Smart dust technology involves deploying tiny, wireless sensors to monitor manufacturing processes at a granular level, enhancing real-time data collection and operational efficiency. Predictive maintenance uses data analytics and machine learning algorithms to predict equipment failures before they occur, minimizing downtime and reducing maintenance costs. Discover how integrating smart dust with predictive maintenance can revolutionize manufacturing reliability and productivity.

Why it is important

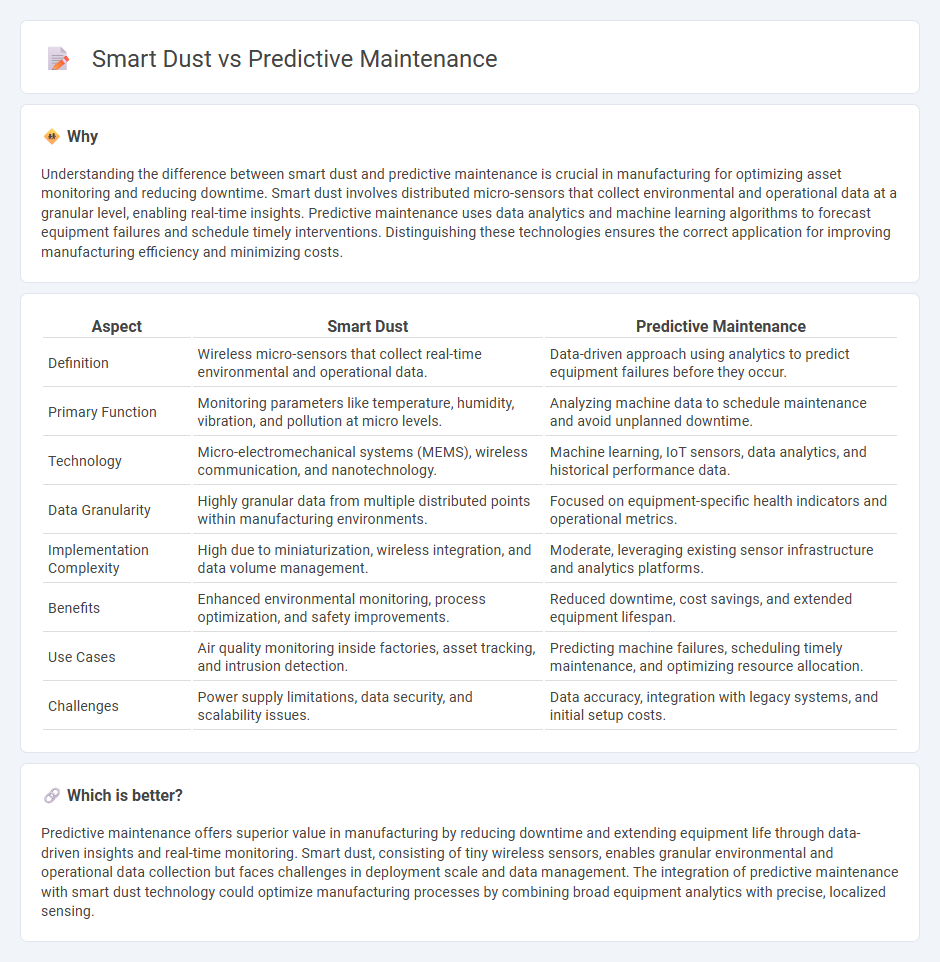

Understanding the difference between smart dust and predictive maintenance is crucial in manufacturing for optimizing asset monitoring and reducing downtime. Smart dust involves distributed micro-sensors that collect environmental and operational data at a granular level, enabling real-time insights. Predictive maintenance uses data analytics and machine learning algorithms to forecast equipment failures and schedule timely interventions. Distinguishing these technologies ensures the correct application for improving manufacturing efficiency and minimizing costs.

