Digital twinning offers real-time simulation and predictive analytics by creating virtual replicas of physical manufacturing processes, enhancing operational efficiency and proactive maintenance. SCADA systems focus on real-time monitoring and control of industrial equipment, providing centralized data acquisition and process automation. Explore how integrating digital twins with SCADA can revolutionize manufacturing productivity and reliability.

Why it is important

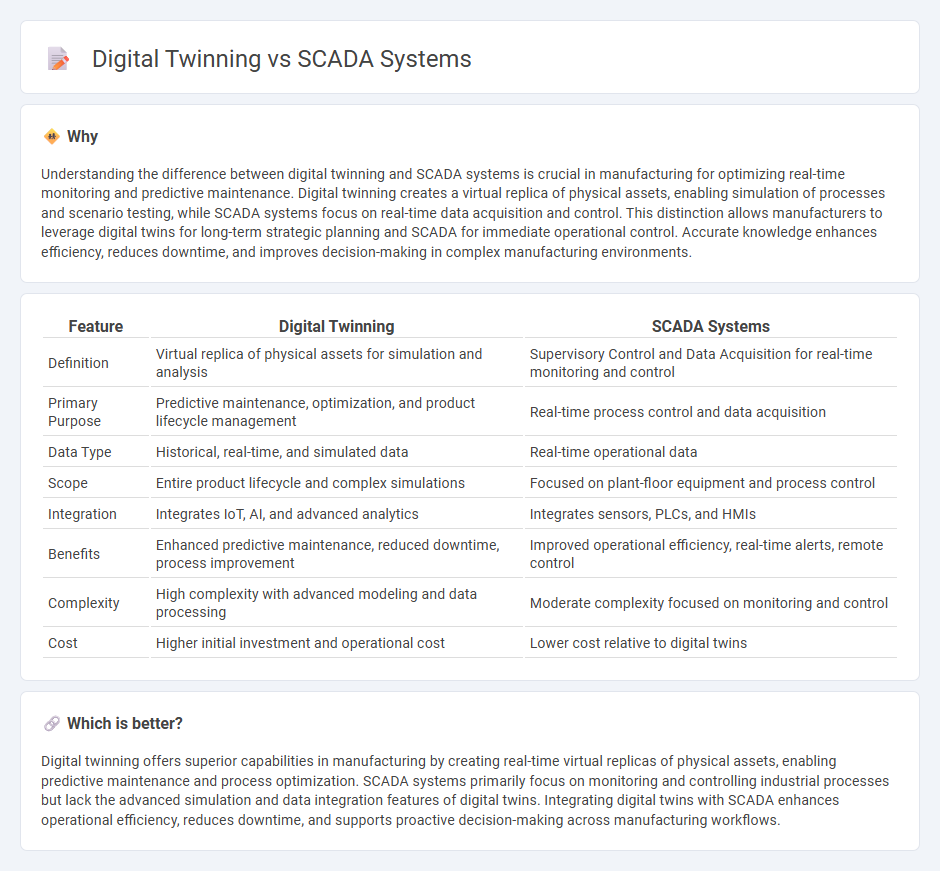

Understanding the difference between digital twinning and SCADA systems is crucial in manufacturing for optimizing real-time monitoring and predictive maintenance. Digital twinning creates a virtual replica of physical assets, enabling simulation of processes and scenario testing, while SCADA systems focus on real-time data acquisition and control. This distinction allows manufacturers to leverage digital twins for long-term strategic planning and SCADA for immediate operational control. Accurate knowledge enhances efficiency, reduces downtime, and improves decision-making in complex manufacturing environments.

Comparison Table

| Feature | Digital Twinning | SCADA Systems |

|---|---|---|

| Definition | Virtual replica of physical assets for simulation and analysis | Supervisory Control and Data Acquisition for real-time monitoring and control |

| Primary Purpose | Predictive maintenance, optimization, and product lifecycle management | Real-time process control and data acquisition |

| Data Type | Historical, real-time, and simulated data | Real-time operational data |

| Scope | Entire product lifecycle and complex simulations | Focused on plant-floor equipment and process control |

| Integration | Integrates IoT, AI, and advanced analytics | Integrates sensors, PLCs, and HMIs |

| Benefits | Enhanced predictive maintenance, reduced downtime, process improvement | Improved operational efficiency, real-time alerts, remote control |

| Complexity | High complexity with advanced modeling and data processing | Moderate complexity focused on monitoring and control |

| Cost | Higher initial investment and operational cost | Lower cost relative to digital twins |

Which is better?

Digital twinning offers superior capabilities in manufacturing by creating real-time virtual replicas of physical assets, enabling predictive maintenance and process optimization. SCADA systems primarily focus on monitoring and controlling industrial processes but lack the advanced simulation and data integration features of digital twins. Integrating digital twins with SCADA enhances operational efficiency, reduces downtime, and supports proactive decision-making across manufacturing workflows.

Connection

Digital twinning and SCADA systems are connected through their roles in enhancing manufacturing efficiency and real-time monitoring. SCADA systems collect and control data from manufacturing processes, which digital twins use to create accurate virtual models for simulation and predictive maintenance. This integration enables manufacturers to optimize operations, reduce downtime, and improve decision-making by leveraging real-time data and virtual scenario testing.

Key Terms

Real-time monitoring

SCADA systems provide real-time monitoring by collecting and analyzing data from industrial equipment to ensure operational efficiency and safety. Digital twinning enhances this process by creating a virtual replica of physical assets, enabling predictive analytics and scenario testing in real time. Discover how integrating digital twinning with SCADA transforms industrial monitoring and decision-making.

Virtual simulation

SCADA systems primarily monitor and control real-time industrial processes, collecting data for operational efficiency and safety, while digital twinning creates dynamic virtual simulations that mirror physical assets for predictive analysis and optimization. Virtual simulation in digital twins enables detailed scenario testing and performance forecasting, surpassing the reactive capabilities of traditional SCADA technology. Discover how integrating these technologies revolutionizes industrial automation through advanced virtual simulation.

Data integration

SCADA systems primarily collect real-time operational data from industrial equipment, enabling monitoring and control within manufacturing and infrastructure environments. Digital twinning integrates diverse data sources, including SCADA input, IoT sensors, and historical analytics, to create a comprehensive virtual model for simulation and predictive maintenance. Explore how advanced data integration techniques enhance both SCADA functionality and digital twin accuracy for optimized asset management.

Source and External Links

What is SCADA system and how does it work? - AVEVA - SCADA (Supervisory Control and Data Acquisition) systems use software and hardware to enable industrial organizations to control processes and equipment by collecting data via RTUs or PLCs, displaying it through HMIs, and allowing operators to monitor and adjust operations in real time for improved efficiency and response to emergencies.

SCADA - Wikipedia - SCADA systems control and monitor physical processes through supervisory computers, remote terminal units, and human-machine interfaces, managing infrastructure such as electricity transmission and water distribution with robust communication networks often designed for redundancy and extreme environmental conditions.

What is SCADA? Supervisory Control and Data Acquisition - SCADA combines software and hardware to monitor and control industrial processes by interfacing with plant-floor machinery, offering real-time data interaction, recording events, and enabling operators to make informed decisions to maintain efficiency and reduce downtime.

dowidth.com

dowidth.com