Industrial symbiosis maximizes resource efficiency by facilitating the exchange of materials, energy, and by-products between interconnected industries, reducing waste and environmental impact. Life cycle assessment (LCA) systematically evaluates the environmental aspects and potential impacts associated with a product from raw material extraction through disposal. Explore the benefits and distinctions between industrial symbiosis and LCA to enhance sustainable manufacturing practices.

Why it is important

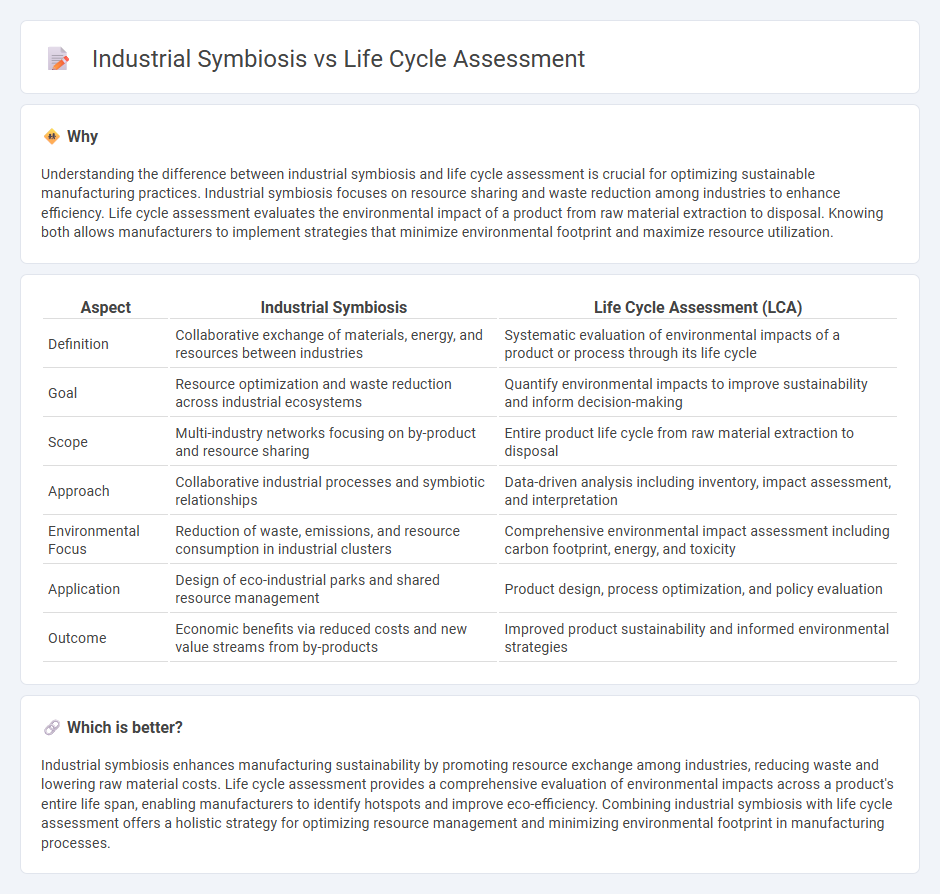

Understanding the difference between industrial symbiosis and life cycle assessment is crucial for optimizing sustainable manufacturing practices. Industrial symbiosis focuses on resource sharing and waste reduction among industries to enhance efficiency. Life cycle assessment evaluates the environmental impact of a product from raw material extraction to disposal. Knowing both allows manufacturers to implement strategies that minimize environmental footprint and maximize resource utilization.

Comparison Table

| Aspect | Industrial Symbiosis | Life Cycle Assessment (LCA) |

|---|---|---|

| Definition | Collaborative exchange of materials, energy, and resources between industries | Systematic evaluation of environmental impacts of a product or process through its life cycle |

| Goal | Resource optimization and waste reduction across industrial ecosystems | Quantify environmental impacts to improve sustainability and inform decision-making |

| Scope | Multi-industry networks focusing on by-product and resource sharing | Entire product life cycle from raw material extraction to disposal |

| Approach | Collaborative industrial processes and symbiotic relationships | Data-driven analysis including inventory, impact assessment, and interpretation |

| Environmental Focus | Reduction of waste, emissions, and resource consumption in industrial clusters | Comprehensive environmental impact assessment including carbon footprint, energy, and toxicity |

| Application | Design of eco-industrial parks and shared resource management | Product design, process optimization, and policy evaluation |

| Outcome | Economic benefits via reduced costs and new value streams from by-products | Improved product sustainability and informed environmental strategies |

Which is better?

Industrial symbiosis enhances manufacturing sustainability by promoting resource exchange among industries, reducing waste and lowering raw material costs. Life cycle assessment provides a comprehensive evaluation of environmental impacts across a product's entire life span, enabling manufacturers to identify hotspots and improve eco-efficiency. Combining industrial symbiosis with life cycle assessment offers a holistic strategy for optimizing resource management and minimizing environmental footprint in manufacturing processes.

Connection

Industrial symbiosis enhances manufacturing sustainability by facilitating resource sharing and waste exchange among industries, thereby reducing environmental impact. Life cycle assessment (LCA) evaluates these environmental impacts throughout the product's entire life span, from raw material extraction to disposal, providing critical data for optimizing industrial symbiosis strategies. The integration of LCA in industrial symbiosis supports decision-making processes for minimizing energy consumption, emissions, and waste production in manufacturing systems.

Key Terms

**Life Cycle Assessment:**

Life Cycle Assessment (LCA) systematically evaluates the environmental impacts of a product or process throughout its entire lifespan, from raw material extraction to disposal, quantifying emissions, resource use, and energy consumption. It contrasts with Industrial Symbiosis, which emphasizes resource sharing and waste exchange among industries to minimize environmental footprint. Discover how LCA contributes to sustainable decision-making and efficiency improvements in industrial operations.

Environmental Impact

Life cycle assessment (LCA) quantitatively evaluates the environmental impacts of a product or process from raw material extraction to disposal, using metrics such as carbon footprint, water usage, and energy consumption. Industrial symbiosis emphasizes resource efficiency by enabling waste or by-products from one industry to serve as inputs for another, significantly reducing overall emissions and resource depletion. Explore how integrating LCA with industrial symbiosis can optimize sustainability strategies in industrial ecosystems.

Inventory Analysis

Life Cycle Assessment (LCA) Inventory Analysis involves quantifying energy and material inputs and outputs throughout a product's life cycle to identify environmental impacts. In contrast, Industrial Symbiosis focuses on optimizing resource exchange between industries by tracking material and energy flows to minimize waste and enhance resource efficiency. Explore further to understand how these approaches uniquely contribute to sustainable industrial practices.

Source and External Links

Life Cycle Assessment (LCA) explained - PRe Sustainability - Life cycle assessment (LCA) is a method to evaluate the environmental impacts of a product, process, or service throughout its entire lifecycle, including raw material extraction, production, use, and disposal, helping businesses improve sustainability and strategic planning.

Life Cycle Assessment (LCA) - Everything you need to know - LCA consists of four phases defined by ISO standards: goal and scope definition, inventory analysis, impact assessment, and interpretation, supporting detailed analysis of environmental effects from production to waste or recycling.

Life-cycle assessment - Wikipedia - LCA is a standardized methodology (ISO 14040 and 14044) that assesses environmental impacts through all stages of a product, process, or service, from cradle to grave, by analyzing resource use and emissions to improve environmental profiles.

dowidth.com

dowidth.com