect defects, guide robotic assembly, and ensure product consistency on production lines. Selecting the appropriate technology enhances operational efficiency, reduces downtime, and improves product quality.

Comparison Table

| Feature | Smart Dust | Machine Vision |

|---|---|---|

| Definition | Miniature sensors and wireless devices dispersed for environmental monitoring. | Automated image capture and analysis for quality control and inspection. |

| Primary Use | Real-time monitoring of parameters like temperature, pressure, and humidity in manufacturing environments. | Visual inspection, defect detection, and assembly verification on production lines. |

| Data Type | Environmental sensor data (e.g., chemical, light, motion). | Image and video data analyzed via algorithms. |

| Deployment | Distributed, wireless sensor networks embedded in machinery or environment. | Stationary or robotic-mounted cameras and lighting setups. |

| Advantages | Highly scalable, low power, continuous remote monitoring. | High accuracy in defect detection, non-contact, fast processing. |

| Limitations | Limited processing power, potential signal interference, data security challenges. | Requires good lighting, fixed camera positions, costly initial investment. |

| Examples in Manufacturing | Monitoring airborne contaminants, equipment health tracking. | Automated surface defect detection, assembly line part verification. |

Which is better?

Machine vision offers advanced capabilities in quality control and process automation by utilizing cameras and AI to analyze products in real-time, enhancing manufacturing efficiency and defect detection. Smart dust, consisting of tiny wireless sensors, excels in monitoring environmental conditions and equipment health but faces limitations in data processing and integration compared to machine vision. For comprehensive manufacturing optimization, machine vision proves more effective due to its robust analytical capabilities and scalability in industrial settings.

Connection

Smart dust and machine vision are connected through their shared ability to enhance manufacturing processes by providing real-time data collection and visual monitoring. Smart dust sensors can be deployed across production lines to gather environmental and operational metrics, while machine vision systems analyze visual data to detect defects and ensure quality control. Together, they enable predictive maintenance, improve efficiency, and reduce downtime in industrial manufacturing environments.

Key Terms

Image Processing

Machine vision systems leverage advanced image processing algorithms to analyze visual data for applications such as quality control and object recognition, delivering high-resolution and real-time insights. Smart dust, consisting of tiny sensors with limited processing power, relies on basic image capture and minimal data transmission, prioritizing environmental monitoring over complex image analysis. Explore the evolving technologies and their distinct capabilities in image processing to understand their optimal use cases.

Microelectromechanical Systems (MEMS)

Machine vision leverages advanced imaging sensors and MEMS-based micro-mirrors to enhance real-time object detection and quality inspection in automated manufacturing. Smart dust relies on MEMS technology to create tiny, wireless sensor networks capable of environmental monitoring and data collection at a microscale level. Explore the latest innovations in MEMS that drive machine vision and smart dust applications to understand their impact on the future of sensing technologies.

Wireless Sensor Networks

Machine vision systems employ high-resolution cameras and image processing algorithms to analyze visual information in real time, making them ideal for applications in industrial automation and quality control within Wireless Sensor Networks (WSNs). Smart dust consists of microscopic sensor nodes capable of sensing, computing, and communicating wirelessly, offering unparalleled scalability and deployment flexibility in WSN environments for monitoring physical parameters. Explore the latest advancements in Wireless Sensor Networks to understand how integrating machine vision and smart dust can revolutionize data collection and analysis.

Source and External Links

What Is Machine Vision? - Machine vision combines smart cameras, industrial PCs, and AI models to enable automated tasks such as quality inspection, part identification, and robotic guidance in industrial settings, allowing for real-time decision-making in manufacturing environments.

What is Machine Vision? - Machine vision uses video cameras and digital signal processing to capture and analyze images, often integrated with AI to recognize objects, inspect materials, and make quality control decisions in automated systems.

Machine vision basics: definitions, uses, and benefits - Machine vision enables automated systems to inspect, measure, and sort manufactured parts and products at high speed and accuracy, generating critical data for efficiency and quality improvements in industries like logistics and manufacturing.

dowidth.com

dowidth.com