Dark factories leverage fully automated systems operating without human presence, maximizing efficiency and minimizing operational costs through continuous production cycles. Digital twins create virtual replicas of physical manufacturing environments, enabling real-time monitoring, simulation, and predictive maintenance to optimize factory performance. Explore how integrating dark factory concepts with digital twin technology can revolutionize manufacturing processes and drive innovation.

Why it is important

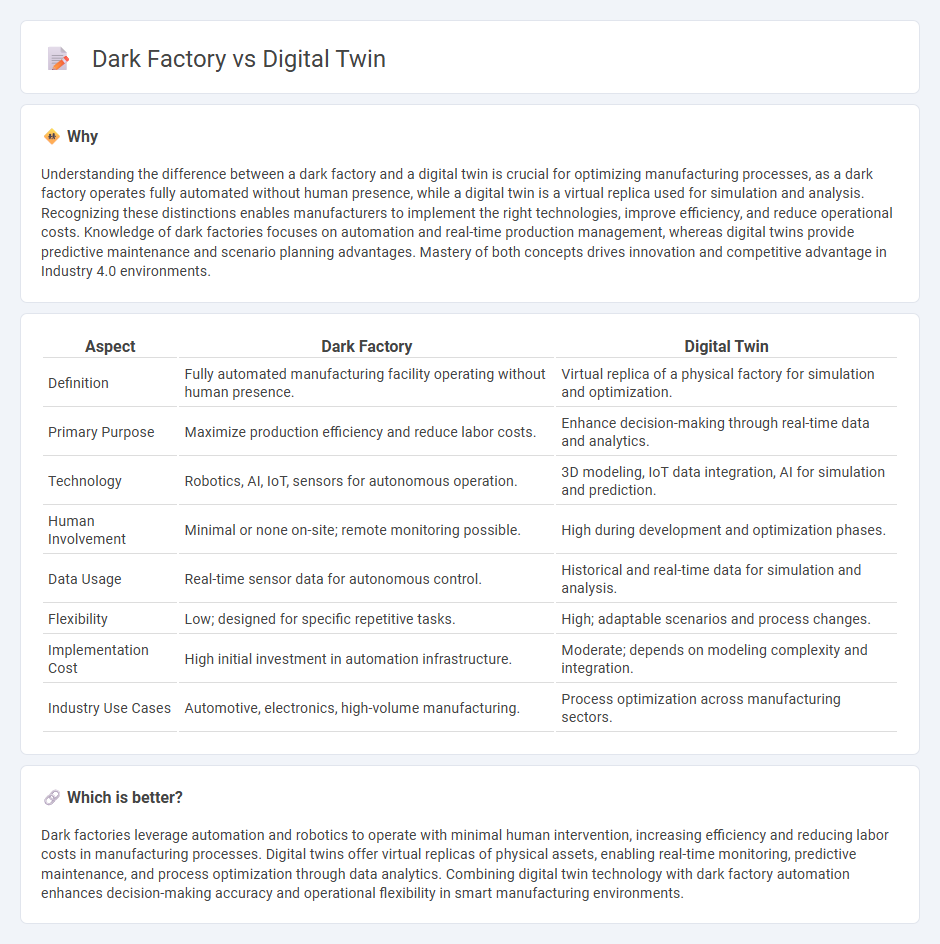

Understanding the difference between a dark factory and a digital twin is crucial for optimizing manufacturing processes, as a dark factory operates fully automated without human presence, while a digital twin is a virtual replica used for simulation and analysis. Recognizing these distinctions enables manufacturers to implement the right technologies, improve efficiency, and reduce operational costs. Knowledge of dark factories focuses on automation and real-time production management, whereas digital twins provide predictive maintenance and scenario planning advantages. Mastery of both concepts drives innovation and competitive advantage in Industry 4.0 environments.

Comparison Table

| Aspect | Dark Factory | Digital Twin |

|---|---|---|

| Definition | Fully automated manufacturing facility operating without human presence. | Virtual replica of a physical factory for simulation and optimization. |

| Primary Purpose | Maximize production efficiency and reduce labor costs. | Enhance decision-making through real-time data and analytics. |

| Technology | Robotics, AI, IoT, sensors for autonomous operation. | 3D modeling, IoT data integration, AI for simulation and prediction. |

| Human Involvement | Minimal or none on-site; remote monitoring possible. | High during development and optimization phases. |

| Data Usage | Real-time sensor data for autonomous control. | Historical and real-time data for simulation and analysis. |

| Flexibility | Low; designed for specific repetitive tasks. | High; adaptable scenarios and process changes. |

| Implementation Cost | High initial investment in automation infrastructure. | Moderate; depends on modeling complexity and integration. |

| Industry Use Cases | Automotive, electronics, high-volume manufacturing. | Process optimization across manufacturing sectors. |

Which is better?

Dark factories leverage automation and robotics to operate with minimal human intervention, increasing efficiency and reducing labor costs in manufacturing processes. Digital twins offer virtual replicas of physical assets, enabling real-time monitoring, predictive maintenance, and process optimization through data analytics. Combining digital twin technology with dark factory automation enhances decision-making accuracy and operational flexibility in smart manufacturing environments.

Connection

Dark factories leverage automation and robotics to operate with minimal or no human intervention, increasing efficiency and reducing errors in manufacturing processes. Digital twins create virtual replicas of these factories, enabling real-time monitoring, predictive maintenance, and optimization of production workflows. The integration of dark factories with digital twin technology enhances decision-making, reduces downtime, and drives smarter manufacturing operations.

Key Terms

**Digital Twin:**

Digital twins are virtual replicas of physical assets, processes, or systems that enable real-time monitoring, simulation, and optimization through data integration from IoT sensors. Unlike dark factories, which operate autonomously without human presence primarily to reduce labor costs, digital twins focus on enhancing decision-making and predictive maintenance by providing detailed insights into asset performance and potential failures. Explore how digital twins drive innovation in manufacturing, smart cities, and asset management for deeper understanding.

Simulation

Digital twins provide real-time simulation by creating dynamic virtual replicas of physical assets, enabling continuous monitoring and predictive analysis. Dark factories utilize automated simulation to optimize operations without human intervention, emphasizing efficiency through robotics and AI-driven processes. Explore the differences in simulation capabilities to enhance your manufacturing strategy.

Real-time Data

A digital twin leverages real-time data to create a dynamic, virtual replica of physical assets, enabling continuous monitoring, simulation, and predictive maintenance for improved operational efficiency. Dark factories operate autonomously without human presence, relying heavily on real-time sensor data and automation systems to maintain production in controlled environments. Explore the transformative impact of real-time data in optimizing processes through digital twins and dark factories.

Source and External Links

What Is a Digital Twin? | IBM - A digital twin is a virtual representation of a physical object or system updated with real-time data from sensors, used for simulation, analysis, and decision-making throughout the object's lifecycle.

Definition of a Digital Twin - A digital twin is an integrated, data-driven virtual model of real-world entities and processes with synchronized interaction at specified fidelity, enabling continuous improvement and decision-making through real-time and historical data.

Digital twin - Wikipedia - A digital twin is a digital model of a real-world physical product, system, or process that continuously updates with real-time data to simulate, monitor, predict, and optimize its physical counterpart.

dowidth.com

dowidth.com