Comparison Table

| Aspect | Smart Dust | Predictive Maintenance |

|---|---|---|

| Definition | Wireless micro-sensors that collect real-time environmental and operational data. | Data-driven approach using analytics to predict equipment failures before they occur. |

| Primary Function | Monitoring parameters like temperature, humidity, vibration, and pollution at micro levels. | Analyzing machine data to schedule maintenance and avoid unplanned downtime. |

| Technology | Micro-electromechanical systems (MEMS), wireless communication, and nanotechnology. | Machine learning, IoT sensors, data analytics, and historical performance data. |

| Data Granularity | Highly granular data from multiple distributed points within manufacturing environments. | Focused on equipment-specific health indicators and operational metrics. |

| Implementation Complexity | High due to miniaturization, wireless integration, and data volume management. | Moderate, leveraging existing sensor infrastructure and analytics platforms. |

| Benefits | Enhanced environmental monitoring, process optimization, and safety improvements. | Reduced downtime, cost savings, and extended equipment lifespan. |

| Use Cases | Air quality monitoring inside factories, asset tracking, and intrusion detection. | Predicting machine failures, scheduling timely maintenance, and optimizing resource allocation. |

| Challenges | Power supply limitations, data security, and scalability issues. | Data accuracy, integration with legacy systems, and initial setup costs. |

Which is better?

Predictive maintenance offers superior value in manufacturing by reducing downtime and extending equipment life through data-driven insights and real-time monitoring. Smart dust, consisting of tiny wireless sensors, enables granular environmental and operational data collection but faces challenges in deployment scale and data management. The integration of predictive maintenance with smart dust technology could optimize manufacturing processes by combining broad equipment analytics with precise, localized sensing.

Connection

Smart dust sensors enable real-time monitoring of manufacturing equipment by collecting granular data on machine conditions, which predictive maintenance systems analyze to forecast potential failures. This integration reduces unexpected downtime and optimizes maintenance schedules, enhancing overall operational efficiency. Implementing smart dust-driven predictive maintenance leads to cost savings and improved asset longevity in manufacturing environments.

Key Terms

Predictive maintenance:

Predictive maintenance leverages IoT sensors and machine learning algorithms to analyze equipment data, enabling early detection of potential failures and reducing downtime by up to 30%. This proactive approach helps industries save millions annually by optimizing maintenance schedules and extending asset lifespan. Explore how predictive maintenance transforms operational efficiency and cost management in various sectors.

Condition monitoring

Predictive maintenance leverages real-time data analytics and sensor technology to monitor equipment conditions, identifying potential failures before they occur, thereby reducing downtime and maintenance costs. Smart dust consists of tiny wireless microelectromechanical sensors (MEMS) that can be dispersed over an area to provide granular environmental and operational data for precise condition monitoring. Discover how integrating predictive maintenance with smart dust technology enhances asset reliability and operational efficiency.

Failure prediction

Predictive maintenance leverages advanced data analytics and machine learning algorithms to analyze sensor data, enabling accurate failure prediction and reducing equipment downtime. Smart dust consists of tiny, wireless sensors capable of real-time environmental monitoring, offering granular insights that enhance failure detection in critical systems. Explore how these technologies revolutionize failure prediction techniques for improved operational efficiency.

Source and External Links

What is Predictive Maintenance? - Predictive maintenance uses sensor data and machine learning to continuously assess equipment health and predict future failures, enabling maintenance only when necessary to avoid downtime and reduce costs.

Predictive maintenance - Predictive maintenance estimates when equipment requires service based on its actual condition using measurements and analytics, improving scheduling, reducing unplanned downtime, and extending asset life.

What is Predictive Maintenance? Benefits, Challenges & ... - Predictive maintenance in fleet management analyzes real-time vehicle data to predict failures weeks ahead, optimizing uptime, reducing costs, and enhancing safety by alerting managers before breakdowns occur.

dowidth.com

dowidth.com