Collaborative robots (cobots) enhance manufacturing flexibility by working safely alongside human operators, performing tasks such as assembly and quality inspection with precision. Machine tending systems specialize in automating the loading and unloading of CNC machines, increasing production efficiency and consistency in high-volume environments. Explore the distinct advantages of each technology to optimize your manufacturing operations.

Why it is important

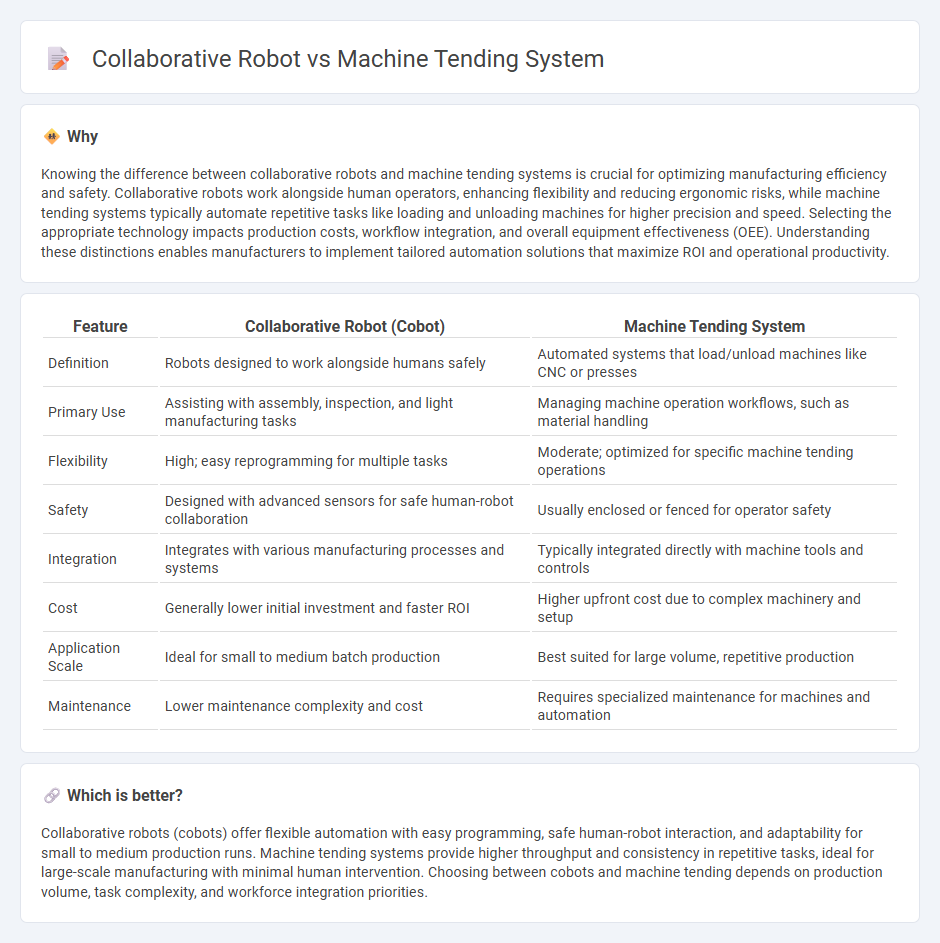

Knowing the difference between collaborative robots and machine tending systems is crucial for optimizing manufacturing efficiency and safety. Collaborative robots work alongside human operators, enhancing flexibility and reducing ergonomic risks, while machine tending systems typically automate repetitive tasks like loading and unloading machines for higher precision and speed. Selecting the appropriate technology impacts production costs, workflow integration, and overall equipment effectiveness (OEE). Understanding these distinctions enables manufacturers to implement tailored automation solutions that maximize ROI and operational productivity.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Machine Tending System |

|---|---|---|

| Definition | Robots designed to work alongside humans safely | Automated systems that load/unload machines like CNC or presses |

| Primary Use | Assisting with assembly, inspection, and light manufacturing tasks | Managing machine operation workflows, such as material handling |

| Flexibility | High; easy reprogramming for multiple tasks | Moderate; optimized for specific machine tending operations |

| Safety | Designed with advanced sensors for safe human-robot collaboration | Usually enclosed or fenced for operator safety |

| Integration | Integrates with various manufacturing processes and systems | Typically integrated directly with machine tools and controls |

| Cost | Generally lower initial investment and faster ROI | Higher upfront cost due to complex machinery and setup |

| Application Scale | Ideal for small to medium batch production | Best suited for large volume, repetitive production |

| Maintenance | Lower maintenance complexity and cost | Requires specialized maintenance for machines and automation |

Which is better?

Collaborative robots (cobots) offer flexible automation with easy programming, safe human-robot interaction, and adaptability for small to medium production runs. Machine tending systems provide higher throughput and consistency in repetitive tasks, ideal for large-scale manufacturing with minimal human intervention. Choosing between cobots and machine tending depends on production volume, task complexity, and workforce integration priorities.

Connection

Collaborative robots (cobots) integrate seamlessly with machine tending systems by automating repetitive tasks such as loading, unloading, and inspection, enhancing production efficiency and precision. These robots work alongside human operators, improving safety and flexibility within manufacturing environments. The synergy between cobots and machine tending systems reduces downtime and optimizes workflow, driving cost savings and higher throughput.

Key Terms

**Machine tending system:**

Machine tending systems are automated solutions designed to load and unload machines such as CNC machines, injection molding machines, or press brakes, significantly increasing production efficiency and reducing labor costs. These systems integrate advanced robotics, sensors, and software to ensure precise handling, consistent cycle times, and improved safety in manufacturing environments. Discover how machine tending systems can transform your production line by exploring their capabilities and benefits in detail.

Automated loading/unloading

Automated loading and unloading are critical applications in machine tending systems, where high precision and speed enhance manufacturing efficiency. Collaborative robots offer flexible, adaptive automation by working safely alongside human operators, optimizing tasks like part transfer and reducing downtime. Explore the advantages of each technology to determine the best fit for your specific production needs.

CNC integration

Machine tending systems are designed for automated loading and unloading of CNC machines, optimizing cycle times and improving precision in manufacturing environments. Collaborative robots (cobots) offer flexible integration with CNC machines, enabling safe human-robot interaction and adapting to various tasks without extensive programming. Explore further how CNC integration differs between machine tending systems and cobots for enhanced production efficiency.

Source and External Links

Machine tending - Wikipedia - Machine tending is the automated operation of industrial machine tools, primarily using robot systems to load and unload parts, with additional functions like inspection, deburring, and packaging to increase productivity, quality, and safety.

Robotic Machine Tending - Applied Manufacturing Technologies - Robotic machine tending automates the transfer of materials and parts to and from machines, drastically improving uptime, accuracy, and throughput compared to manual processes, and is commonly used in high-volume manufacturing applications like automotive component processing.

Robotic Machine Tending - Vention - Vention offers modular, robot-agnostic machine tending solutions that automate CNC loading and unloading, are easy to assemble and deploy, and can provide up to a full day of machine autonomy with quick ROI and flexible configurations for different production needs.

dowidth.com

dowidth.com