Biofabrication involves the layer-by-layer assembly of living cells and biomaterials to create complex tissues and organs, leveraging bioprinting technologies to emulate natural biological structures. In contrast, 3D printing primarily uses non-living materials like plastics, metals, and ceramics to fabricate precise, functional prototypes and components across various industries. Explore the distinctions and applications of these innovative manufacturing techniques to understand their transformative impact.

Why it is important

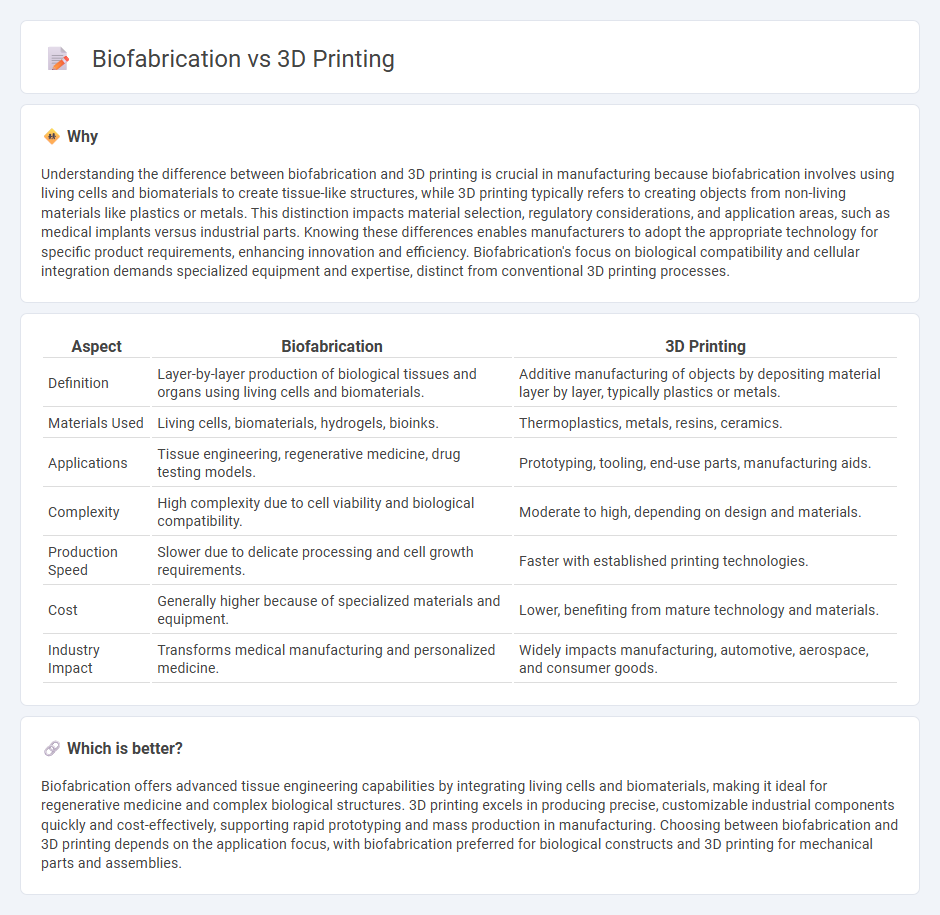

Understanding the difference between biofabrication and 3D printing is crucial in manufacturing because biofabrication involves using living cells and biomaterials to create tissue-like structures, while 3D printing typically refers to creating objects from non-living materials like plastics or metals. This distinction impacts material selection, regulatory considerations, and application areas, such as medical implants versus industrial parts. Knowing these differences enables manufacturers to adopt the appropriate technology for specific product requirements, enhancing innovation and efficiency. Biofabrication's focus on biological compatibility and cellular integration demands specialized equipment and expertise, distinct from conventional 3D printing processes.

Comparison Table

| Aspect | Biofabrication | 3D Printing |

|---|---|---|

| Definition | Layer-by-layer production of biological tissues and organs using living cells and biomaterials. | Additive manufacturing of objects by depositing material layer by layer, typically plastics or metals. |

| Materials Used | Living cells, biomaterials, hydrogels, bioinks. | Thermoplastics, metals, resins, ceramics. |

| Applications | Tissue engineering, regenerative medicine, drug testing models. | Prototyping, tooling, end-use parts, manufacturing aids. |

| Complexity | High complexity due to cell viability and biological compatibility. | Moderate to high, depending on design and materials. |

| Production Speed | Slower due to delicate processing and cell growth requirements. | Faster with established printing technologies. |

| Cost | Generally higher because of specialized materials and equipment. | Lower, benefiting from mature technology and materials. |

| Industry Impact | Transforms medical manufacturing and personalized medicine. | Widely impacts manufacturing, automotive, aerospace, and consumer goods. |

Which is better?

Biofabrication offers advanced tissue engineering capabilities by integrating living cells and biomaterials, making it ideal for regenerative medicine and complex biological structures. 3D printing excels in producing precise, customizable industrial components quickly and cost-effectively, supporting rapid prototyping and mass production in manufacturing. Choosing between biofabrication and 3D printing depends on the application focus, with biofabrication preferred for biological constructs and 3D printing for mechanical parts and assemblies.

Connection

Biofabrication leverages 3D printing technology to create complex biological structures by precisely depositing cells, biomaterials, and growth factors layer by layer. This integration enables customized tissue engineering and organ development with high spatial accuracy and scalability. Advancements in 3D bioprinting materials and techniques significantly enhance the manufacturing of implants, scaffolds, and regenerative medicine applications.

Key Terms

**3D Printing:**

3D printing revolutionizes manufacturing by enabling precise layer-by-layer construction of complex objects using materials like plastics, metals, and resins, achieving high customization and rapid prototyping. Advanced techniques such as stereolithography (SLA) and fused deposition modeling (FDM) enhance resolution and material versatility, making 3D printing a cornerstone in industries ranging from aerospace to medical device fabrication. Explore detailed insights into 3D printing processes, applications, and innovations to fully understand its transformative impact.

Additive manufacturing

Additive manufacturing in 3D printing builds intricate structures layer by layer using materials like plastics and metals, enabling rapid prototyping and customized production. Biofabrication extends this process by integrating living cells and biomaterials to create tissue-like constructs for medical applications such as regenerative medicine and drug testing. Explore further to understand the technological advancements and biomedical potentials of these additive manufacturing techniques.

Layer-by-layer deposition

Layer-by-layer deposition in 3D printing involves the precise placement of materials such as thermoplastics and resins to build structures, typically used in manufacturing and prototyping. In biofabrication, this technique is adapted to deposit living cells and biomaterials, enabling the creation of complex tissue constructs for regenerative medicine. Explore the advancements and applications that distinguish these technologies in modern production and healthcare.

Source and External Links

What is 3D Printing? | 3D Printing Software - Autodesk - 3D printing is an additive manufacturing process where material is added layer by layer using a print head to create objects from digital models, useful for prototyping and production with materials like plastics and metals, though scalability and cost remain challenges for large runs.

3D printing - Wikipedia - 3D printing, or additive manufacturing, constructs 3D objects from CAD models by depositing material layer by layer and enables creating complex geometries otherwise difficult to make, evolving from rapid prototyping to industrial production technology.

3D printing: What is it & how does it work? | Protolabs Network - 3D printing enables fast prototyping and customized production parts, valuable in industries like aerospace, automotive, and healthcare for making complex, lightweight, or consolidated parts using various printing technologies such as FDM, SLA, and SLS.

dowidth.com

dowidth.com