Closed-loop manufacturing integrates real-time feedback systems to continuously monitor and adjust production processes, enhancing precision and reducing waste. Subtractive manufacturing involves removing material from a solid block to create a final product, commonly through machining, milling, or cutting techniques. Discover how these manufacturing methods impact efficiency, cost, and sustainability in modern production.

Why it is important

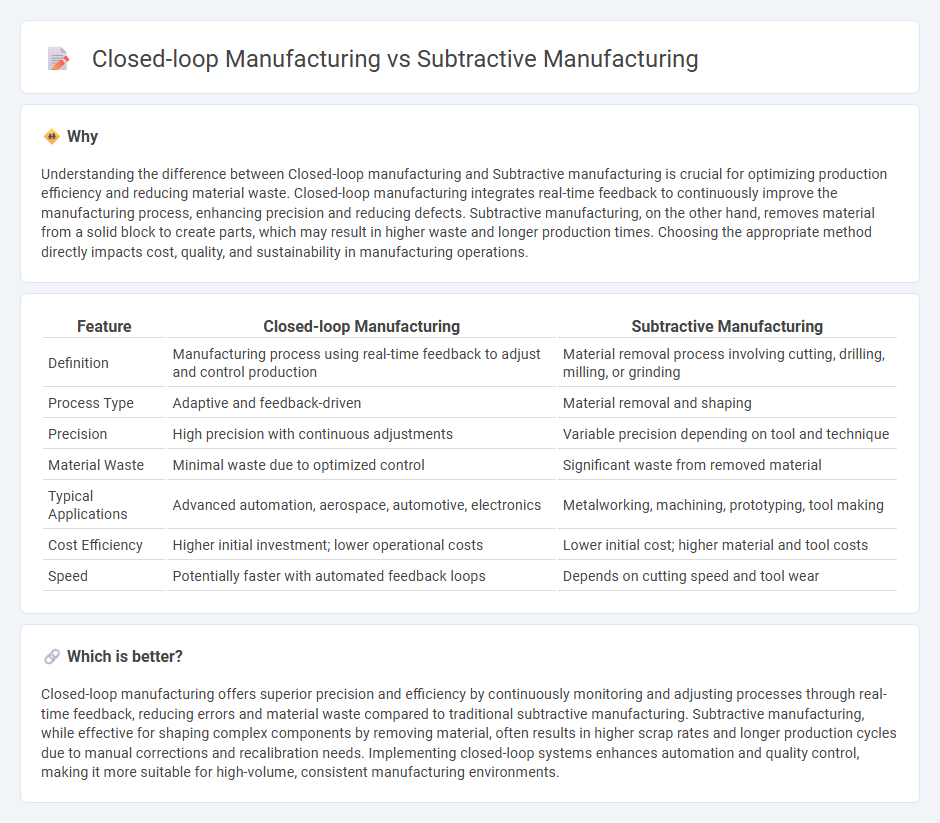

Understanding the difference between Closed-loop manufacturing and Subtractive manufacturing is crucial for optimizing production efficiency and reducing material waste. Closed-loop manufacturing integrates real-time feedback to continuously improve the manufacturing process, enhancing precision and reducing defects. Subtractive manufacturing, on the other hand, removes material from a solid block to create parts, which may result in higher waste and longer production times. Choosing the appropriate method directly impacts cost, quality, and sustainability in manufacturing operations.

Comparison Table

| Feature | Closed-loop Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Definition | Manufacturing process using real-time feedback to adjust and control production | Material removal process involving cutting, drilling, milling, or grinding |

| Process Type | Adaptive and feedback-driven | Material removal and shaping |

| Precision | High precision with continuous adjustments | Variable precision depending on tool and technique |

| Material Waste | Minimal waste due to optimized control | Significant waste from removed material |

| Typical Applications | Advanced automation, aerospace, automotive, electronics | Metalworking, machining, prototyping, tool making |

| Cost Efficiency | Higher initial investment; lower operational costs | Lower initial cost; higher material and tool costs |

| Speed | Potentially faster with automated feedback loops | Depends on cutting speed and tool wear |

Which is better?

Closed-loop manufacturing offers superior precision and efficiency by continuously monitoring and adjusting processes through real-time feedback, reducing errors and material waste compared to traditional subtractive manufacturing. Subtractive manufacturing, while effective for shaping complex components by removing material, often results in higher scrap rates and longer production cycles due to manual corrections and recalibration needs. Implementing closed-loop systems enhances automation and quality control, making it more suitable for high-volume, consistent manufacturing environments.

Connection

Closed-loop manufacturing integrates real-time feedback systems to continuously monitor and adjust subtractive manufacturing processes like milling and turning, enhancing precision and reducing material waste. By utilizing sensors and control algorithms, closed-loop systems ensure that subtractive manufacturing achieves tighter tolerances and consistent quality during metal removal operations. This synergy enables manufacturers to optimize machining parameters dynamically, improving production efficiency and product reliability.

Key Terms

Material removal

Subtractive manufacturing involves the process of removing material from a solid block through machining operations like milling or turning to achieve the desired shape, emphasizing precision in material removal. Closed-loop manufacturing integrates real-time feedback and sensor data to continuously monitor and adjust the machining process, enhancing accuracy and reducing material waste. Explore the advantages and applications of both methods to optimize your manufacturing workflow.

Feedback control

Subtractive manufacturing removes material from a workpiece through processes like milling or turning, relying primarily on preset tool paths without continuous adjustment during production. Closed-loop manufacturing integrates real-time feedback control systems, using sensors and monitoring data to dynamically adjust machining parameters, enhancing precision and reducing errors. Explore how feedback control in closed-loop systems revolutionizes manufacturing accuracy and efficiency.

Precision sensors

Precision sensors play a crucial role in both subtractive manufacturing and closed-loop manufacturing by ensuring accurate dimensional control and real-time feedback during machining processes. In subtractive manufacturing, sensors monitor tool position and wear to maintain tight tolerances, while closed-loop systems utilize sensor data to dynamically adjust machine parameters for enhanced precision and reduced defects. Explore the latest advancements in precision sensors shaping the future of manufacturing accuracy.

Source and External Links

Additive vs. Subtractive Manufacturing - Formlabs - Subtractive manufacturing involves material removal processes like cutting, drilling, and grinding from solid blocks using mostly CNC machines to create parts from plastics or metals with tight tolerances and complex geometries.

Subtractive Manufacturing vs. Additive Manufacturing | Xometry Pro - Subtractive manufacturing creates objects by progressively removing material from a solid block or sheet, typically via CNC machining, achieving high dimensional accuracy and working with a wide range of materials including plastics, metals, wood, and stone.

Subtractive Manufacturing: Past, Present, and Future - Subtractive manufacturing is the process of cutting, shaping, or finishing material to create desired forms and is evolving with advances that allow hybrid manufacturing, combining additive and subtractive techniques for enhanced complexity and finish quality.

dowidth.com

dowidth.com