Adaptive machining uses real-time sensor data and machine learning algorithms to adjust cutting parameters dynamically, improving precision and reducing tool wear. Process optimization focuses on streamlining workflows, minimizing waste, and enhancing productivity through statistical analysis and process control techniques. Discover how integrating adaptive machining and process optimization can revolutionize manufacturing efficiency.

Why it is important

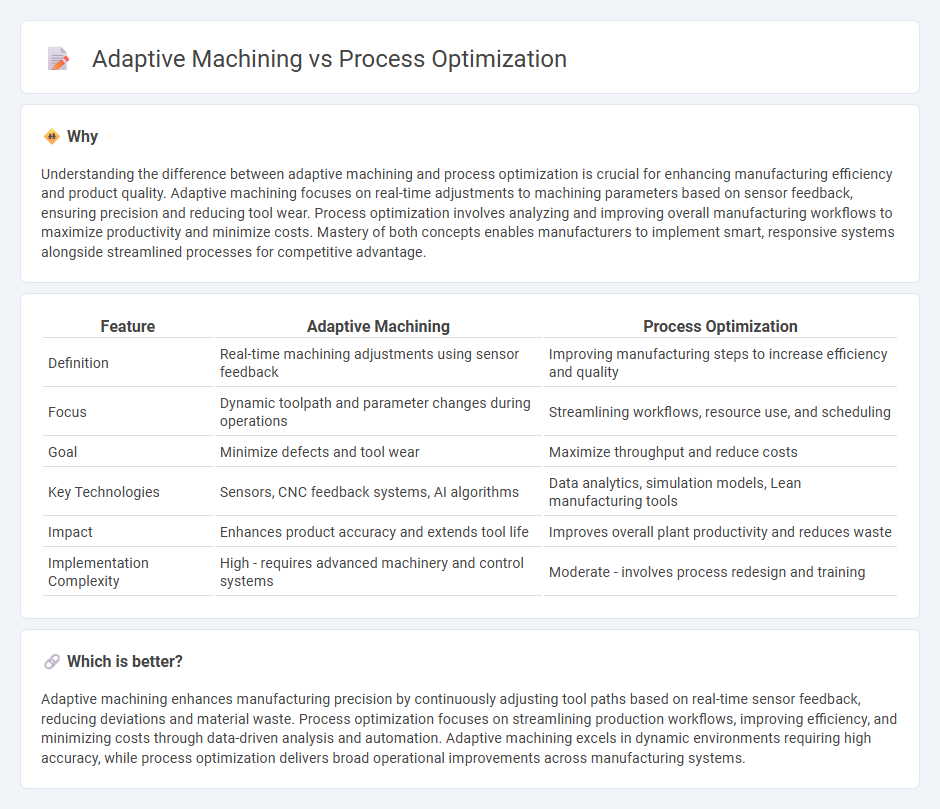

Understanding the difference between adaptive machining and process optimization is crucial for enhancing manufacturing efficiency and product quality. Adaptive machining focuses on real-time adjustments to machining parameters based on sensor feedback, ensuring precision and reducing tool wear. Process optimization involves analyzing and improving overall manufacturing workflows to maximize productivity and minimize costs. Mastery of both concepts enables manufacturers to implement smart, responsive systems alongside streamlined processes for competitive advantage.

Comparison Table

| Feature | Adaptive Machining | Process Optimization |

|---|---|---|

| Definition | Real-time machining adjustments using sensor feedback | Improving manufacturing steps to increase efficiency and quality |

| Focus | Dynamic toolpath and parameter changes during operations | Streamlining workflows, resource use, and scheduling |

| Goal | Minimize defects and tool wear | Maximize throughput and reduce costs |

| Key Technologies | Sensors, CNC feedback systems, AI algorithms | Data analytics, simulation models, Lean manufacturing tools |

| Impact | Enhances product accuracy and extends tool life | Improves overall plant productivity and reduces waste |

| Implementation Complexity | High - requires advanced machinery and control systems | Moderate - involves process redesign and training |

Which is better?

Adaptive machining enhances manufacturing precision by continuously adjusting tool paths based on real-time sensor feedback, reducing deviations and material waste. Process optimization focuses on streamlining production workflows, improving efficiency, and minimizing costs through data-driven analysis and automation. Adaptive machining excels in dynamic environments requiring high accuracy, while process optimization delivers broad operational improvements across manufacturing systems.

Connection

Adaptive machining enhances process optimization by employing real-time data and sensors to adjust cutting parameters dynamically, ensuring precision and reducing waste. Process optimization benefits from adaptive machining through improved cycle times, minimized tool wear, and consistent product quality. Integration of adaptive machining techniques leads to more efficient resource utilization and higher manufacturing throughput.

Key Terms

**Process optimization:**

Process optimization enhances manufacturing efficiency by systematically analyzing and refining production workflows, tool paths, and operational parameters to reduce cycle times and minimize waste. It employs data-driven techniques such as statistical process control, machine learning algorithms, and real-time monitoring to improve product quality and consistency. Discover how advanced process optimization methods can transform your machining operations for superior performance.

Lean manufacturing

Process optimization in Lean manufacturing emphasizes streamlining workflows, reducing waste, and enhancing efficiency through standardized procedures and continuous improvement practices. Adaptive machining integrates real-time data and intelligent control systems to dynamically adjust machining parameters, minimizing defects and maximizing resource utilization. Explore how combining these approaches can elevate Lean manufacturing performance and operational excellence.

Six Sigma

Process optimization in manufacturing leverages Six Sigma methodologies to reduce variability, improve quality, and streamline production workflows, leading to significant cost savings and enhanced product reliability. Adaptive machining integrates real-time data adjustments and machine learning algorithms to dynamically modify processes, aiming to maintain optimal performance despite variations in raw materials or equipment conditions. Explore how combining Six Sigma principles with adaptive machining strategies can revolutionize manufacturing efficiency and quality control.

Source and External Links

Process optimization - Wikipedia - Process optimization involves adjusting processes to maximize effectiveness (such as minimizing cost or maximizing throughput) without violating constraints, focusing on equipment, operating procedures, and control optimization in industrial settings.

Process Optimization: Increasing Business Efficiency - SixSigma.us - Process optimization is a structured approach to systematically improve business operations by identifying high-impact processes, analyzing current performance with data and process mapping, and setting measurable goals for efficiency and quality improvements.

Process Optimization Explained - Methods, Benefits & Tools - Process optimization uses techniques such as process mapping, process mining, root-cause analysis, and frameworks like DMAIC and Six Sigma to analyze and improve business processes for maximum efficiency and quality.

dowidth.com

dowidth.com