Smart factories leverage advanced automation, IoT sensors, and AI-driven analytics to enhance production efficiency, predictive maintenance, and real-time decision-making. Green manufacturing focuses on sustainable practices, minimizing waste, reducing carbon emissions, and utilizing eco-friendly materials to promote environmental responsibility. Explore how integrating smart factory technologies with green manufacturing principles transforms modern industrial operations.

Why it is important

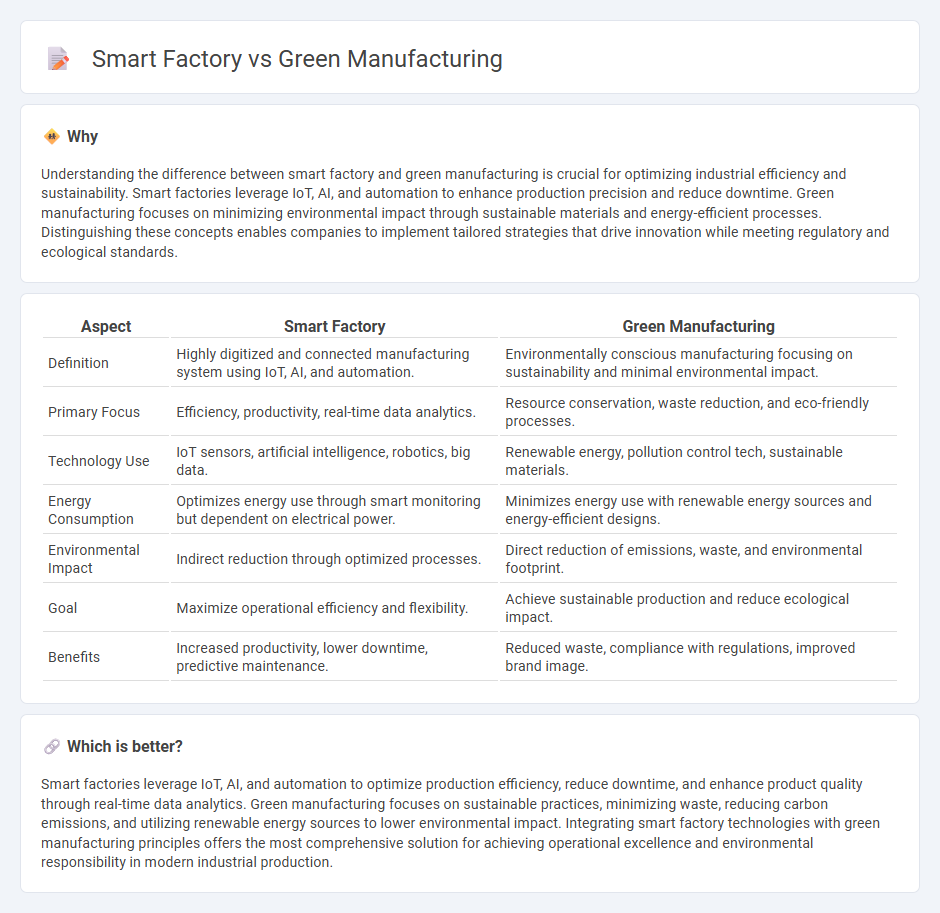

Understanding the difference between smart factory and green manufacturing is crucial for optimizing industrial efficiency and sustainability. Smart factories leverage IoT, AI, and automation to enhance production precision and reduce downtime. Green manufacturing focuses on minimizing environmental impact through sustainable materials and energy-efficient processes. Distinguishing these concepts enables companies to implement tailored strategies that drive innovation while meeting regulatory and ecological standards.

Comparison Table

| Aspect | Smart Factory | Green Manufacturing |

|---|---|---|

| Definition | Highly digitized and connected manufacturing system using IoT, AI, and automation. | Environmentally conscious manufacturing focusing on sustainability and minimal environmental impact. |

| Primary Focus | Efficiency, productivity, real-time data analytics. | Resource conservation, waste reduction, and eco-friendly processes. |

| Technology Use | IoT sensors, artificial intelligence, robotics, big data. | Renewable energy, pollution control tech, sustainable materials. |

| Energy Consumption | Optimizes energy use through smart monitoring but dependent on electrical power. | Minimizes energy use with renewable energy sources and energy-efficient designs. |

| Environmental Impact | Indirect reduction through optimized processes. | Direct reduction of emissions, waste, and environmental footprint. |

| Goal | Maximize operational efficiency and flexibility. | Achieve sustainable production and reduce ecological impact. |

| Benefits | Increased productivity, lower downtime, predictive maintenance. | Reduced waste, compliance with regulations, improved brand image. |

Which is better?

Smart factories leverage IoT, AI, and automation to optimize production efficiency, reduce downtime, and enhance product quality through real-time data analytics. Green manufacturing focuses on sustainable practices, minimizing waste, reducing carbon emissions, and utilizing renewable energy sources to lower environmental impact. Integrating smart factory technologies with green manufacturing principles offers the most comprehensive solution for achieving operational excellence and environmental responsibility in modern industrial production.

Connection

Smart factories integrate advanced technologies like IoT, AI, and automation to optimize resource use and reduce waste, directly supporting green manufacturing goals. By enabling real-time monitoring and predictive maintenance, smart factories minimize energy consumption and emissions, enhancing environmental sustainability. This synergy accelerates the transition to eco-friendly production processes, lowering the carbon footprint of manufacturing operations.

Key Terms

**Green Manufacturing:**

Green manufacturing emphasizes sustainable production processes that minimize environmental impact through energy efficiency, waste reduction, and the use of renewable resources. It integrates eco-friendly materials and technologies to lower carbon footprints and promote resource conservation throughout the product lifecycle. Explore more about how green manufacturing drives sustainable innovation and corporate responsibility.

Energy Efficiency

Green manufacturing emphasizes reducing environmental impact through sustainable practices and energy-efficient technologies, targeting lower carbon footprints and minimized waste. Smart factories leverage advanced automation, IoT, and data analytics to optimize energy consumption, enhance production efficiency, and reduce operational costs. Explore key strategies that combine these approaches to maximize energy efficiency in modern industrial settings.

Sustainable Materials

Green manufacturing emphasizes the use of sustainable materials such as recycled metals, bioplastics, and non-toxic chemicals to minimize environmental impact and reduce waste. Smart factories integrate advanced technologies like IoT sensors and AI to optimize material usage, monitor resource efficiency, and ensure traceability of sustainable inputs throughout the production process. Explore how combining sustainable materials with smart factory innovations drives eco-friendly manufacturing forward.

Source and External Links

What Is Green Manufacturing? - IBM - Green manufacturing is the process of creating products in a way that reduces carbon footprint by minimizing negative environmental impacts, conserving energy and natural resources, and often using renewable energy and efficient technologies to improve sustainability and business benefits.

What is Green Manufacturing? (Plus 5 Steps to a Greener Future) - Green manufacturing, also known as sustainable manufacturing, emphasizes minimizing environmental impacts and maximizing resource efficiency through lean principles, eco-friendly materials, and energy reduction to build more sustainable production processes.

Green Manufacturing: The Business Benefits of Sustainability - Green manufacturing involves using fewer environmental pollutants and natural resources to reduce waste and emissions, which benefits both the planet and businesses by cutting costs, improving productivity, and supporting sustainability goals.

dowidth.com

dowidth.com