Factory as a Service (FaaS) offers on-demand manufacturing capabilities by leveraging cloud-based platforms and flexible production lines, allowing businesses to scale operations without heavy upfront investments. Lights-out manufacturing employs fully automated, unmanned factories that operate 24/7 using robotics, IoT sensors, and AI-driven controls to maximize efficiency and minimize human intervention. Explore how these innovative manufacturing models can transform your production strategy.

Why it is important

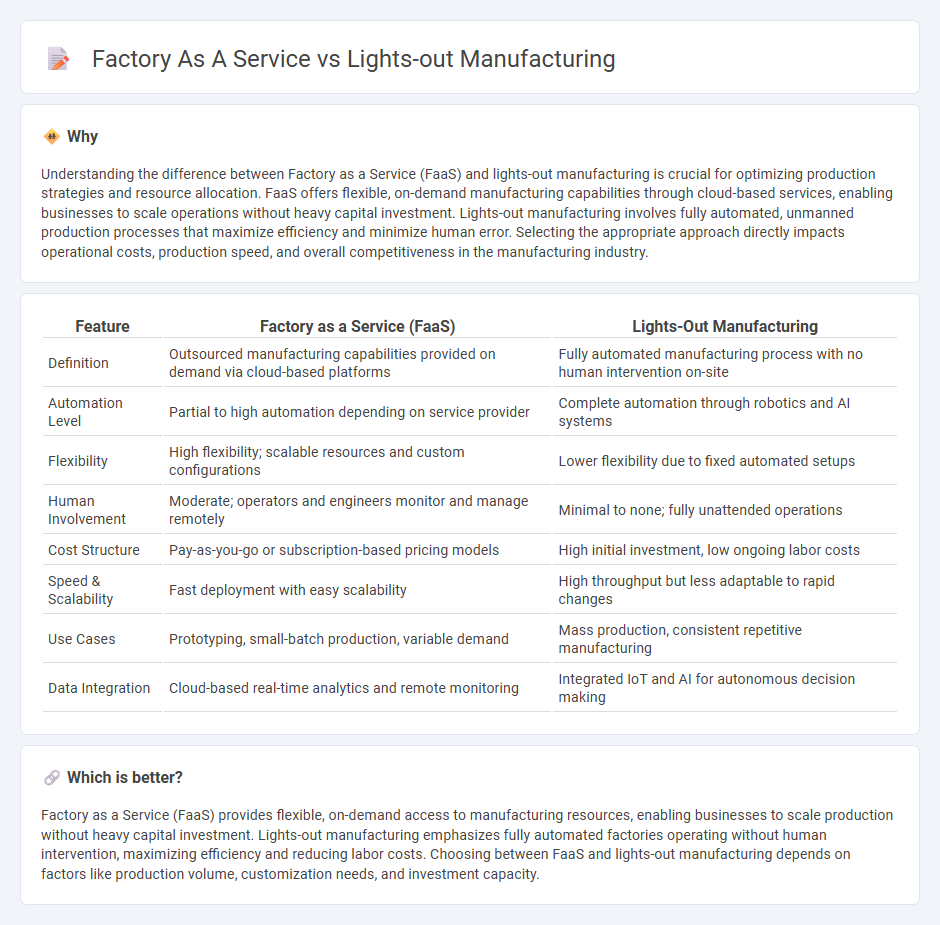

Understanding the difference between Factory as a Service (FaaS) and lights-out manufacturing is crucial for optimizing production strategies and resource allocation. FaaS offers flexible, on-demand manufacturing capabilities through cloud-based services, enabling businesses to scale operations without heavy capital investment. Lights-out manufacturing involves fully automated, unmanned production processes that maximize efficiency and minimize human error. Selecting the appropriate approach directly impacts operational costs, production speed, and overall competitiveness in the manufacturing industry.

Comparison Table

| Feature | Factory as a Service (FaaS) | Lights-Out Manufacturing |

|---|---|---|

| Definition | Outsourced manufacturing capabilities provided on demand via cloud-based platforms | Fully automated manufacturing process with no human intervention on-site |

| Automation Level | Partial to high automation depending on service provider | Complete automation through robotics and AI systems |

| Flexibility | High flexibility; scalable resources and custom configurations | Lower flexibility due to fixed automated setups |

| Human Involvement | Moderate; operators and engineers monitor and manage remotely | Minimal to none; fully unattended operations |

| Cost Structure | Pay-as-you-go or subscription-based pricing models | High initial investment, low ongoing labor costs |

| Speed & Scalability | Fast deployment with easy scalability | High throughput but less adaptable to rapid changes |

| Use Cases | Prototyping, small-batch production, variable demand | Mass production, consistent repetitive manufacturing |

| Data Integration | Cloud-based real-time analytics and remote monitoring | Integrated IoT and AI for autonomous decision making |

Which is better?

Factory as a Service (FaaS) provides flexible, on-demand access to manufacturing resources, enabling businesses to scale production without heavy capital investment. Lights-out manufacturing emphasizes fully automated factories operating without human intervention, maximizing efficiency and reducing labor costs. Choosing between FaaS and lights-out manufacturing depends on factors like production volume, customization needs, and investment capacity.

Connection

Factory as a Service (FaaS) integrates cloud-based platforms with automated production systems to enable lights-out manufacturing, where factories operate autonomously without human intervention. This connection enhances efficiency by leveraging remote monitoring, AI-driven process optimization, and real-time data analytics. The synergy of FaaS and lights-out manufacturing reduces operational costs, improves scalability, and accelerates time-to-market in modern industrial production.

Key Terms

Automation

Lights-out manufacturing relies on fully automated production processes operating without human intervention, maximizing efficiency and minimizing downtime through advanced robotics and AI-driven control systems. Factory as a Service (FaaS) offers flexible, on-demand manufacturing solutions by integrating automation with cloud-based management, enabling clients to scale production dynamically while reducing capital expenditure. Explore how automation transforms traditional manufacturing models to optimize productivity and operational agility.

Cloud Computing

Lights-out manufacturing employs fully automated production with minimal human intervention, leveraging IoT sensors and AI-driven robotics to enhance efficiency and reduce downtime. Factory as a Service (FaaS) integrates cloud computing platforms to offer on-demand manufacturing capabilities, enabling businesses to scale production remotely while maintaining real-time monitoring and data analytics. Explore more about how cloud innovations are transforming industrial automation and supply chain agility.

Robotics

Lights-out manufacturing leverages fully automated robotic systems operating without human intervention, maximizing efficiency and minimizing operational costs through continuous production. Factory as a Service (FaaS) incorporates robotics within a flexible, on-demand manufacturing model, providing scalable and customizable production solutions accessible via cloud platforms. Explore how robotics transform both lights-out manufacturing and FaaS to unlock advanced automation and agile production capabilities.

Source and External Links

Lights-out factory - Siemens Digital Industries Software - A lights-out factory operates with minimal or no human intervention, enabled by advanced automation, robotics, and manufacturing operations management software that orchestrates and monitors production remotely.

What is Lights Out Manufacturing? Exploring Full Automation - Lights-out manufacturing uses fully automated technology to run production around the clock with little to no human presence, reducing labor costs and improving consistency and safety.

What is "Lights Out" Dark Manufacturing? - Dark or lights-out manufacturing relies on robotics, AI, and IoT systems to achieve near-total automation, maximizing efficiency and minimizing errors while addressing labor shortages and rising costs.

dowidth.com

dowidth.com