Machine vision leverages cameras and image processing algorithms to inspect and analyze products on manufacturing lines, enhancing quality control and automation. In contrast, 3D scanning captures precise spatial geometry and surface details of objects, enabling detailed measurements and complex design validation. Explore how integrating machine vision and 3D scanning technologies can revolutionize manufacturing accuracy and efficiency.

Why it is important

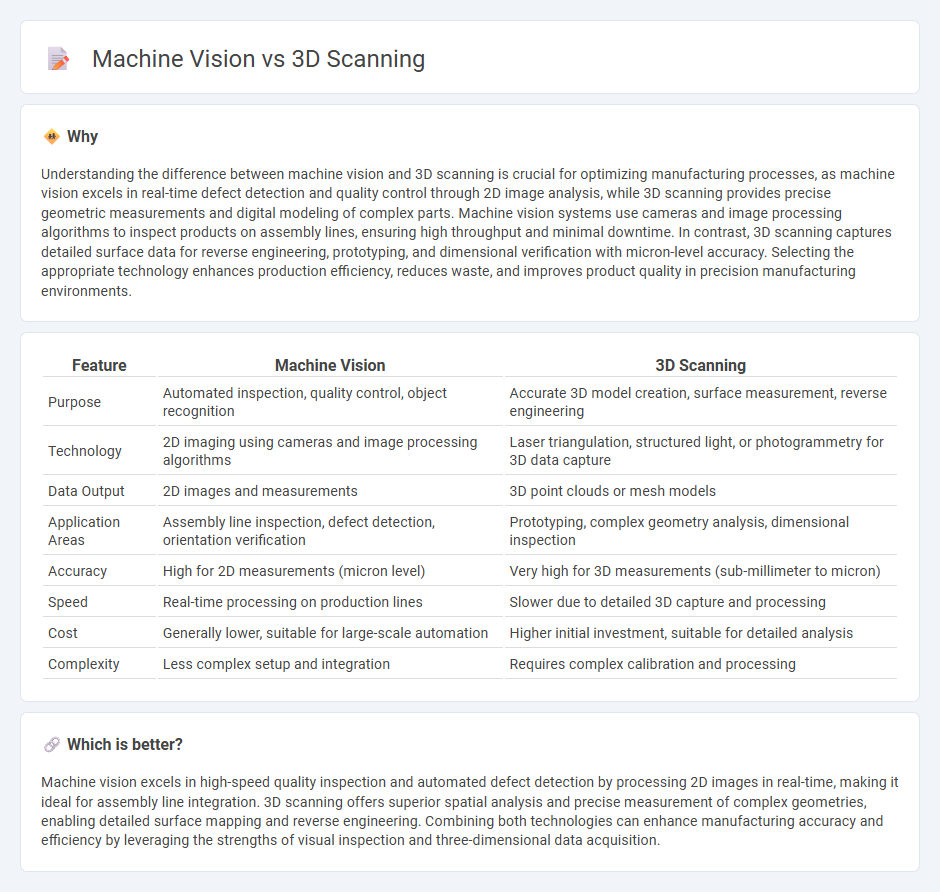

Understanding the difference between machine vision and 3D scanning is crucial for optimizing manufacturing processes, as machine vision excels in real-time defect detection and quality control through 2D image analysis, while 3D scanning provides precise geometric measurements and digital modeling of complex parts. Machine vision systems use cameras and image processing algorithms to inspect products on assembly lines, ensuring high throughput and minimal downtime. In contrast, 3D scanning captures detailed surface data for reverse engineering, prototyping, and dimensional verification with micron-level accuracy. Selecting the appropriate technology enhances production efficiency, reduces waste, and improves product quality in precision manufacturing environments.

Comparison Table

| Feature | Machine Vision | 3D Scanning |

|---|---|---|

| Purpose | Automated inspection, quality control, object recognition | Accurate 3D model creation, surface measurement, reverse engineering |

| Technology | 2D imaging using cameras and image processing algorithms | Laser triangulation, structured light, or photogrammetry for 3D data capture |

| Data Output | 2D images and measurements | 3D point clouds or mesh models |

| Application Areas | Assembly line inspection, defect detection, orientation verification | Prototyping, complex geometry analysis, dimensional inspection |

| Accuracy | High for 2D measurements (micron level) | Very high for 3D measurements (sub-millimeter to micron) |

| Speed | Real-time processing on production lines | Slower due to detailed 3D capture and processing |

| Cost | Generally lower, suitable for large-scale automation | Higher initial investment, suitable for detailed analysis |

| Complexity | Less complex setup and integration | Requires complex calibration and processing |

Which is better?

Machine vision excels in high-speed quality inspection and automated defect detection by processing 2D images in real-time, making it ideal for assembly line integration. 3D scanning offers superior spatial analysis and precise measurement of complex geometries, enabling detailed surface mapping and reverse engineering. Combining both technologies can enhance manufacturing accuracy and efficiency by leveraging the strengths of visual inspection and three-dimensional data acquisition.

Connection

Machine vision and 3D scanning are integral technologies in modern manufacturing, collaborating to enhance precision and quality control. Machine vision systems capture detailed 2D images for surface inspection, while 3D scanning collects spatial data to create accurate models of objects, enabling thorough dimensional analysis. Their integration streamlines automated inspection processes, reducing defects and optimizing production efficiency.

Key Terms

**3D Scanning:**

3D scanning captures precise spatial data by using laser, structured light, or photogrammetry to create detailed digital models of objects or environments, enabling accurate measurements and quality control in manufacturing, healthcare, and cultural heritage preservation. This technology excels in scenarios requiring high-resolution, volumetric analysis and complex surface geometry reconstruction. Explore how 3D scanning can revolutionize your workflow and enhance accuracy in your industry.

Point Cloud

Point cloud data serves as a fundamental element in 3D scanning, enabling detailed spatial representation of objects and environments through millions of precise 3D coordinates. Machine vision systems leverage point cloud data primarily for object detection, measurement, and quality control in automated industrial processes, offering real-time analysis but often with lower spatial resolution than dedicated 3D scanners. Explore in-depth comparisons of point cloud accuracy, processing techniques, and application specificities to understand their distinct roles and advantages.

Structured Light

Structured Light technology in 3D scanning uses projected light patterns to capture precise surface geometry, enabling high-resolution, accurate depth measurements. Machine vision systems employing Structured Light excel in industrial automation, quality control, and robotics by providing detailed 3D data for object detection and inspection. Explore how Structured Light enhances 3D scanning and machine vision applications to optimize industrial processes and innovation.

Source and External Links

3D scanning - Wikipedia - 3D scanning is the process of analyzing a real-world object or environment to collect three-dimensional data about its shape and appearance, enabling the construction of digital 3D models from that data.

What is 3D scanning? A beginner's guide - 3D scanning captures a physical subject to accurately represent its geometry in a digital environment using contact or, more commonly, non-contact methods such as laser triangulation or time-of-flight techniques.

What is 3D Scanning? Basics and Applications - Sculpteo - 3D scanning digitally captures an object's shape and appearance, often using laser light to create highly accurate point clouds, which can be processed into CAD models.

dowidth.com

dowidth.com