Industrial metaverse integrates virtual and augmented reality with manufacturing processes, enhancing design, training, and remote collaboration through immersive digital twins and real-time data visualization. Robotics focuses on automating physical tasks on the factory floor, boosting efficiency, precision, and safety with autonomous machines and robotic arms. Explore how these technologies are revolutionizing manufacturing by combining digital innovation with automation.

Why it is important

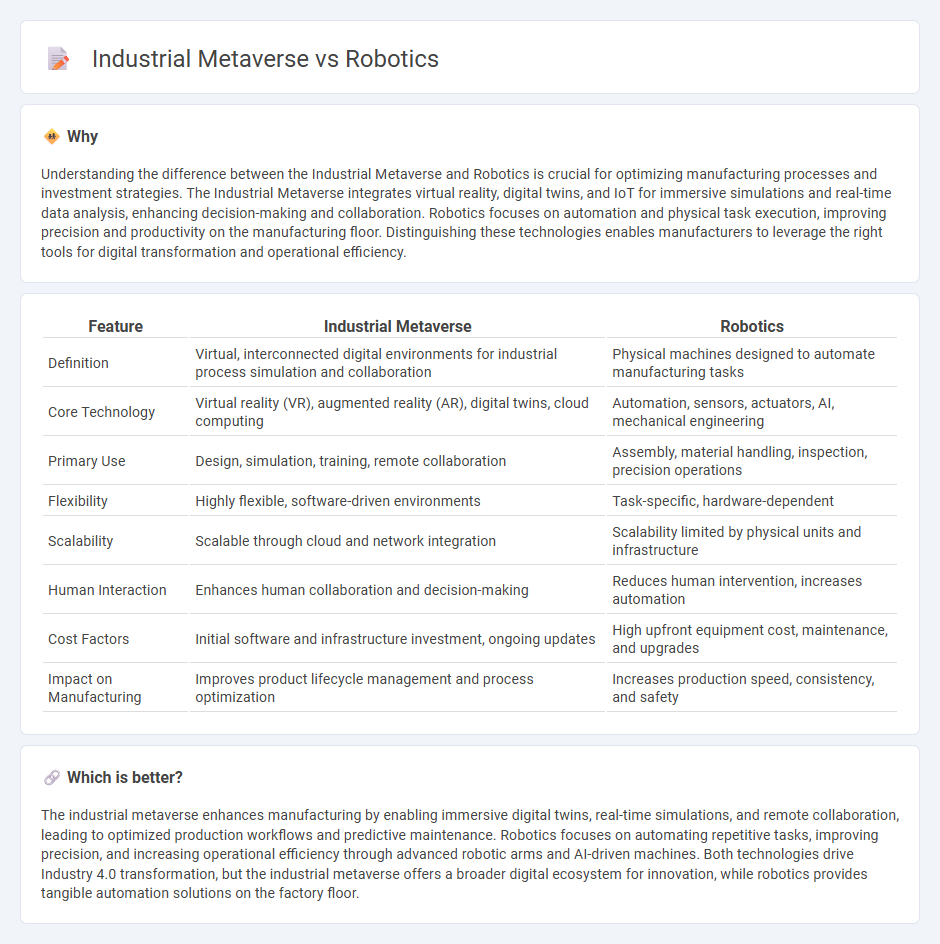

Understanding the difference between the Industrial Metaverse and Robotics is crucial for optimizing manufacturing processes and investment strategies. The Industrial Metaverse integrates virtual reality, digital twins, and IoT for immersive simulations and real-time data analysis, enhancing decision-making and collaboration. Robotics focuses on automation and physical task execution, improving precision and productivity on the manufacturing floor. Distinguishing these technologies enables manufacturers to leverage the right tools for digital transformation and operational efficiency.

Comparison Table

| Feature | Industrial Metaverse | Robotics |

|---|---|---|

| Definition | Virtual, interconnected digital environments for industrial process simulation and collaboration | Physical machines designed to automate manufacturing tasks |

| Core Technology | Virtual reality (VR), augmented reality (AR), digital twins, cloud computing | Automation, sensors, actuators, AI, mechanical engineering |

| Primary Use | Design, simulation, training, remote collaboration | Assembly, material handling, inspection, precision operations |

| Flexibility | Highly flexible, software-driven environments | Task-specific, hardware-dependent |

| Scalability | Scalable through cloud and network integration | Scalability limited by physical units and infrastructure |

| Human Interaction | Enhances human collaboration and decision-making | Reduces human intervention, increases automation |

| Cost Factors | Initial software and infrastructure investment, ongoing updates | High upfront equipment cost, maintenance, and upgrades |

| Impact on Manufacturing | Improves product lifecycle management and process optimization | Increases production speed, consistency, and safety |

Which is better?

The industrial metaverse enhances manufacturing by enabling immersive digital twins, real-time simulations, and remote collaboration, leading to optimized production workflows and predictive maintenance. Robotics focuses on automating repetitive tasks, improving precision, and increasing operational efficiency through advanced robotic arms and AI-driven machines. Both technologies drive Industry 4.0 transformation, but the industrial metaverse offers a broader digital ecosystem for innovation, while robotics provides tangible automation solutions on the factory floor.

Connection

The Industrial Metaverse integrates robotics by creating immersive digital twins of manufacturing environments, enabling real-time simulation and optimization of robotic processes. Robotics enhances automation and precision in production lines, while the Industrial Metaverse provides a virtual platform for monitoring, troubleshooting, and training without halting operations. This connection accelerates innovation, reduces downtime, and improves overall manufacturing efficiency.

Key Terms

Automation

Robotics revolutionizes automation by integrating physical machines with sophisticated control systems to perform tasks precisely and efficiently, reducing human labor in manufacturing. The industrial metaverse enhances automation through immersive digital twins and AI-driven simulations that optimize workflows and predictive maintenance in virtual environments. Explore how combining robotics and the industrial metaverse can transform automation and drive industry 4.0 innovations.

Digital Twin

Digital twin technology serves as a crucial link between robotics and the industrial metaverse by creating real-time virtual replicas of physical assets, enabling enhanced monitoring and predictive maintenance. Robotics systems integrated with digital twins optimize operational efficiency through precise simulations and data-driven decision-making within industrial environments. Explore how digital twin advancements are transforming robotics and the industrial metaverse to unlock new levels of productivity and innovation.

Cyber-Physical Systems

Cyber-Physical Systems (CPS) integrate robotics with the Industrial Metaverse to enhance automation, real-time data exchange, and digital twins, driving smarter manufacturing processes. Robotics provides physical actions and sensor data, while the Industrial Metaverse offers immersive simulations and collaborative virtual environments for optimizing production workflows. Explore how CPS bridges these technologies to revolutionize industrial operations and unlock future potential.

Source and External Links

Robotics: What Are Robots? - This guide provides an overview of robotics, including different types of robots and their applications across industries.

Robotics - Wikipedia - This article covers the interdisciplinary study and practice of designing, constructing, operating, and using robots.

International Federation of Robotics - A professional organization promoting and supporting the robotics industry worldwide, organizing conferences and exhibitions.

dowidth.com

dowidth.com